Evolution3 SmartFold User Guide – Rocker tool head

The Rocker tool head has been especially designed to give perfect comfort for all day, every day, cutting. The tool head fits the curve of your hand, allowing you to cut denser materials with ease.

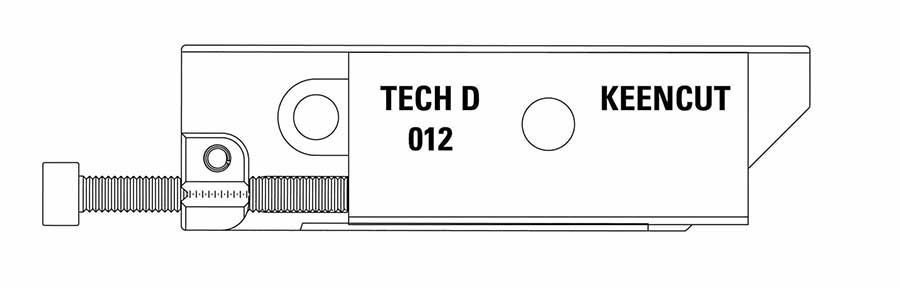

The Rocker head accepts the Medium Duty blade and the specialist Tech D012 blade. This will allow you cut Aluminium Composite Panels (ACP) alongside standard materials.

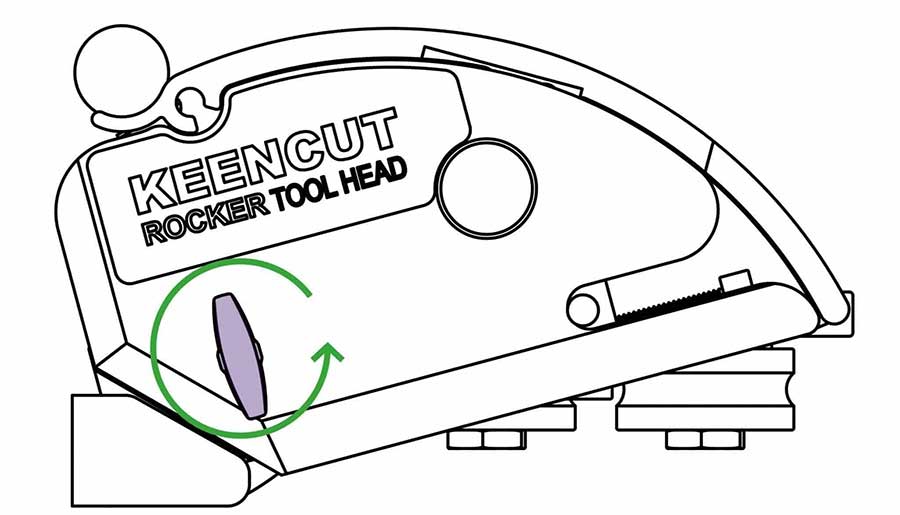

To change the blade, loosen the blade clamping knob.

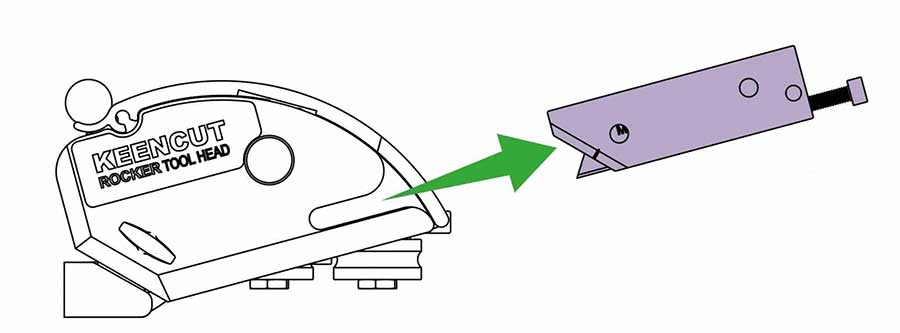

Remove the magnetic cartridge from the Rocker head.

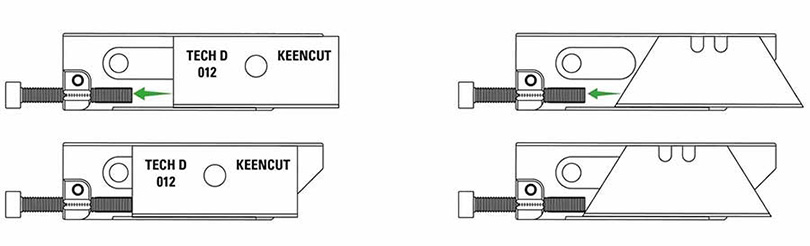

Place the blade between the two guides, the magnet will hold it in place, and slide it back to touch the blade depth screw. The blade depth screw can be adjusted to set the blade correctly for the thickness of material to be cut.

