Free standing kit

Enables the Excalibur 6000 to be installed without fixing to a wall

Product information >

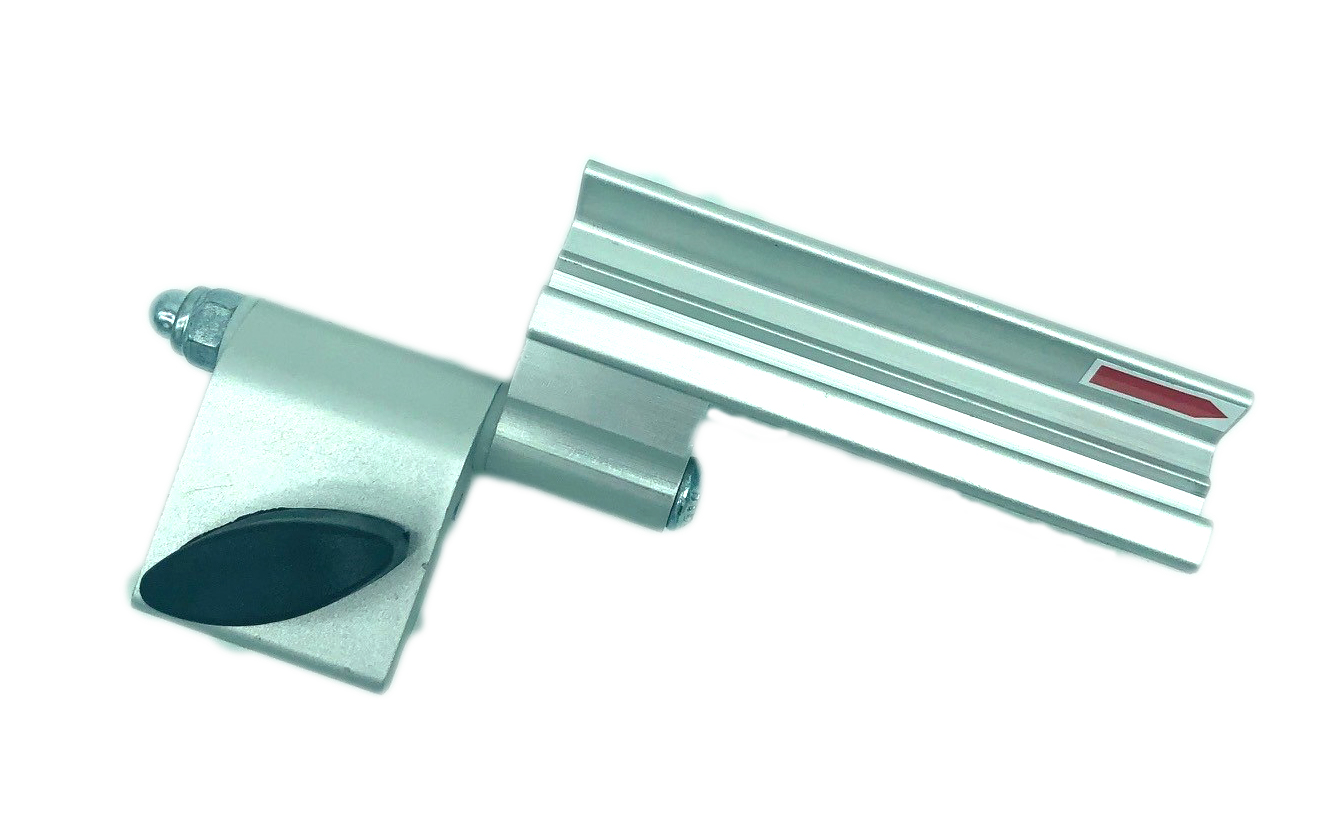

Medium duty utility blades

A double ground edged, reversible blade suitable for cutting all types of materials

Product information >

The Excalibur 6000 cutting tools are permanently mounted for instant selection. In seconds you switch between cutting mount board, hardboard, glass, or acrylic. The four blades cut along the same line, so there’s no need to alter production stops for different materials; it’s quick to set up for one-off jobs or repeatable volume cutting. A one-piece horizontal squaring arm positions the material on either side of the cut line to ensure stability and accuracy. Every material is a perfect frame fit, so you save time, reduce costly mistakes, and prevent waste.

Materials are held firmly with a unique pressure-sensitive clamp to protect delicate surfaces from damage. The PVC-covered arms provide a stabilising non-scratch surface to safeguard expensive materials such as coated glass.

The Easy Measuring Scale is angled at 65 degrees from the vertical to provide easy visibility when setting the flip-in/out measuring stops.

The Excalibur 6000 cuts cleanly, so there is no dust or debris to stick to glass or framing materials.

