Evolution3 SmartFold User Guide – Care and maintenance

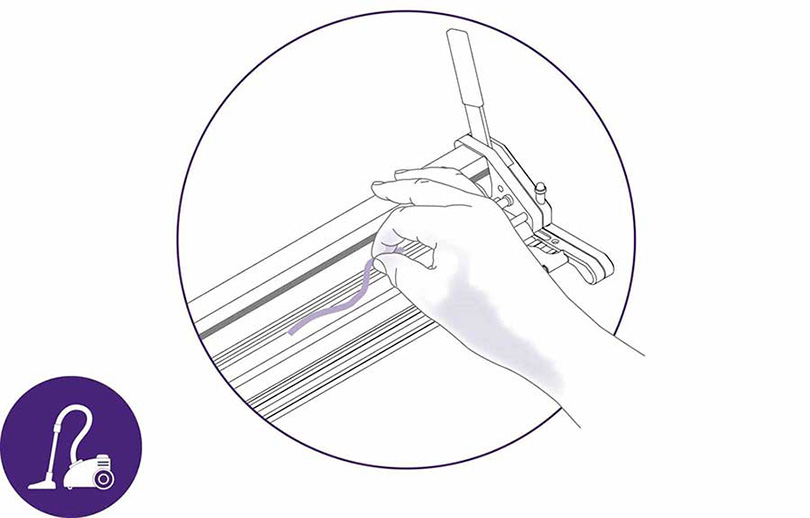

Use a vacuum cleaner to remove any dust and smaller debris.

Frequency: daily as required

Moisten a cloth with diluted detergent to wipe down the cutter bar and base plate, dry with a cloth.

Frequency: weekly

DO NOT use solvents or aggressive cleaning products.

Put a small amount of petroleum jelly (Vaseline) on the scouring surface of a dish washing sponge and rub it up and down the two tracks. Wipe clean any surplus with a dry cloth.

Frequency:

Light use – monthly

Heavy use – weekly

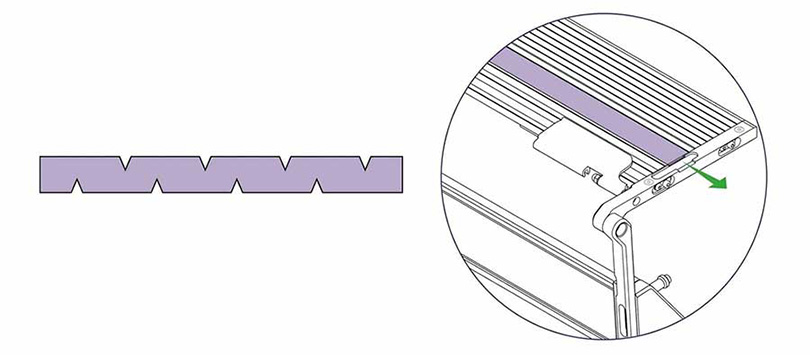

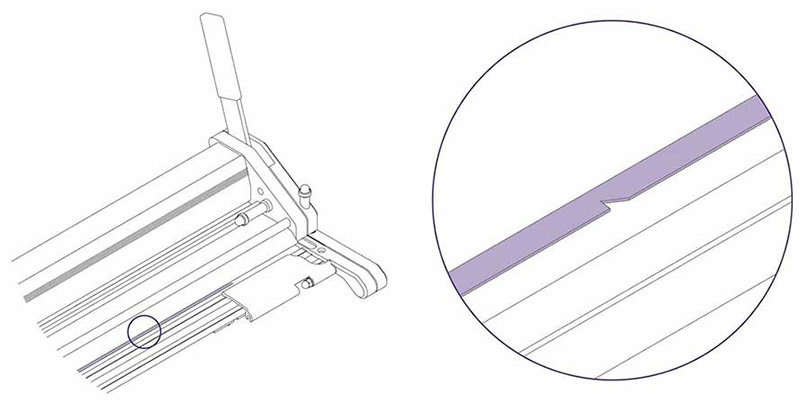

When using the Fabric tool head with the purple plastic cutting strip, it will become scored and require replacing. Adjustment of the cutting pressure to keep it to a minimum for the fabric being cut will help to extend the life of the strip. Check you have used all four cutting tracks on the strip before proceeding.

