Evolution3 FreeHand Installation Manual

How to use this guide

Scroll down to view the guide.

You can expand and collapse sections using the + and – icons.

The images in this manual are expandable. Click/tap on them to enlarge.

View PDF version >

Other support resources

Register your cutter to activate your guarantee >

Visit Keencut support centre >

Visit user forum >

Contact Keencut >

You will need approximately 1 hour to install and calibrate your cutter

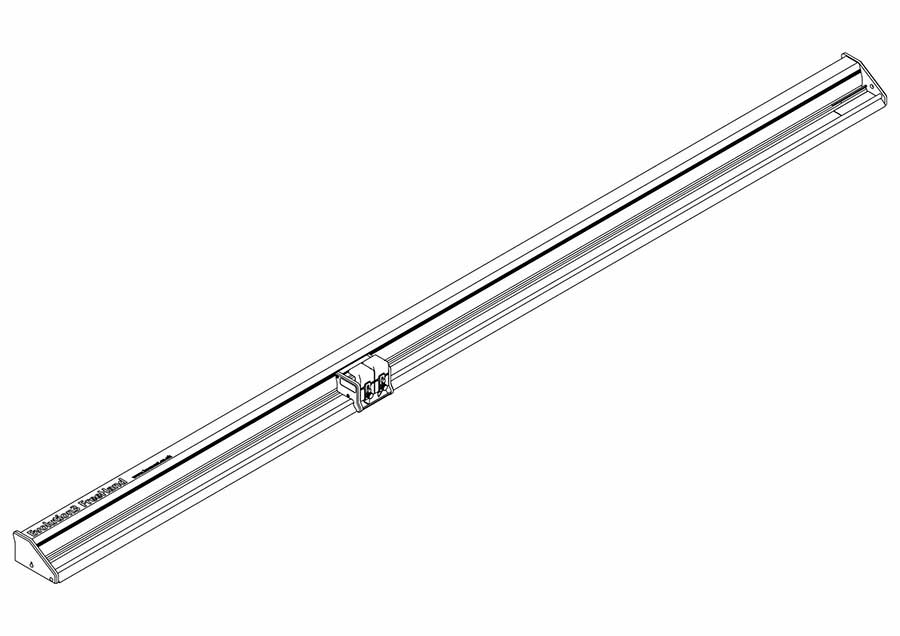

The Evolution3 FreeHand comes in 5 different sizes ranging from 1.1m (44″) to 3.1m (124″)(cutting length) in 0.5m (20″) increments. Each machine is fitted with a Double Graphik blade cutting head.

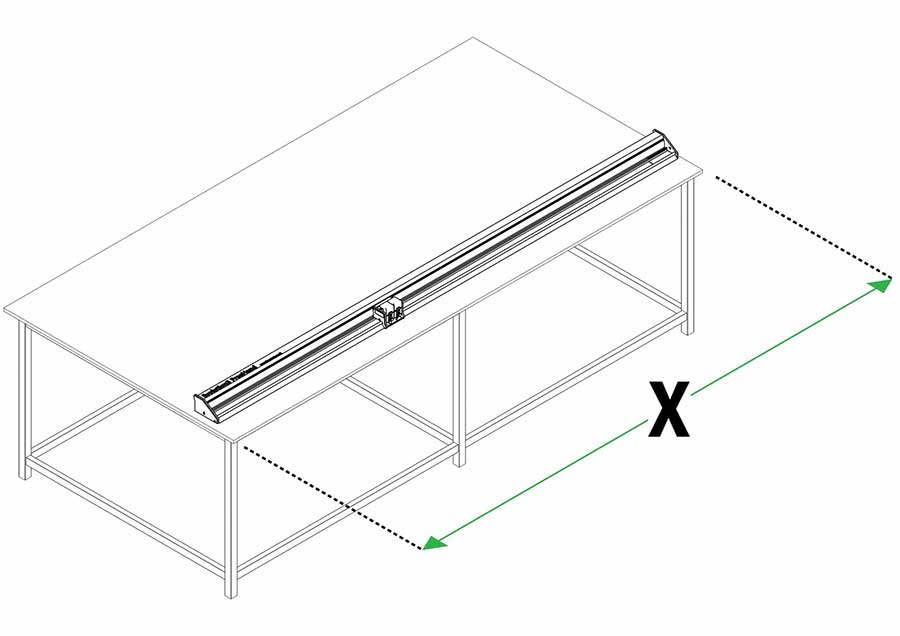

The width of the work surface needs to be 40cm (16″) wider than the cut length of the FreeHand.

