Evolution3 FreeHand User Guide – Care and maintenance

Use a vacuum cleaner to remove any dust and smaller debris.

Frequency: daily as required

Moisten a cloth with diluted detergent to wipe down the cutter bar and base plate, dry with a cloth.

Frequency: weekly

DO NOT use solvents or aggressive cleaning products.

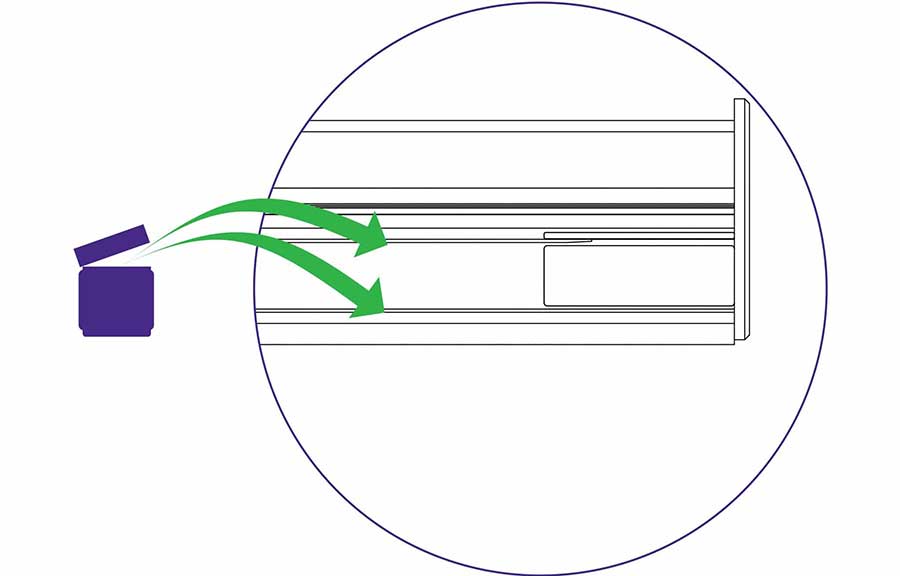

Put a small amount of petroleum jelly (Vaseline) on the scouring surface of a dish washing sponge and rub it up and down the two tracks. Wipe clean any surplus with a dry cloth.

Frequency:

Light use – monthly

Heavy use – weekly

When using your FreeHand, the sightline strip may become scored or damaged.

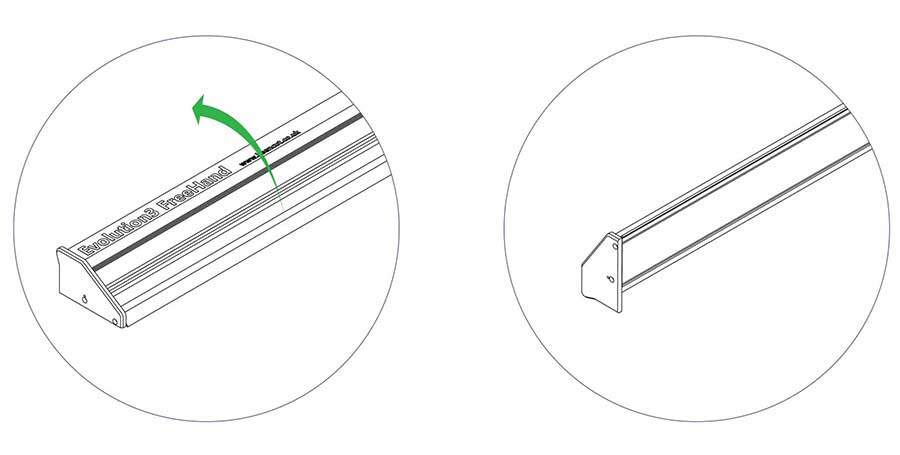

Remove any tool heads.