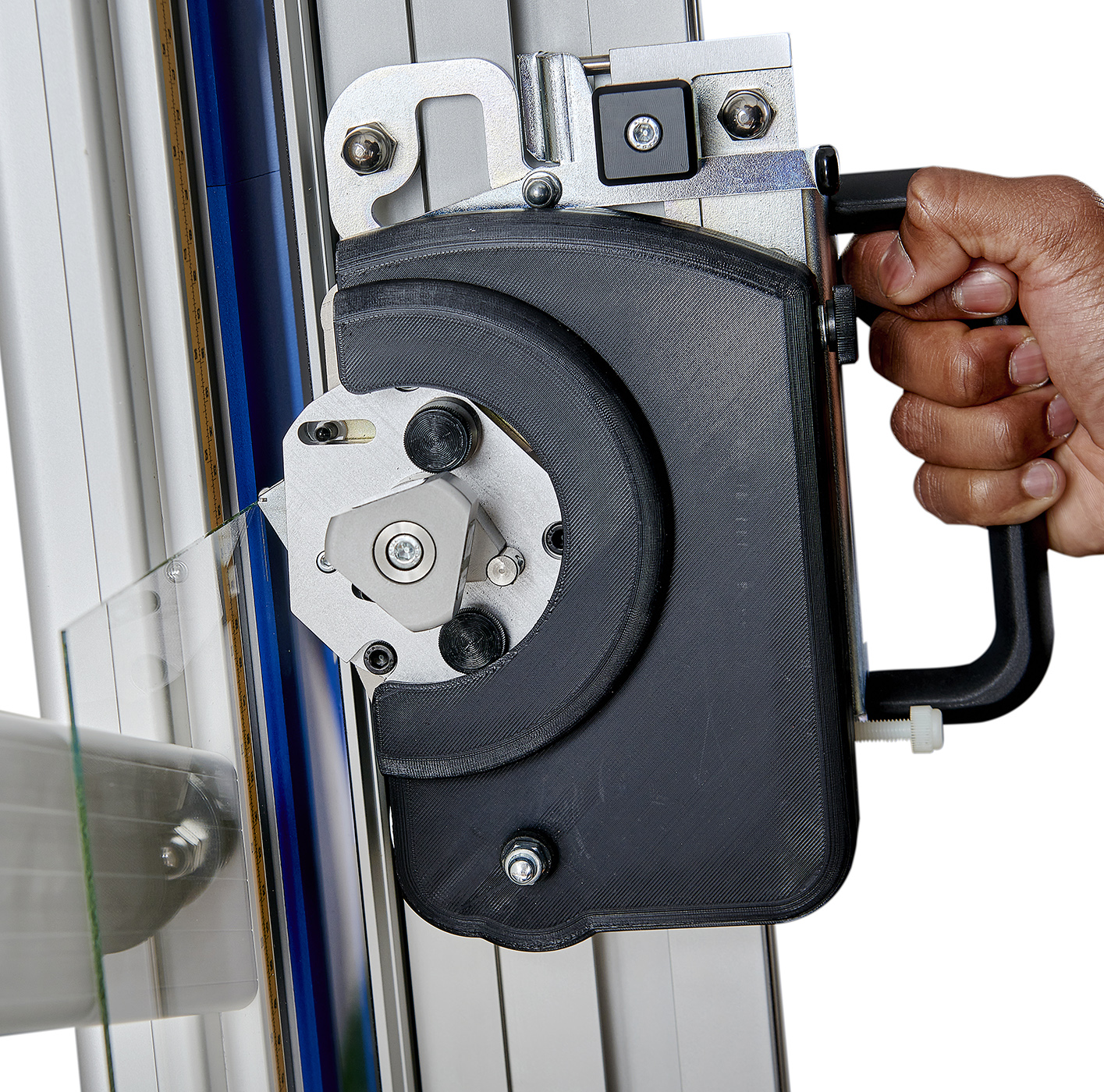

Two heads house four cutting tools. The lower Multi Tool head has a unique ratchet system that provides incremental cutting of thicker materials. The upper Twin Wheel cutter cuts 3mm (1/8″) MDF in a single pass producing a clean finished edge. A balance weight parks the Twin Wheel head at the top of the cutter when not in use.

The Excalibur 6000 is made from top quality components, including steel bearings, to improve durability and ensure zero play. It has a tough proven design with perfect blade control.

The counterbalance weight, upright profile and low friction steel bearing system combine to produce an easy, smooth cut to reduce user fatigue. The integral counterbalance allows the Twin Wheel head to be left in place when loading and unloading materials. Telescopic legs adjust to ensure the most comfortable working height.

The blades automatically disengage when not in use. Glass is safely cut on the machine with minimal effort and no need for additional tools.

The lightweight Excalibur 6000 can be wall mounted or placed on a free-standing kit where wall space is limited.

By manufacturing in-house, with only the highest quality materials, Keencut guarantees that the Excalibur 6000 will provide reliable, long-lasting, and accurate service. All Keencut products have a comprehensive five-year guarantee. Register your product to activate your guarantee >

100 medium duty utility blades

Two glass cutting wheels (1 is mounted)

Twin wheel cutter (mounted)

Wall mounting bracket

Mountboard

Conservation board

MDF ≤ 3mm (3/32″)

Cast acrylic / Plexiglas ≤ 3mm (3/32″)

Coated and uncoated glass ≤ 6mm (1/4″)

Foam centred board ≤ 13mm (1/2″)

Cardboard ≤ 13mm (1/2″)

PVC Foamboard (Forex) ≤ 13mm (1/2”)

Corrugated plastic ≤ 13mm (1/2”)

Enables the Excalibur 6000 to be installed without fixing to a wall

Product information >

A double ground edged, reversible blade suitable for cutting all types of materials

Product information >

Identify the spare parts, accessories and consumables for your machine.

Do you require further information on this product?