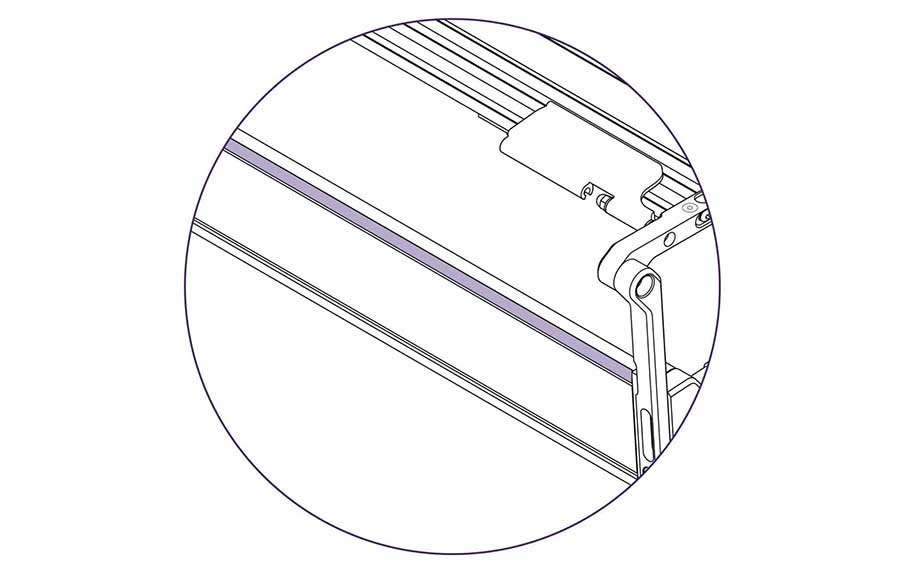

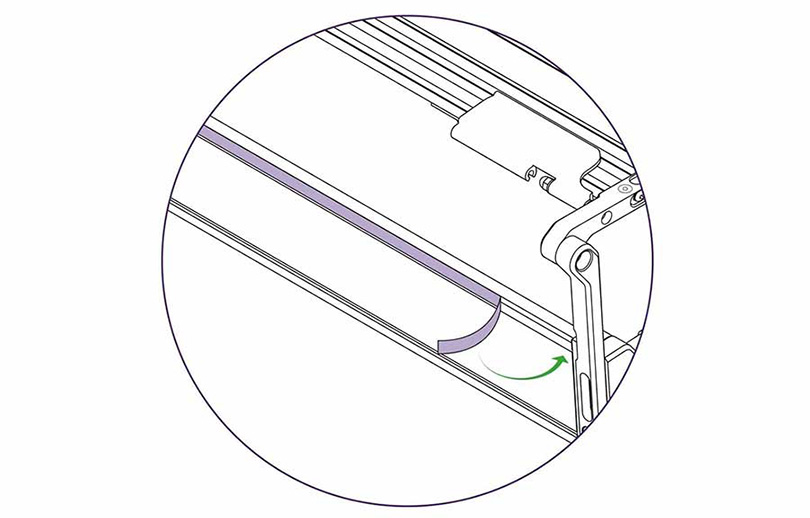

Carefully fold the cutter bar over to reveal the base plate. This may require 2 people.