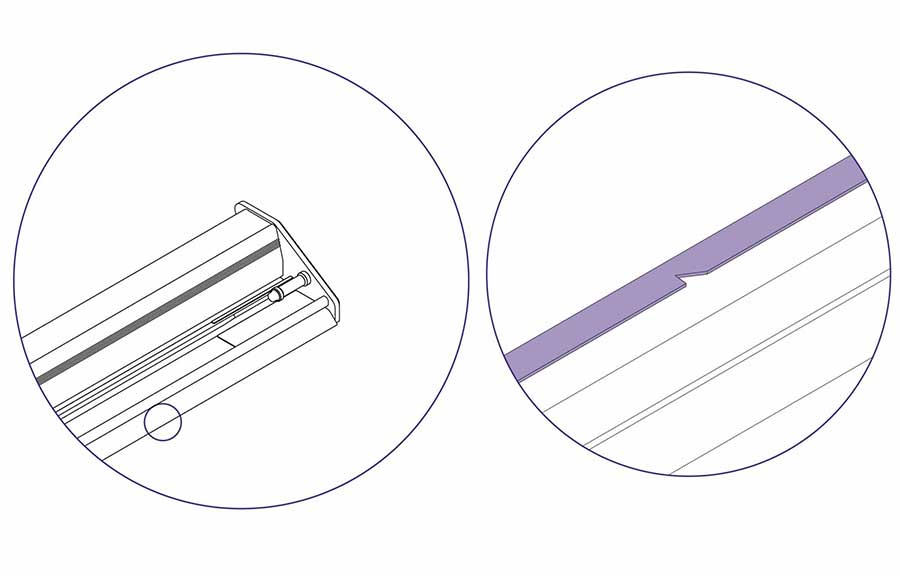

Turn over the FreeHand so that the underside is visible.

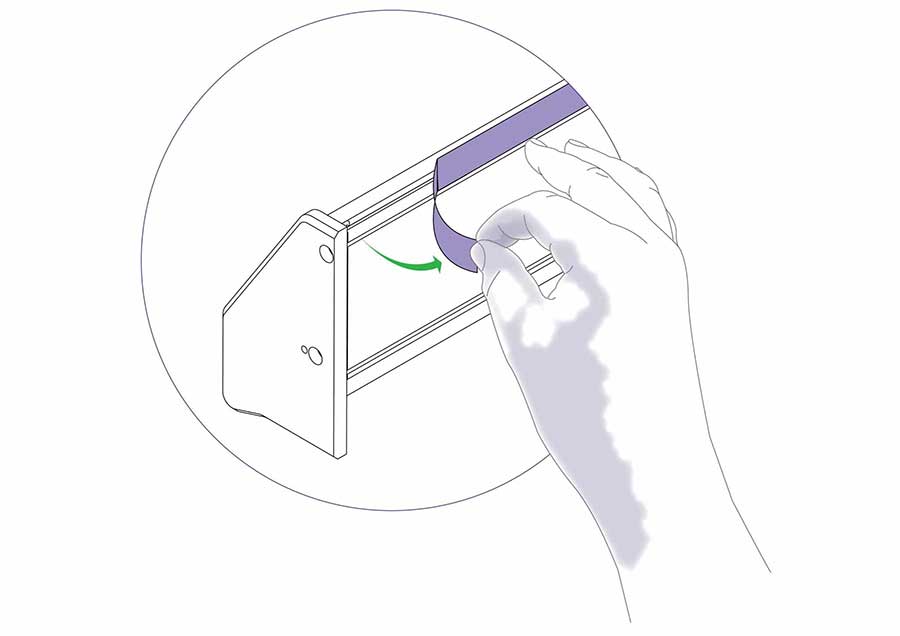

Remove the damaged sightline strip making sure that all residue from the adhesive tape is removed.

NOTE: If you are struggling to remove any adhesive residue, lightly use methylated spirit on a paper towel or cloth.