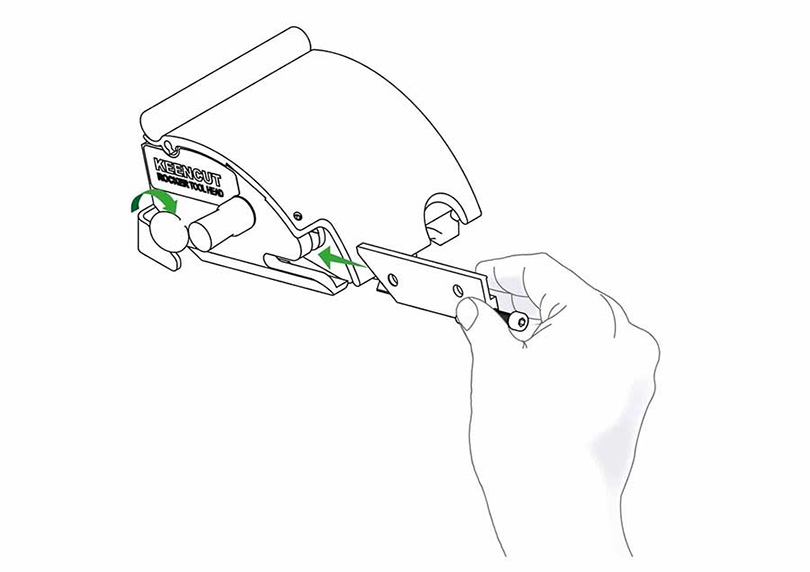

Place the blade cartridge back into the cutting head, press on the end of the blade depth screw to ensure it is located fully in its slot and tighten the blade clamping knob.

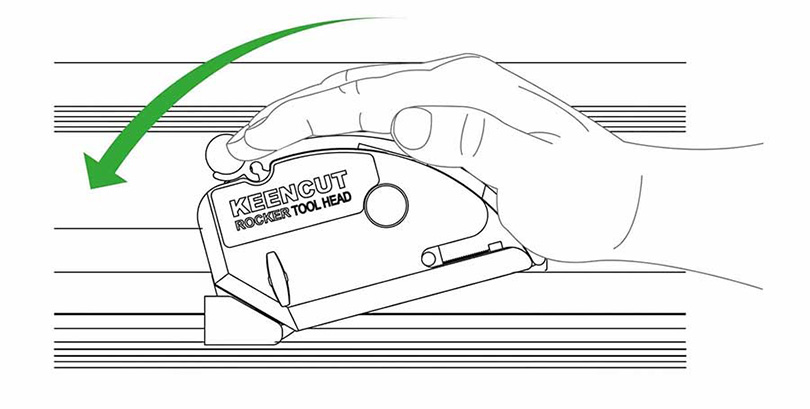

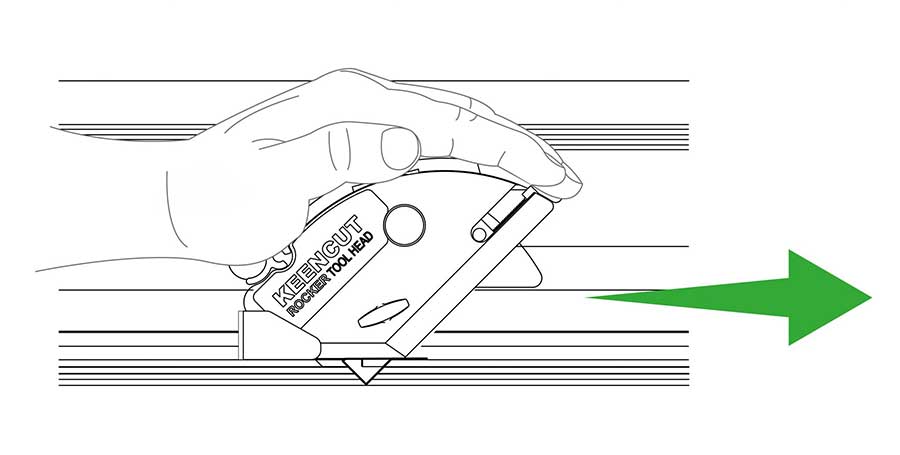

When cutting thinner / less dense materials, ensure the blade depth is adjusted so only the tip of the blade is going through the material. Place your hand on the Rocker tool head as shown and rock it forward to engage the blade.