| Be careful when lifting |

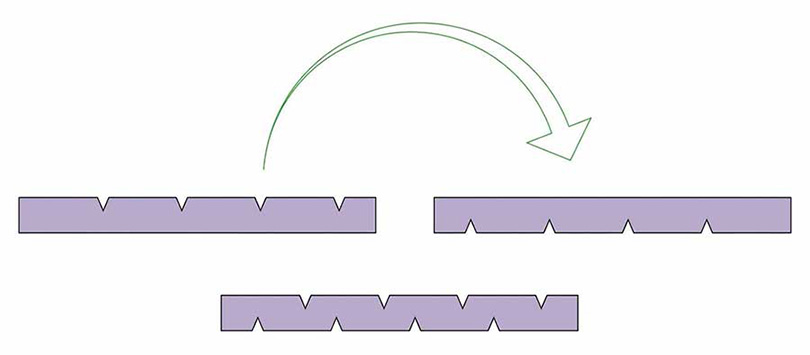

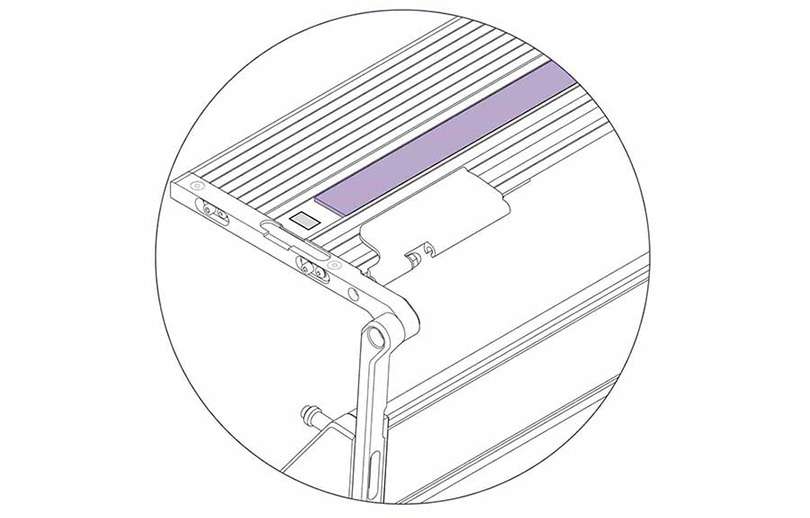

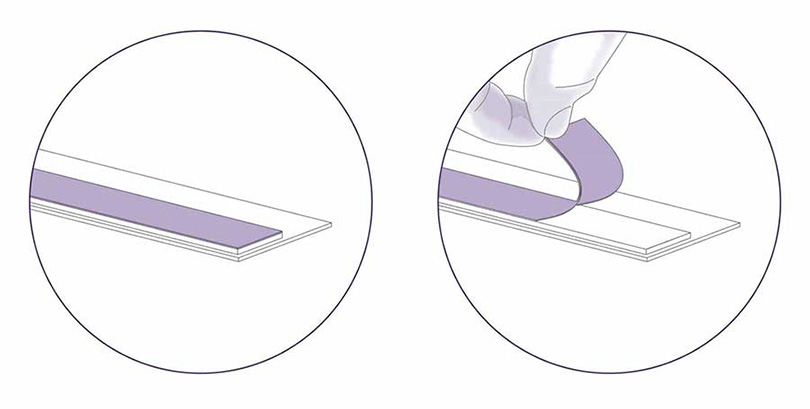

Both sides of the cutting strip can be used, it is important the strip is turned over in the correct orientation. The four tracks are offset to one side so when the strip is turned over correctly the new set of four tracks do not align with the originals.