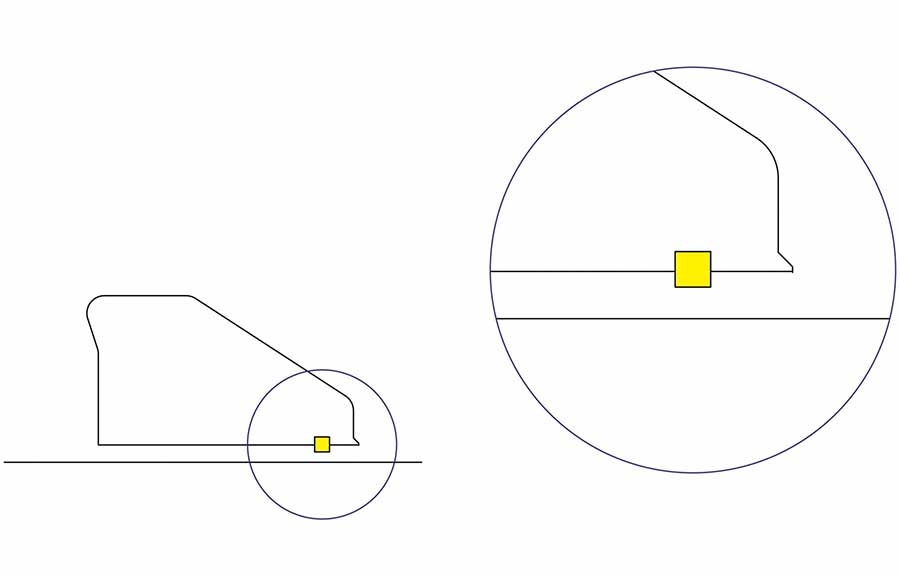

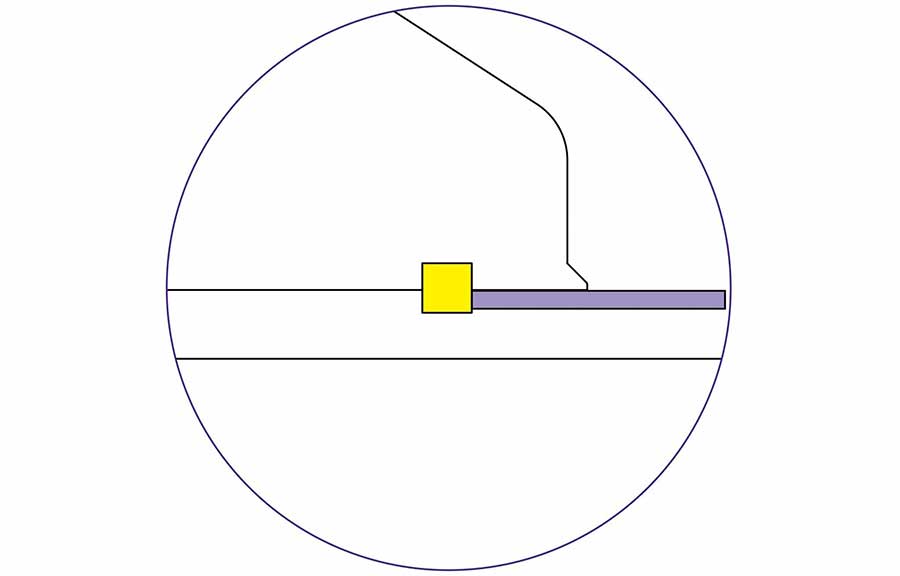

There is a yellow silicone grip strip fixed to the underside of the cutter bar, use this to help align the back edge of the replacement sightline strip.

