Replacing the glass wheel on an Excalibur 5000

The following instructions show how to fit the a new glass cutting wheel and ensure its correct rotation.

3. Check wheel rotation and pressure of wheel

Try rotating the wheel, if it does so freely try scoring some glass and if necessary adjust the pressure on the wheel by following these instructions > The aim is a light continuous score line that does not appear ‘white’ and have any splinters of glass chipping out of it.

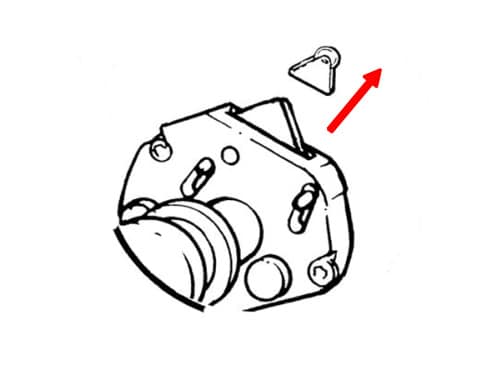

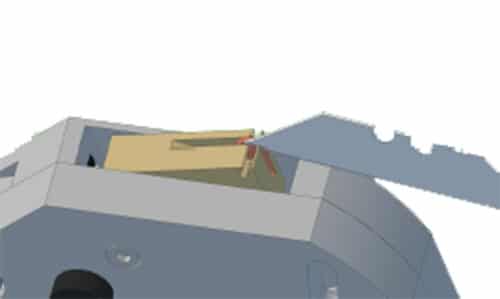

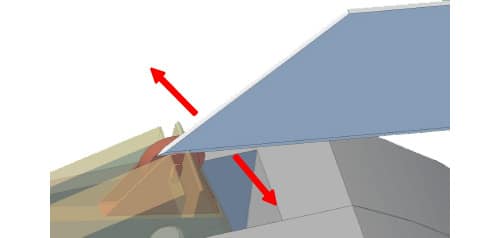

If the wheel does not rotate freely place some MDF in the machine and run the wheel up and down using light finger pressure. The wheel can be also be eased by carefully placing a blade between the side of the wheel and the edge of the triangular clip and lightly rocking the blade to free any burrs or debris from between the wheel and clip. Do this on both sides of the wheel. When the wheel turns freely, adjust the pressure if necessary as previous using these instructions>