Evolution3™ Range

Product range

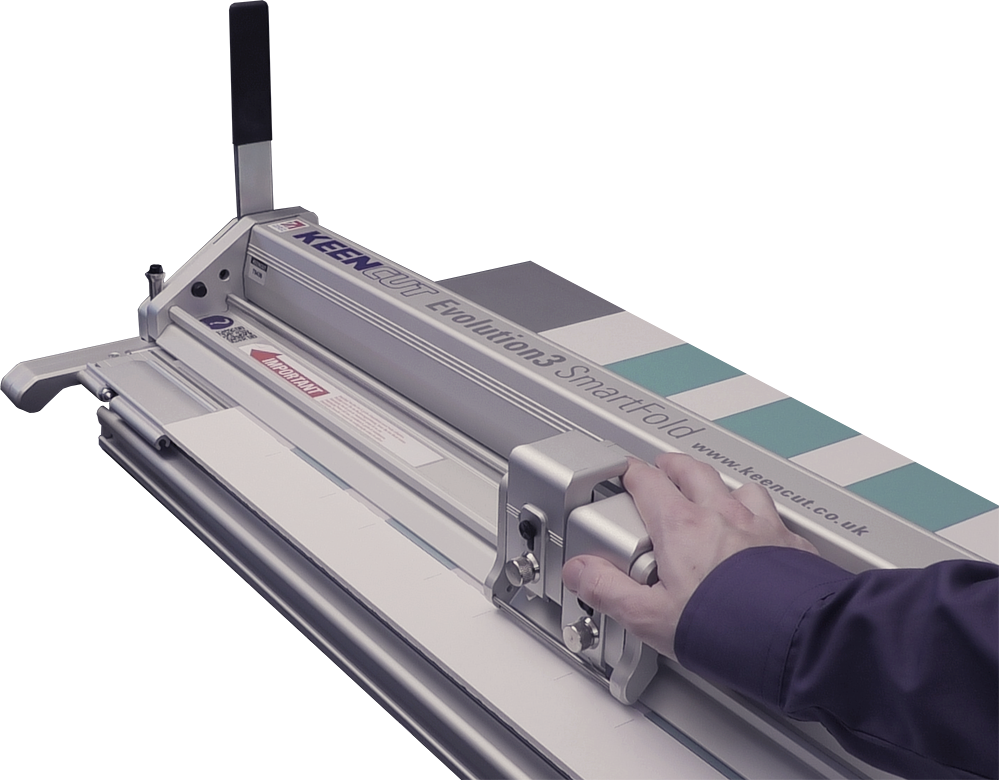

Evolution3 SmartFold

Designed for the busiest production facility, the Evolution3 SmartFold includes all the features of the Evolution3 range with the addition of an integral cutting strip for textiles and fragile materials. The SmartFold can also be folded down to clear the bench and then returned in seconds for immediate use.

Evolution3 BenchTop

Permanently installed for immediate use, the Evolution3 BenchTop is perfect for a busy studio or high use production environment. It includes Keencut’s unique Lift-and-Hover technology and all the precision and productivity enhancing features of the range.

