Medium duty utility blades

A double ground edged, reversible blade suitable for cutting all types of materials

Product information >

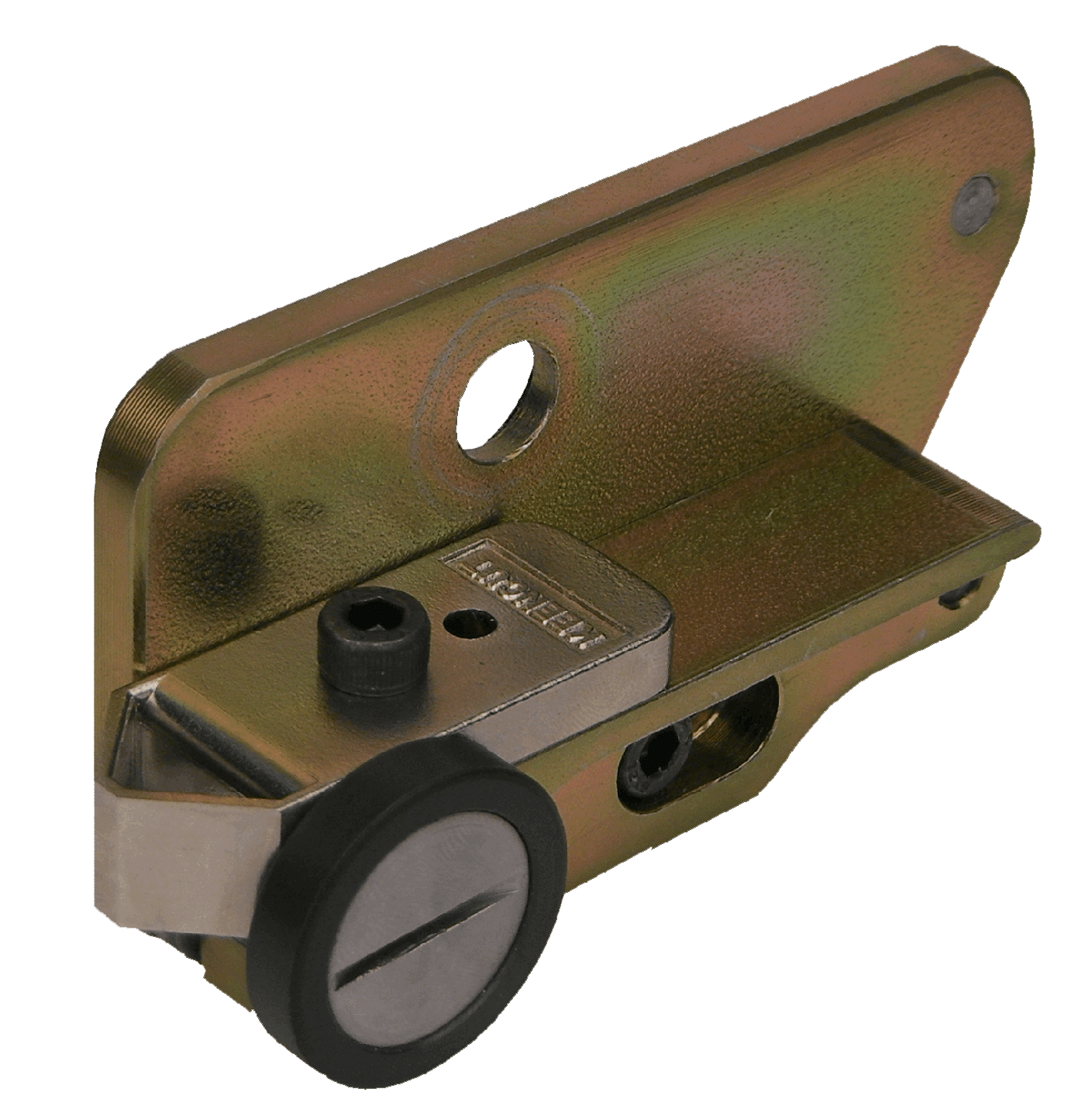

V-groove tool

Enables the SteelTrak to cut V-grooves in composite panels and PVC foamboard, to build sign trays, self-standing displays, exhibition stands and boxes