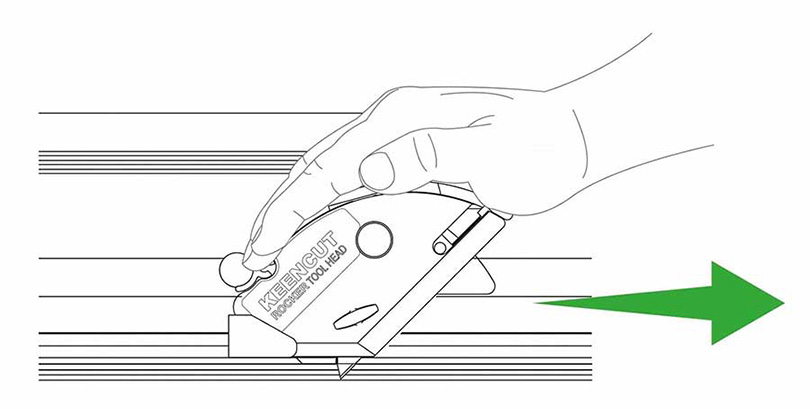

With the blade engaged, pull the Rocker tool head in one continuous motion along the material to achieve the best results.

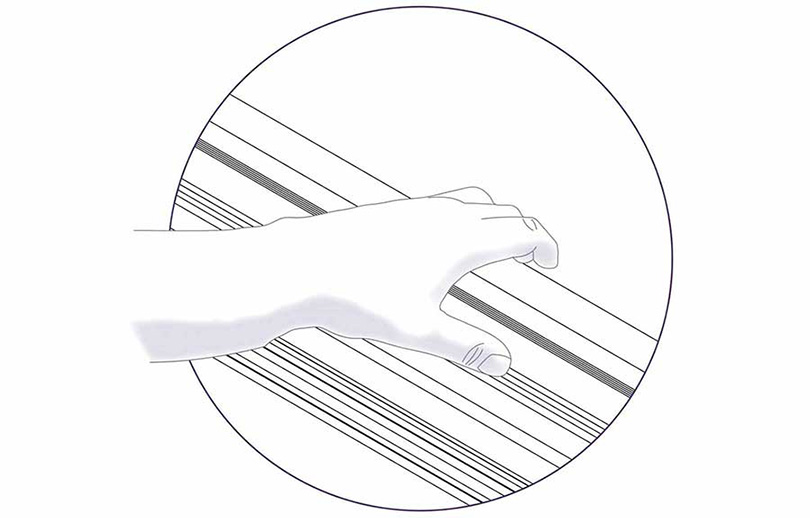

If the material creases at the beginning of the cut use the index finger on your other hand to pinch the material onto the base plate and hold it in place whilst the blade enters the material.

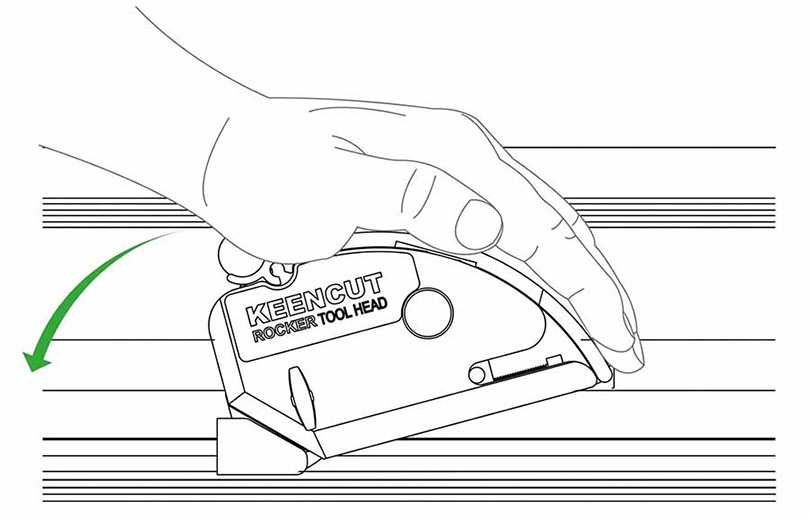

When cutting thicker / more dense materials, ensure the blade depth is adjusted so the blade tip cuts 1-2mm (1⁄16) through the material. Place your hand on the Rocker tool head as shown, press down with your palm to engage the blade.