Metric example: E3FH260 260cm + 40cm = 300cm

Imperial example: E3FH104 104” + 16” = 118”

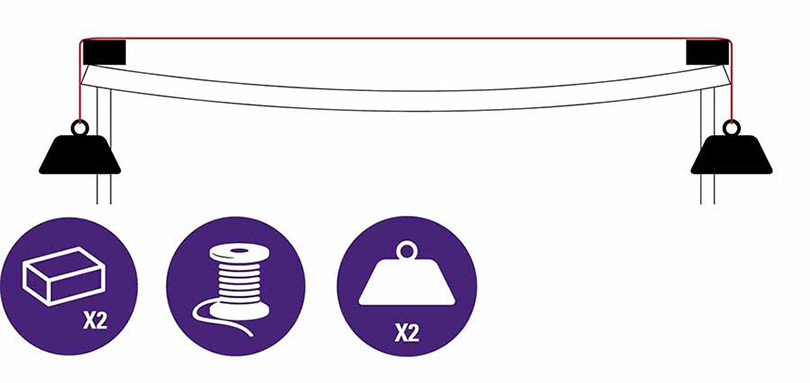

Check the flatness of the worktop by stretching a thin piece of strong thread between two blocks of the same height approximately over the area the cutter is to be used.

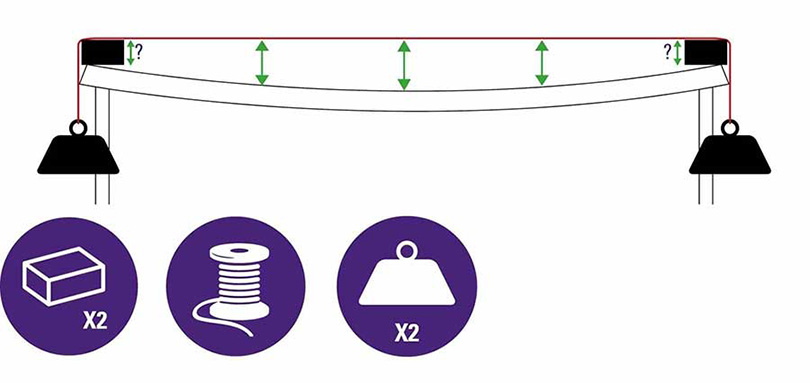

Measure the highest and lowest part of the worktop under the thread, the difference between the two measurements should ideally be no more than 1mm (1/16″). If it is greater it will be necessary to adjust the surface flatness with a new top or by using spacing pieces between the worktop and bench framework.

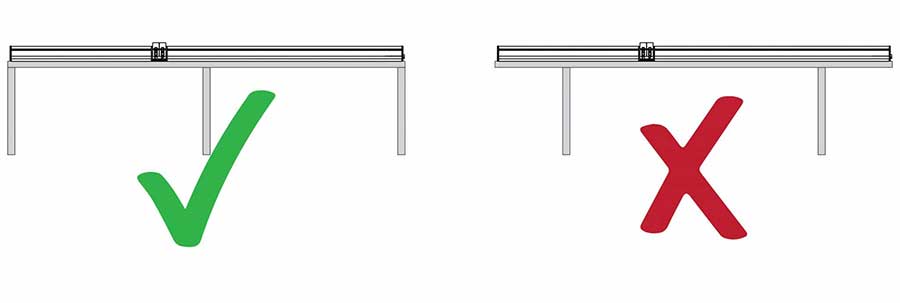

The work surface must be stable with a robust framework below and good support (no flexing) particularly in the area under the two ends of the cutter.

Both ends of the cutter should be fully supported and not overhanging the work surface.

