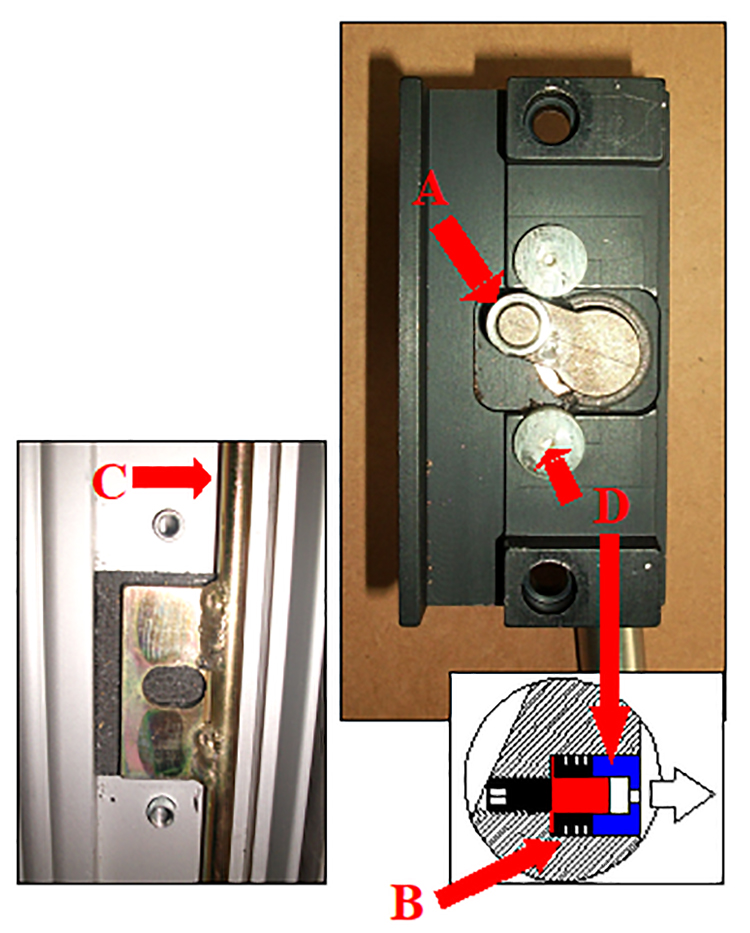

Inside the SteelTrak clamp housing assembly

Before you start

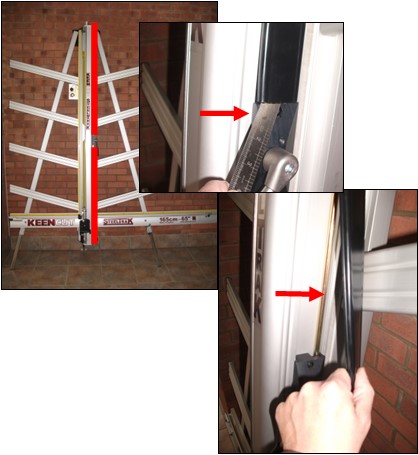

Before starting any work, check the machine is firmly fixed to the wall or freestanding leg and that you have the following equipment:

- A set of steps, high enough to reach the top of the machine

- 5mm (3/16″) Allen key (hex key)

- Small slotted screwdriver or steel ruler

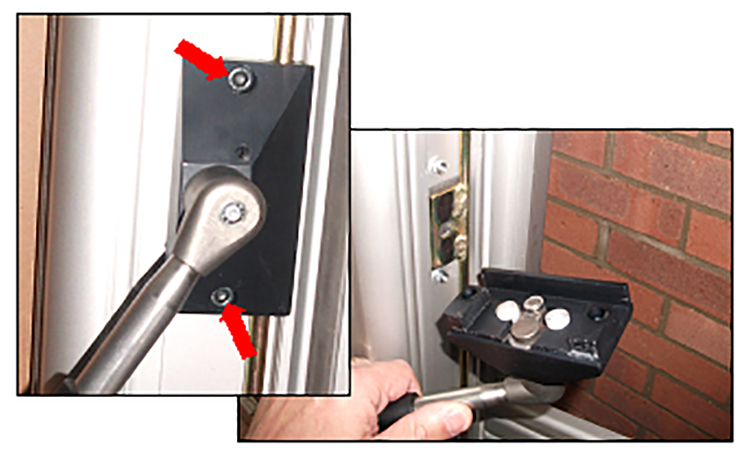

3. Check the clamp housing

The clamp roller (A) should be a snug fit on its spigot. If it is a loose fit, has excessive wear on its outside edge, or is split it should be replaced.

The pressure pads have a series of 7 spring washers (B) behind each of them. The pressure pads will need replacing if they are damaged or worn. to such an extent that there is a 6mm (1/4”) hole visible. Should the spring washers be disturbed, it is essential that they are orientated as shown in the drawing when re-assembled.

Please note: clean any debris from the housing faces but do not lubricate the clamp roller or pressure pads as they must remain clean and dry.

Under the clamp housing assembly is the push rod (C), check the oval hole in the plate is not badly worn, it is not unusual to find a little wear and some rub marks on the face of the plate. Behind the plate is a brake pad (D), which should be fixed to the aluminium slideway. If this needs re-fixing or replacing, use Cyanoacrylate Adhesive e.g superglue and position centrally between the two threaded inserts, as shown.

If replacing the push rod, always replace the adjuster with it. There have been design changes that affect the length of the push rod but compensated for in the adjuster in order to keep the overall length the same.