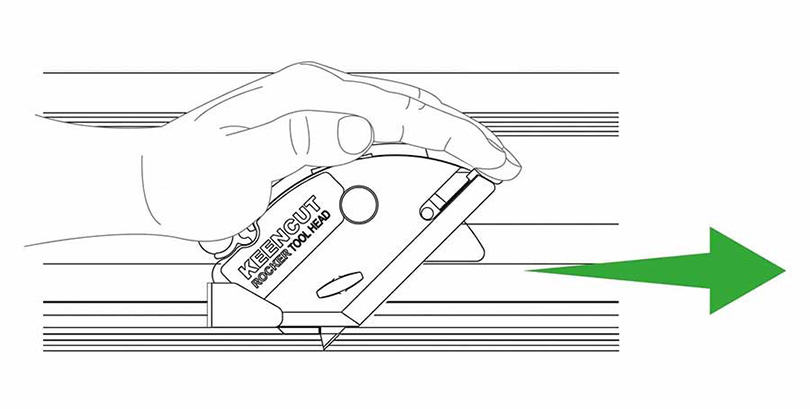

Push the Rocker tool head slowly through the material.

Extra effort can be applied by holding the grip area on the top of the cutter bar with your other hand and using the strength across your shoulders to push. Thicker materials can be cut in several passes.

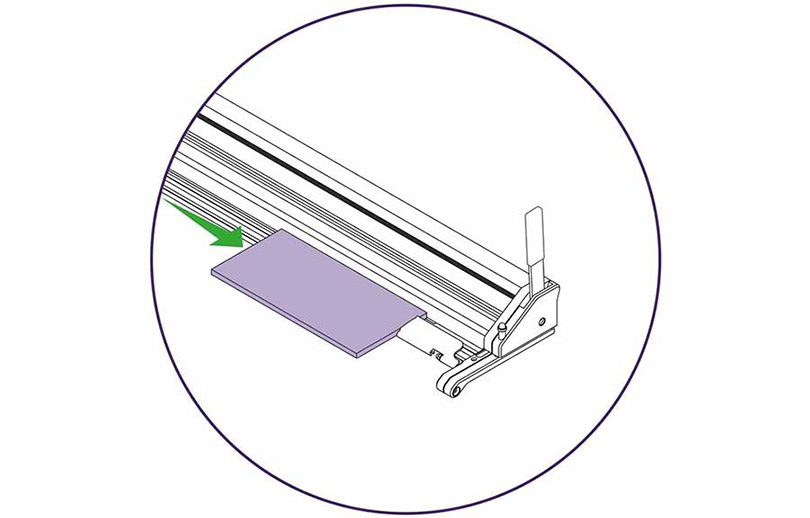

The material should be in contact with the material stop to prevent it moving when cutting.

Use the Tech D012 blade and set the depth so the tip passes through the ACP by 1-2mm (1⁄16”).

Use the push technique to cut though the ACP, it usually takes 5-6 passes of the blade to cut all the way through and will require an amount of effort.

The finish should be clean but the edges may be sharp and require finishing with a file.

Alternatively, some ACP’s will snap once the top foil has been cut, bend back and forth a few times to break the bottom foil then clean the edges with a file.

The Rocker tool head has been especially designed to give perfect comfort for all day, every day, cutting. The tool head fits the curve of your hand, allowing you to cut denser materials with ease.

The Rocker head accepts the Medium Duty blade and the specialist Tech D012 blade. This will allow you cut Aluminium Composite Panels (ACP) alongside standard materials.

Place the blade between the two guides, the magnet will hold it in place, and slide it back to touch the blade depth screw. The blade depth screw can be adjusted to set the blade correctly for the thickness of material to be cut.

When cutting thinner / less dense materials, ensure the blade depth is adjusted so only the tip of the blade is going through the material. Place your hand on the Rocker tool head as shown and rock it forward to engage the blade.

With the blade engaged, pull the Rocker tool head in one continuous motion along the material to achieve the best results.

If the material creases at the beginning of the cut use the index finger on your other hand to pinch the material onto the base plate and hold it in place whilst the blade enters the material.

When cutting thicker / more dense materials, ensure the blade depth is adjusted so the blade tip cuts 1-2mm (1⁄16) through the material. Place your hand on the Rocker tool head as shown, press down with your palm to engage the blade.

Extra effort can be applied by holding the grip area on the top of the cutter bar with your other hand and using the strength across your shoulders to push. Thicker materials can be cut in several passes.