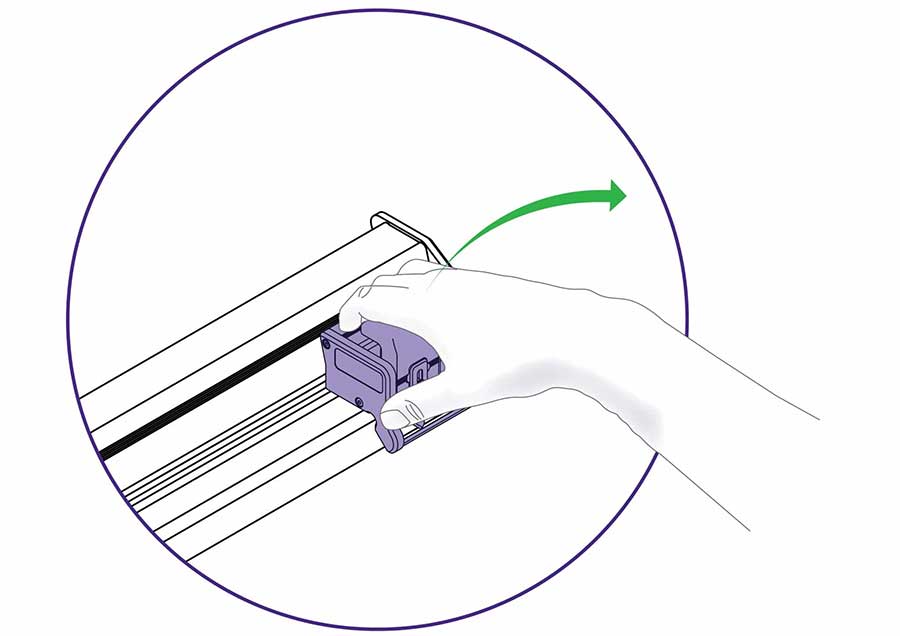

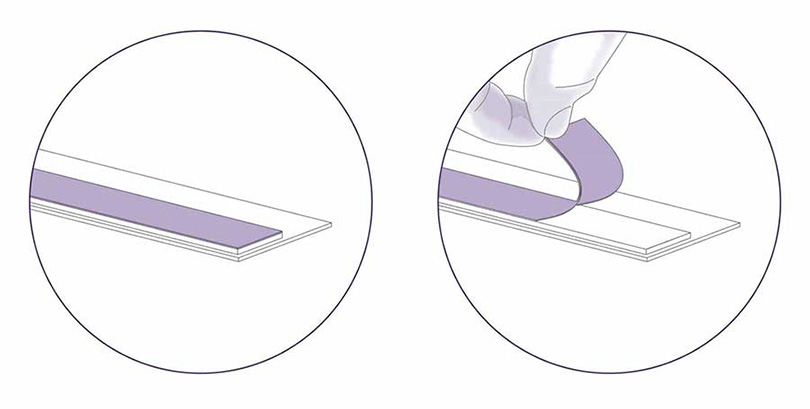

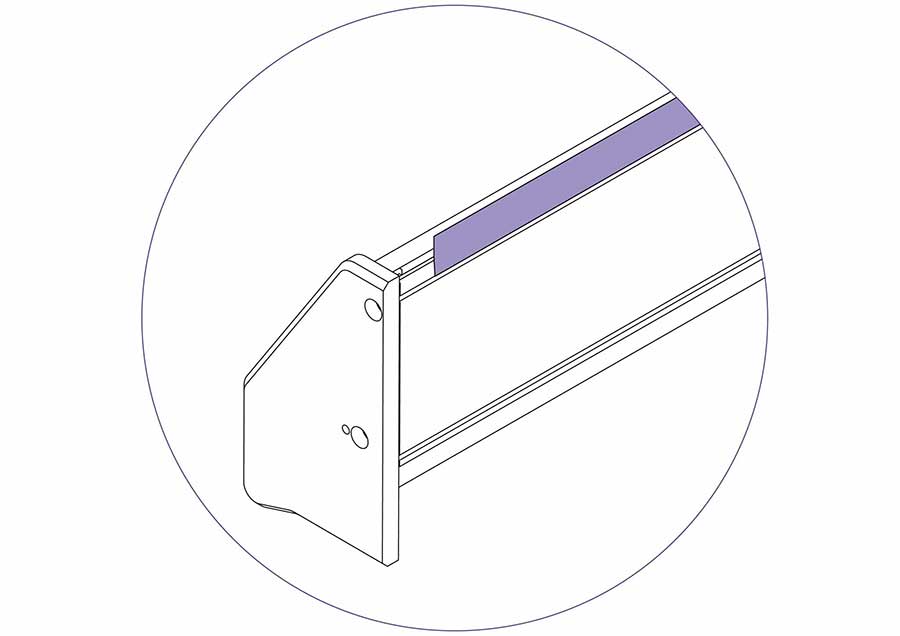

Remove the first 20cm – 8″ of the protective backing from the new sightline strip.