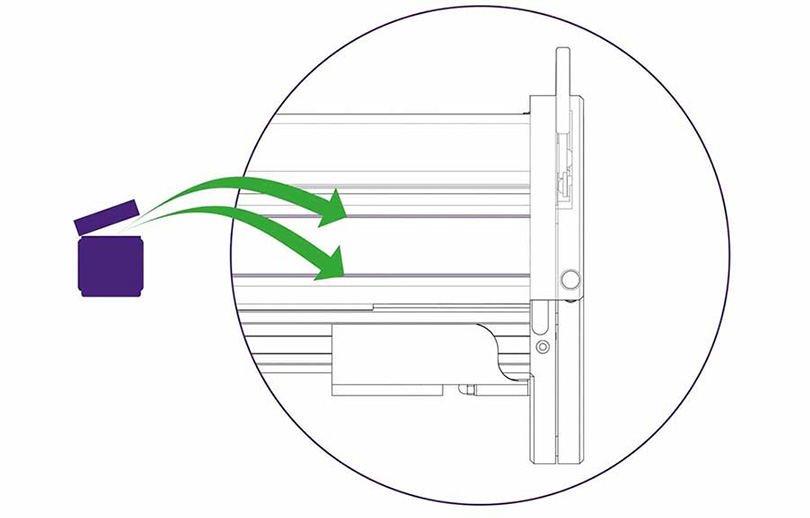

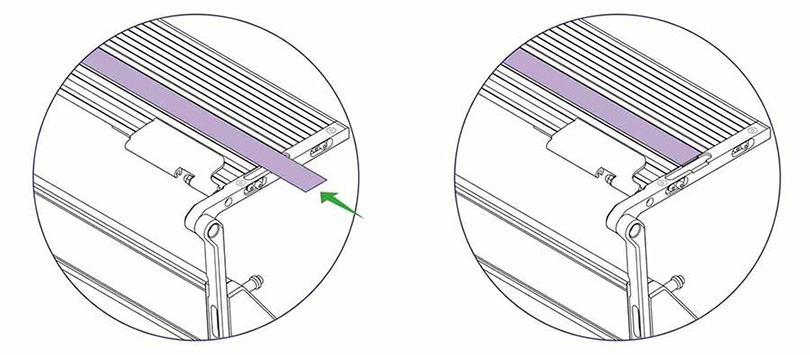

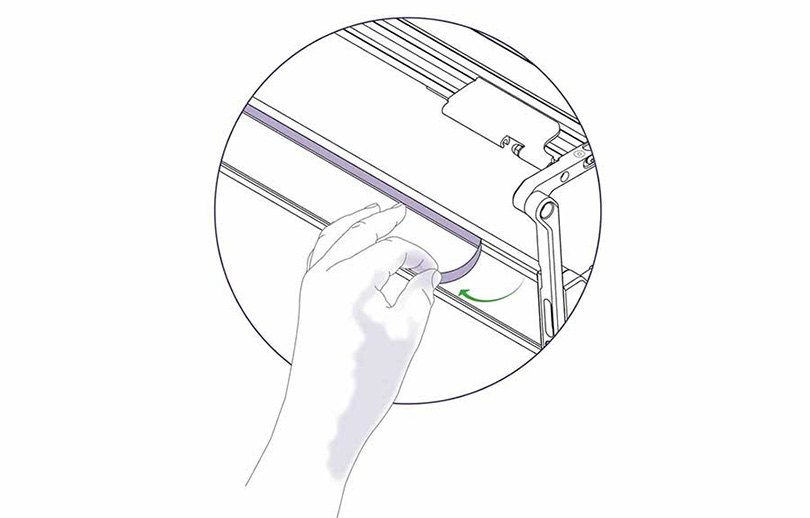

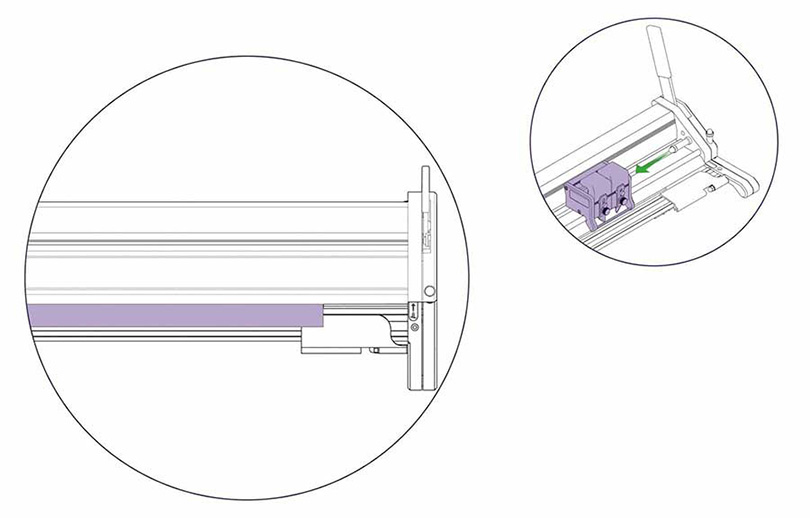

The cutting strip is removed by sliding it to the right, to keep the orientation of the strip correct the left hand end should remain on the left once turned over.