Product information >

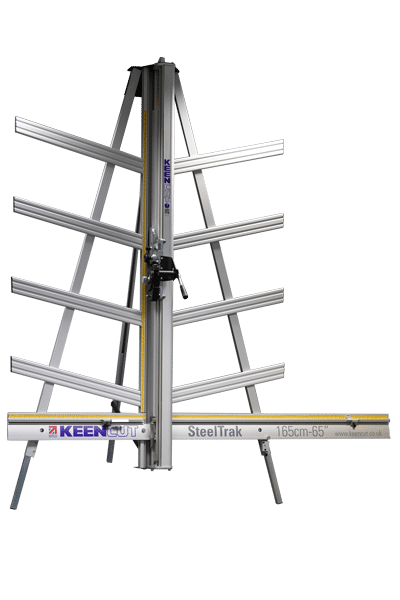

Free standing kit

Enables the SteelTrak to be installed without fixing to a wall

Product information >

Glass cutting kit

Includes everything you need to safely score and break glass on the SteelTrak

Product information >

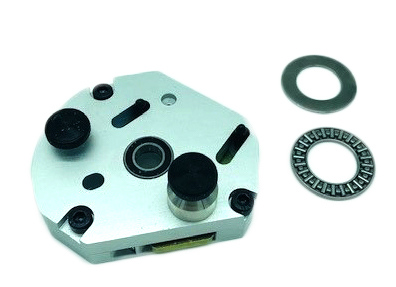

Aluminium cutting head

An additional tool for cutting aluminium sheet material, up to a thickness of 1mm (0.004″), in a single pass