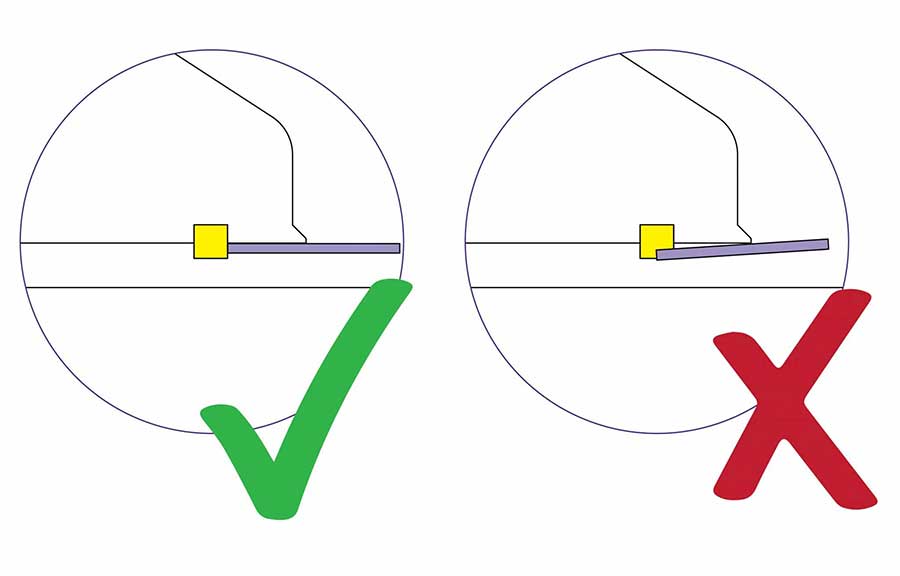

Apply the sightline strip in stages from one end of the cutter bar to the other using the yellow silicone grip as your guide; the back edge of the sightline strip should be touching the front edge of the silicone grip.

TIP: Remove the protective backing from the double-sided tape in stages to prevent complications during application.

Ensure that the sightline strip does not overlap the silicone grip as this will affect the clamping of the cutter bar.

Apply pressure to the underside of the sightline strip to ensure the sightline strip is secured in position.

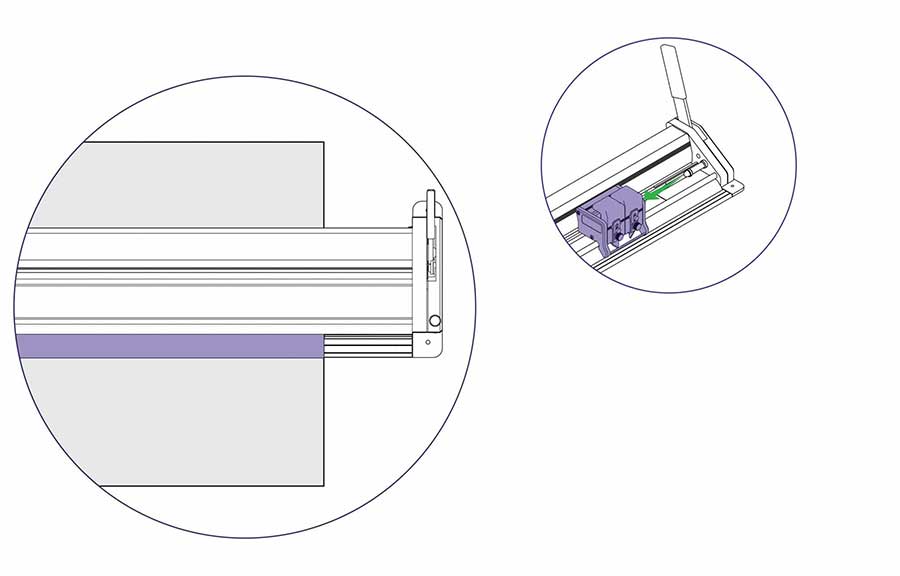

The sightline strip is wider than it needs to be and requires trimming to suit cutting line of the machine.

Use the Double Graphik tool head to gently cut through the sightline strip in 3 to 4 passes. This will ensure the sightline strip is not distorted and indicates the blades line of cut accurately.

TIP: Order replacement strips (or check stock) whenever you change the strip to save running out.