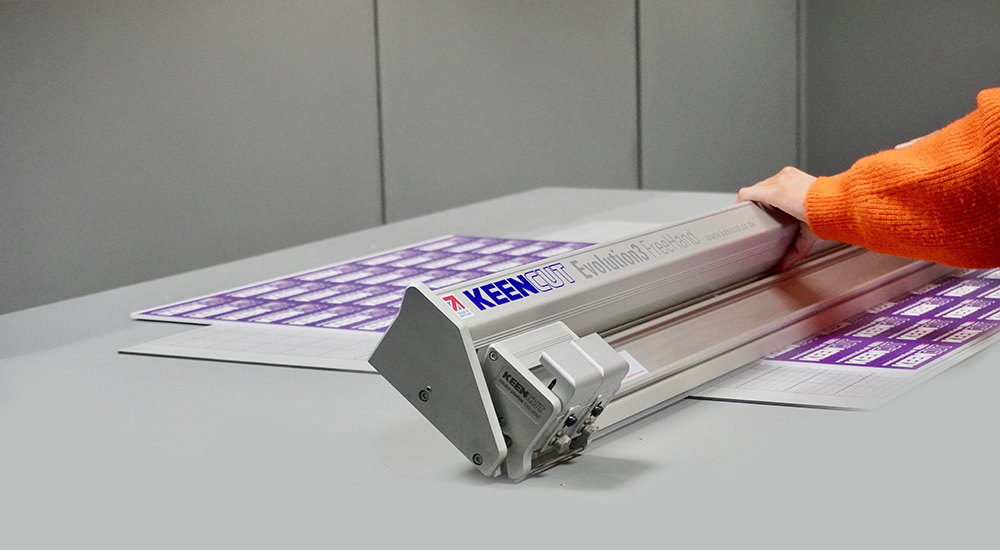

Evolution3 FreeHand

The Evolution3 FreeHand has been designed for those who require the high precision accuracy and superior cutting quality of the Evolution3 range but in a more flexible format. It is perfect if you want the flexibility to move your cutter bar between workbenches or remove it for storage.

Features

Which E3 cutter should I buy?

- Cuts up to 4 times faster than cutting by hand

- Simple, precision alignment reduces waste and saves time

- Cuts with no dust or debris

- Single person operation

- Cutting, scoring, creasing and fabric cutting

- Safety by design

- 5-year guarantee

Lift-and-Hover technology

The Evolution3 SmartFold and BenchTop feature Keencut’s unique Lift-and-Hover (patent pending) technology, which enables single-handed, fast and accurate alignment of all media, irrespective of its thickness. A clutch device within the Lift-and-Hover system enables the clamping bar to be easily raised then lowered, so it hovers just millimetres above the material surface – there is no scooping or sag. The anti-sag mechanism means the cutter bar can be suspended exactly parallel to the media surface over the whole length of the cut with zero sag, even on the longest size of cutter.

Future proof and versatile QuikSwap tool heads

The QuikSwap tool head family gives users the ultimate flexibility. Each tool is designed for a specific purpose, such as general cutting, creasing and fabric cutting and can be attached or detached from the cutter in seconds. You can mount single or multiple tool heads to suit your work and the Graphik tool head is supplied as standard, with other optional QuikSwap tools available to extend your cutting capability.

Guaranteed accuracy

The Evolution3 is the most accurate cutter of its type on the market and is guaranteed to cut within 0.2mm (0.008″) of a straight line for the full length of the cut. The in-built ultra-high precision accuracy, combined with the perfect alignment made possible using the sightline strip, means every butt-jointed panel will join seamlessly. This ultra-high precision accuracy will save you time and money with less waste and fewer mistakes.

Heavy duty reliability

The entire Evolution3 range has been built to last, using high quality materials and well tested engineering principles. The cutting head bearing system and clamping are tough enough to keep perfect blade control, even with the most difficult of materials. Keencut makes the majority of components on its precision CNC machines keeping tolerances and quality under constant control, this assures exceptional accuracy and total reliability.

Five year guarantee

Like all Keencut machines, the Evolution3 is built to give many years of excellent service. All components are manufactured in-house to ensure quality and all Evolution3 cutters come with a five year comprehensive guarantee. Register your product to activate your guarantee >

Materials cut

Semi-rigid materials

Corrugated cardboard ≤ 13mm (1/2″)

PVC foamboard ≤ 13mm (1/2″)

Corrugated plastic ≤ 13mm (1/2″)

Foam centred board ≤ 13mm (1/2″)

Rigid materials

Cast acrylic / Plexiglas ≤ 3mm (3/32″) scoring only

Aluminium composite panel, e.g. DiBond ≤ 3mm (3/32″) Rocker tool head only, for occasional use

Flexible materials

Banners

Pop-ups

Magnetic sheets

Self-adhesive vinyls

Film

Textiles

Delicate materials: tissue paper, wallpaper

Reviews

"The Evolution3 allows us to increase throughput. We complete more work and as such it has a direct and positive impact on our business"

“The Evolution3 allows us to increase throughput. We complete more work and as such it has a direct and positive impact on our business. It’s very, very simple to use and it makes a massive difference to our productivity. I would estimate that it saves us about 10% of production time. The new Lift-and-Hover technology saves us a lot of time. Once the clamp is fully down there is no movement at any point. You do not need to hold onto the handle so you have both hands free to work. The plastic sightline strip is really important, especially when cutting longer pieces of material. You can clearly see the crop marks through the strip so you can very quickly and accurately align the material ready for cutting”