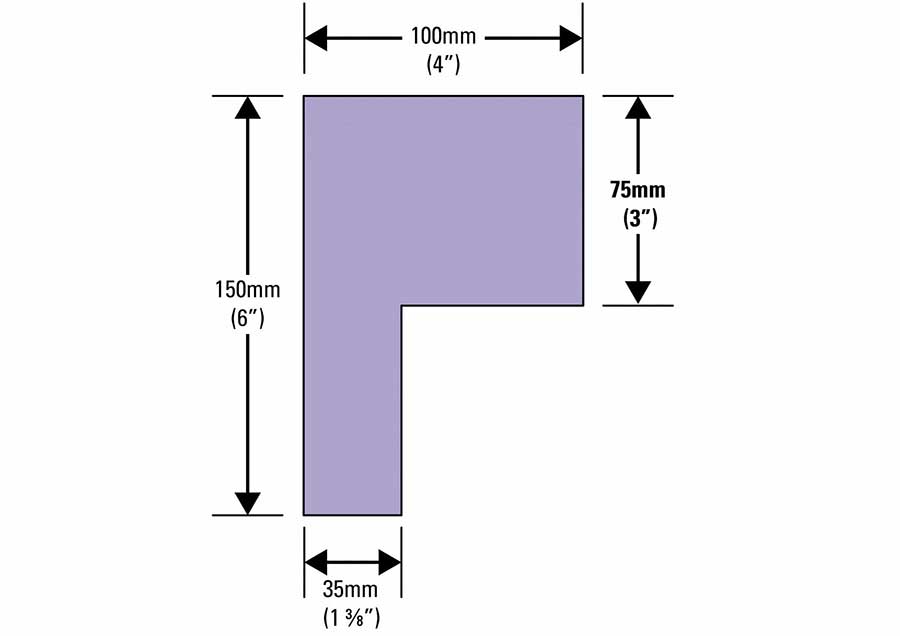

Create two ‘L’ shape blocks from 25mm (1″) wood, MDF or plastic approximately to the following dimensions. These will be used as location guides for your FreeHand and a means of holding it above the worksurface whilst you have both hands free to place the material to be cut.

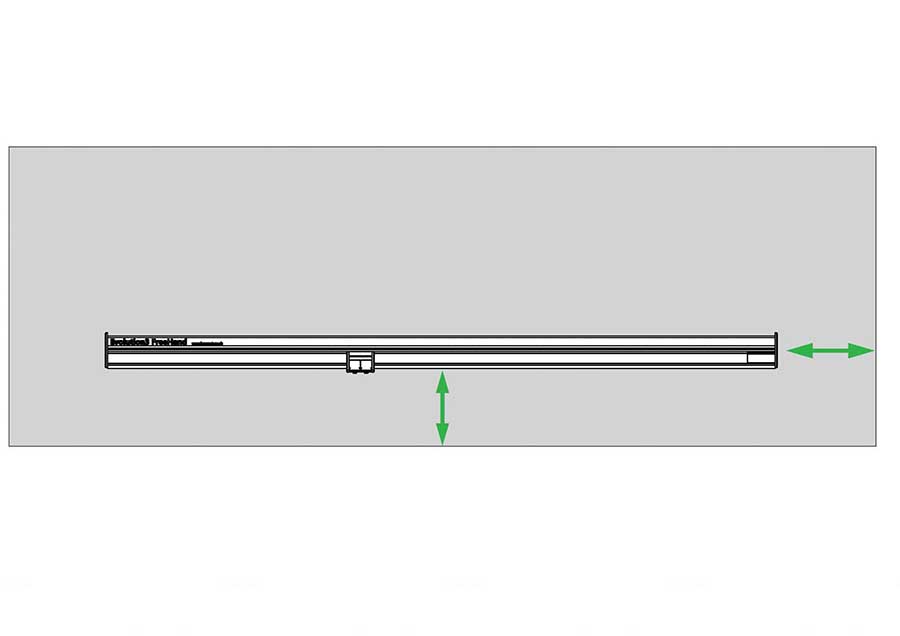

Place the FreeHand in its flat working position on the workbench. Make sure that it is in alignment with the edge of the work bench and a comfortable distance in from the edge of your bench.