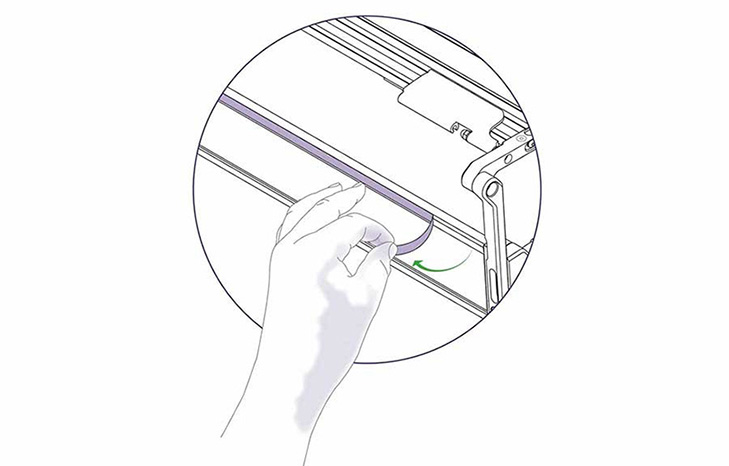

There is a small adhesive patch under the left hand end of the strip to prevent it sliding in use, lift up the strip by sliding a flat edge under the left hand end of the strip and it should then slide to the right. A wide bladed flat screwdriver can be used to help push the strip.

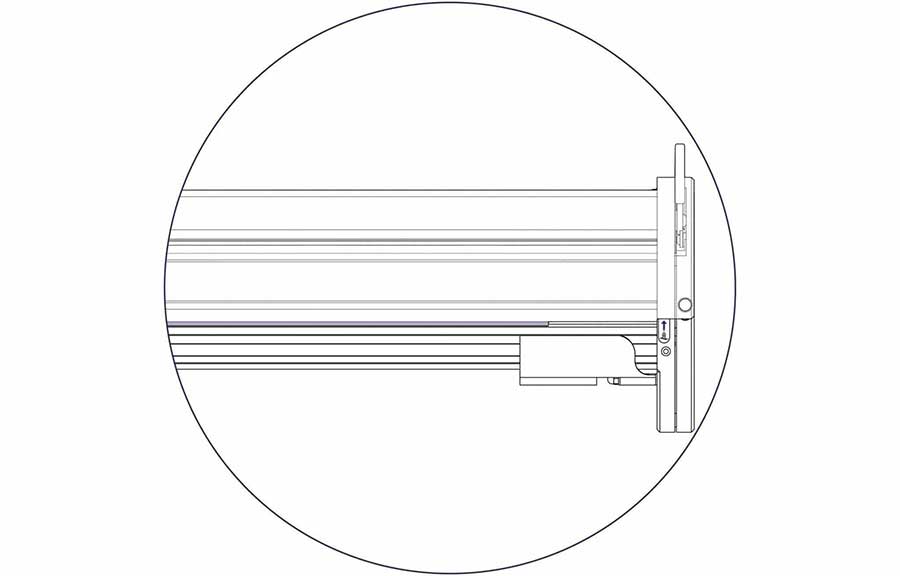

Turn over and re-insert the cutting strip so that the smooth surface is now facing upwards and what was the left hand end goes in first. Push it in nearly all the way, again use a flat edge under the left hand end to raise the strip above the adhesive patch, when in position press the strip onto the patch to prevent it sliding.

Should the patch have lost its stickiness, peel it off and replace with a small piece of double-sided adhesive tape.