Product information >

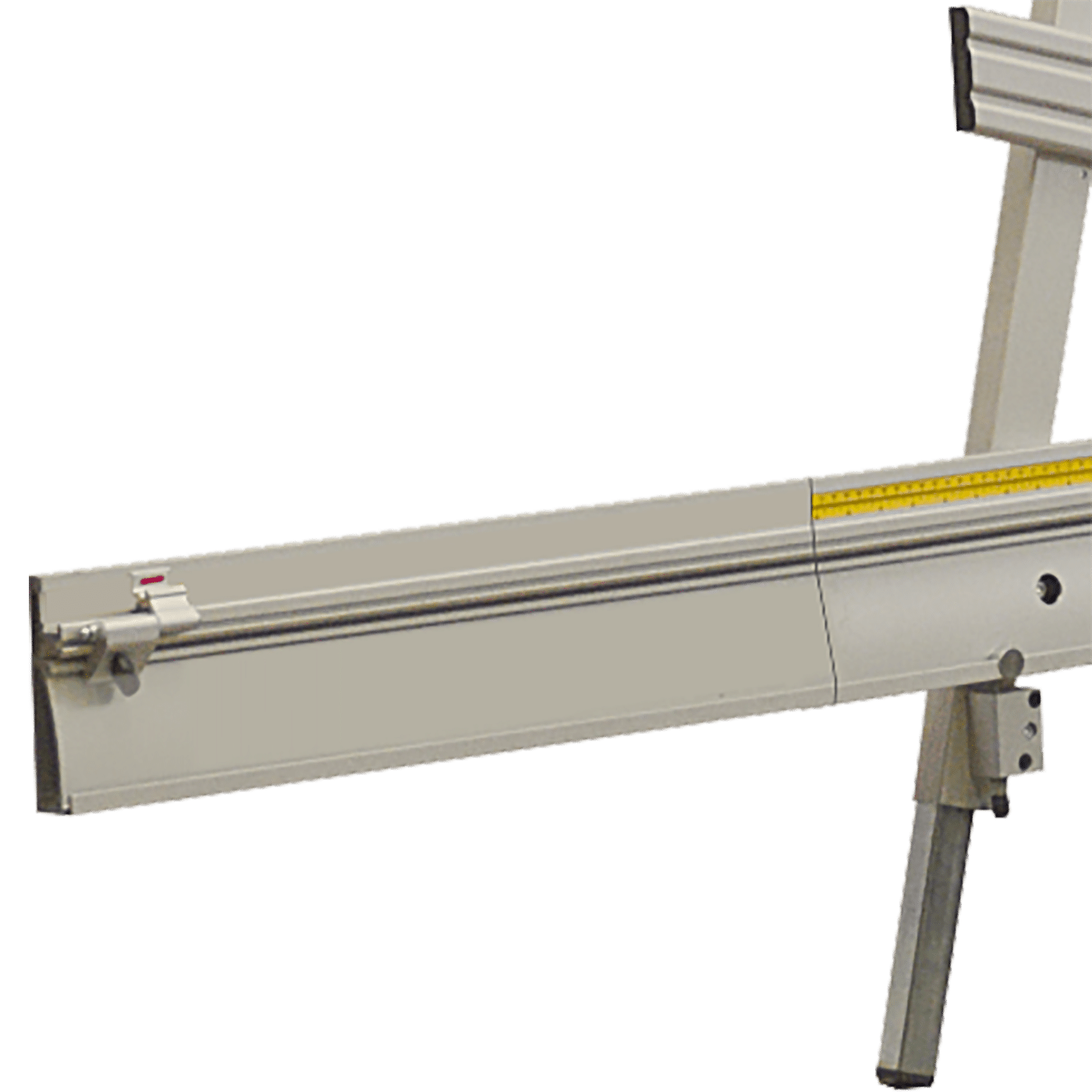

Squaring arm extension

Extends the squaring arm on the left side to support larger boards

Product information >

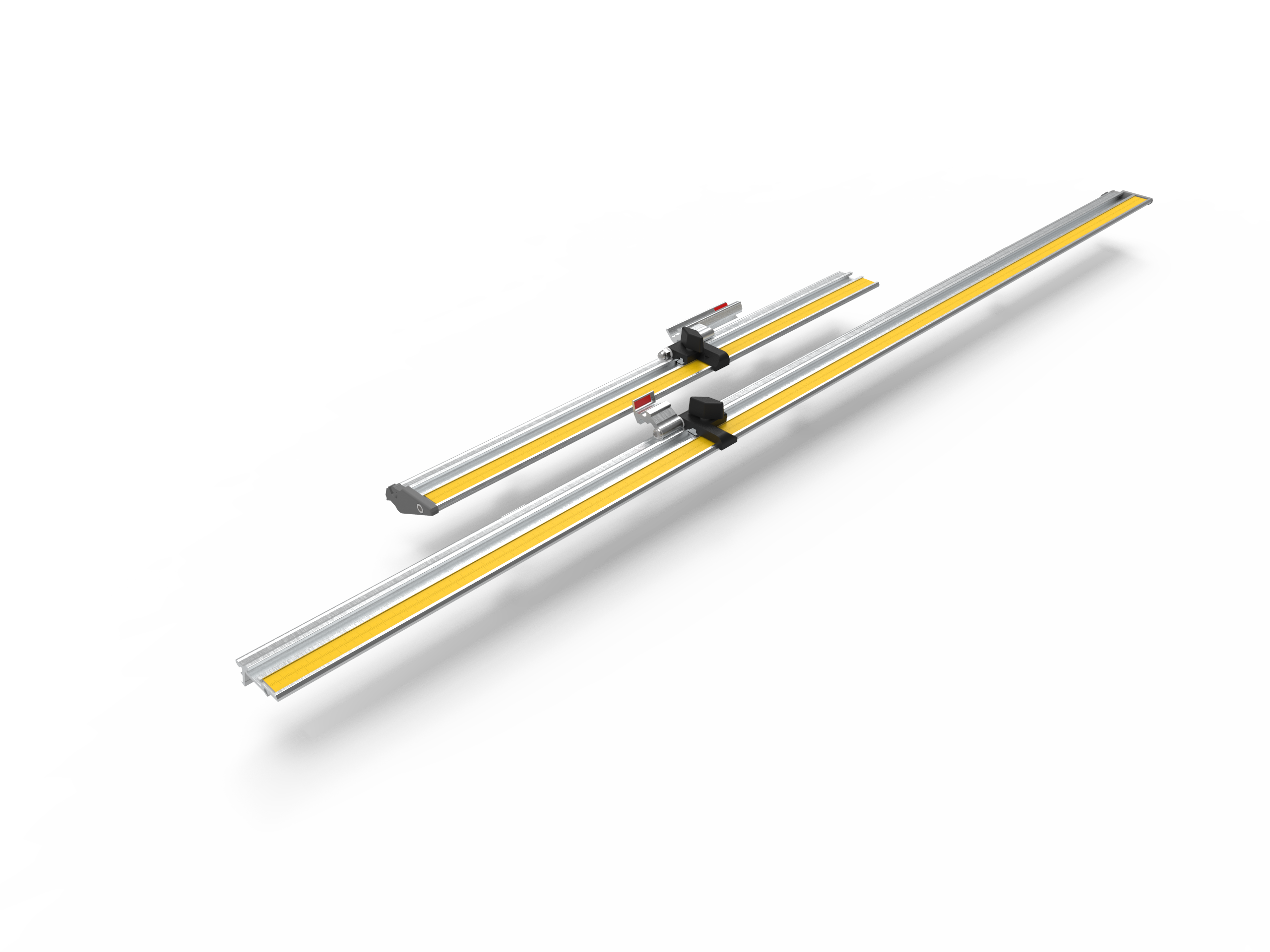

Easy measuring scale

Designed to aid in measuring and aligning rigid and semi-rigid materials.

Product information >