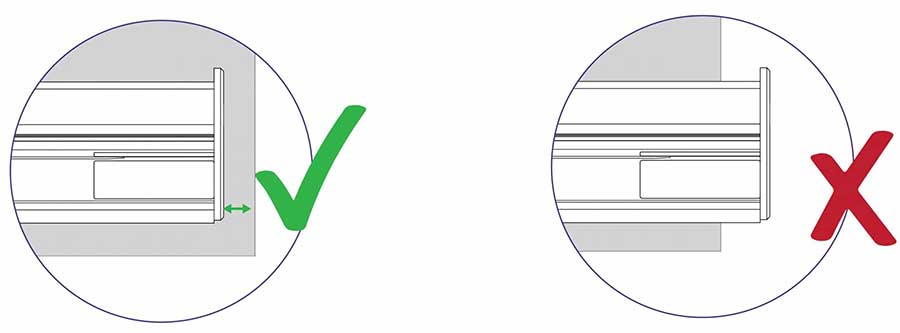

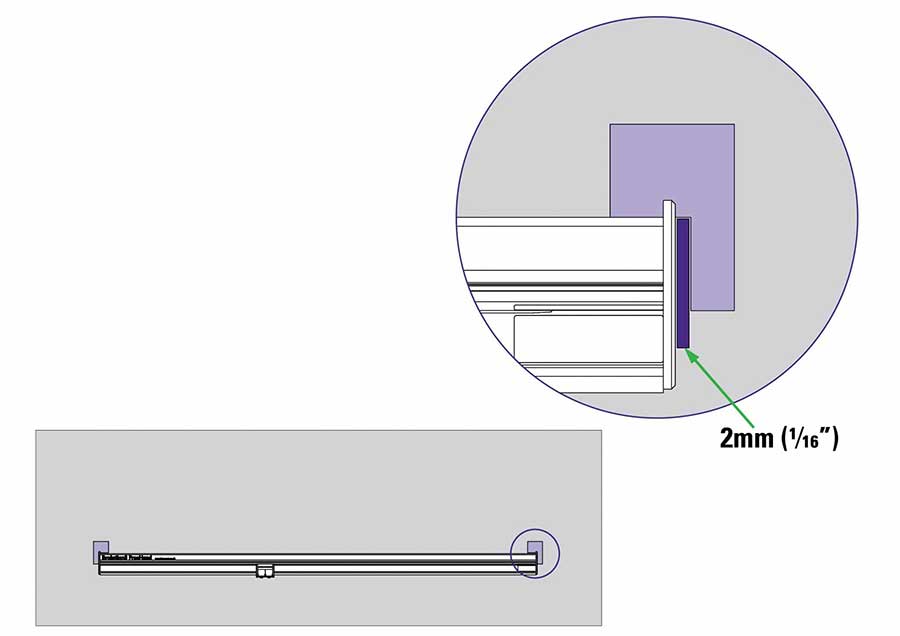

Position the two blocks as shown with a 1-2mm (1/16”) spacer between one end of the FreeHand and the inside edge of the adjacent block. Fix the blocks to the work surface. Ensure the FreeHand can be lifted and moved with ease and is not rubbing against the blocks.

When placed within the blocks the FreeHand is in a fixed cutting position. Either:

1) Make a cutting groove in the work surface:

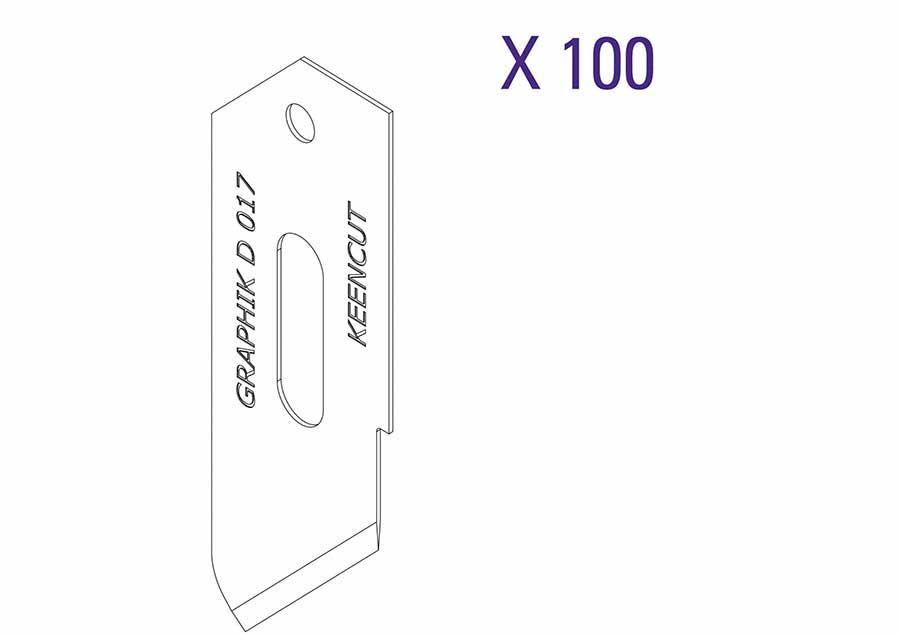

A mark can be made on the table surface using Graphik blade and this used as a guide to cut a groove in the worksurface with a power saw. A cutting mat will be required should the Fabric Tool head be used.

2) Line the table surface with a cutting mat, PVC foamboard or similar:

This will need to be fixed in place either by screwing the two blocks through it or by using double sided adhesive tape. The blade tip should always run in the original cutline when the FreeHand is positioned within the blocks.

Multiple workstations can be created and the FreeHand shared between them.

Registering your FreeHand machine will activate your 5 year guarantee.

See the Evolution3 FreeHand User Guide for advice on cutting techniques, using the different cutting heads and care and maintenance of your machine.