Once the strip has been fully used on both sides a new strip will be required, these are available from your dealer. Keencut part code EVOTCS

Tip: Order replacement strips (or check stock) whenever turning a strip over.

When using your SmartFold, the sightline strip may become scored or damaged.

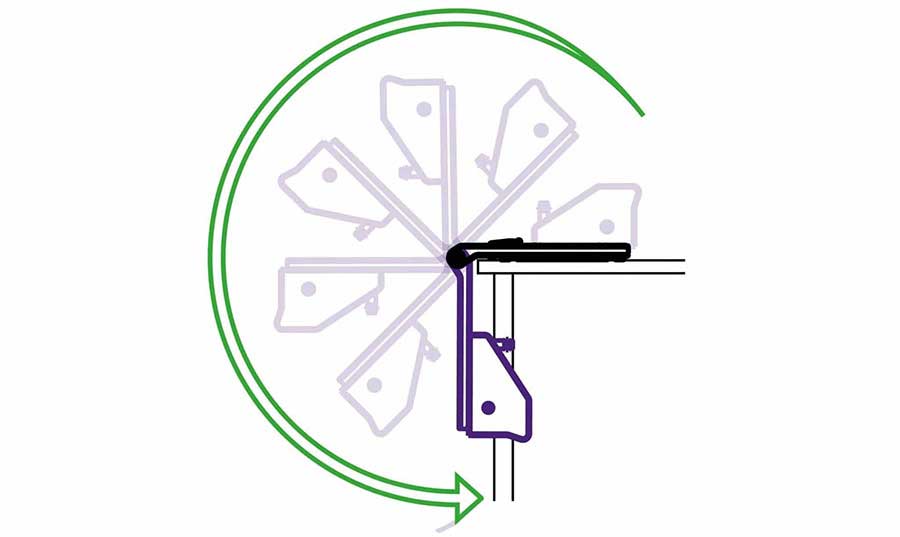

To change the sightline strip, first grip the cutter bar firmly, lift carefully and swing over the edge of the bench, bring gently to a stop when vertical.

| Be careful when lifting |

You will see the sightline strip on the underside of the cutter bar.

Remove the damaged sightline strip making sure that all residue from the adhesive tape is removed.

Your new sightline strip will have a protective backing on the double sided tape found on the underside of the part. Remove this backing.

Apply the sightline strip in stages from left to right, ensuring that no wrinkles or bubbles form under the tape.

Once you fold over your SmartFold, you will notice the sightline strip is larger than it needs to be. Use the Double Graphik tool head to gently cut the sightline strip.

Tip: it is recommended to do this in 3 passes to ensure that the line cut by the blade is as straight as possible.

Once you have removed the excess, your sightline strip will be configured to your machine giving 0.2mm of accuracy.

Tip: Order replacement strips (or check stock) when you notice any damage.

When using the Fabric tool head with the purple plastic cutting strip, it will become scored and require replacing. Adjustment of the cutting pressure to keep it to a minimum for the fabric being cut will help to extend the life of the strip. Check you have used all four cutting tracks on the strip before proceeding.

Carefully fold the cutter bar over to reveal the base plate. This may require 2 people.

| Be careful when lifting |

Both sides of the cutting strip can be used, it is important the strip is turned over in the correct orientation. The four tracks are offset to one side so when the strip is turned over correctly the new set of four tracks do not align with the originals.

The cutting strip is removed by sliding it to the right, to keep the orientation of the strip correct the left hand end should remain on the left once turned over.

There is a small adhesive patch under the left hand end of the strip to prevent it sliding in use, lift up the strip by sliding a flat edge under the left hand end of the strip and it should then slide to the right. A wide bladed flat screwdriver can be used to help push the strip.

Turn over and re-insert the cutting strip so that the smooth surface is now facing upwards and what was the left hand end goes in first. Push it in nearly all the way, again use a flat edge under the left hand end to raise the strip above the adhesive patch, when in position press the strip onto the patch to prevent it sliding.

Should the patch have lost its stickiness, peel it off and replace with a small piece of double-sided adhesive tape.