Use this guide to troubleshoot an issue with your SteelTrak clamp

Before you start

Before starting any work, check that the machine is firmly fixed to the wall or freestanding leg.

Select which of the four situations below best matches your clamp issue, then scroll down to the relevant section. If you are not sure what your issue is, please start at the top and work through each section to diagnose.

- Clamp not closing fully or out of alignment

- Clamp not closing fully in the middle

- Clamp pressure too low

- Clamp is not working at all – when pressing the clamp handle the clamp bar does not move

1. Clamp not closing fully or out of alignment

Clamp will not fully close

If the clamp will not fully close, the first thing to check is the clamp bar is correctly positioned and not moved off its internal guides. This solves the issue 90% of the time. Check my clamp bar is in place > If your clamp is still not closing, there may be a part worn in the clamp housing or within the clamp itself. Please refer to step number 3: Clamp pressure too low.

Clamp does not close fully along the length

If your clamp is partially out of alignment either at the top or bottom, it may require adjustment to re-align. Follow our guide on How to adjust the SteelTrak clamp alignment > If you are stilll finding the clamp is not fully closing in the middle please refer to step number 2: Clamp not fully closing in the middle.

2. Clamp not closing fully in the middle

Due to aluminium tolerances, there may be a small gap between the middle of the clamp and the spine when it is closed and touching at the top and the bottom. The design of the clamping system takes this into account and will not affect its clamping ability. If the gap is more than 1-2 mm check the following:

- Check the clamp bar is positioned correctly and not moved of its internal guides. Check my clamp bar is in place >

- Measure the gap between spine and slideway and contact Keencut if the gap is more than 2mm (1/16″). How to measure the gap between spine and slideway on a SteelTrak clamp bar >

3. Clamp pressure too low

There could be a number of reasons the clamp seems to have reduced pressure compared to normal. Follow the steps below to find out what could be causing this in your machine.

- Adjust clamp pressure (as in manual – section 7.12) – Download the manual > or check out the short guide >

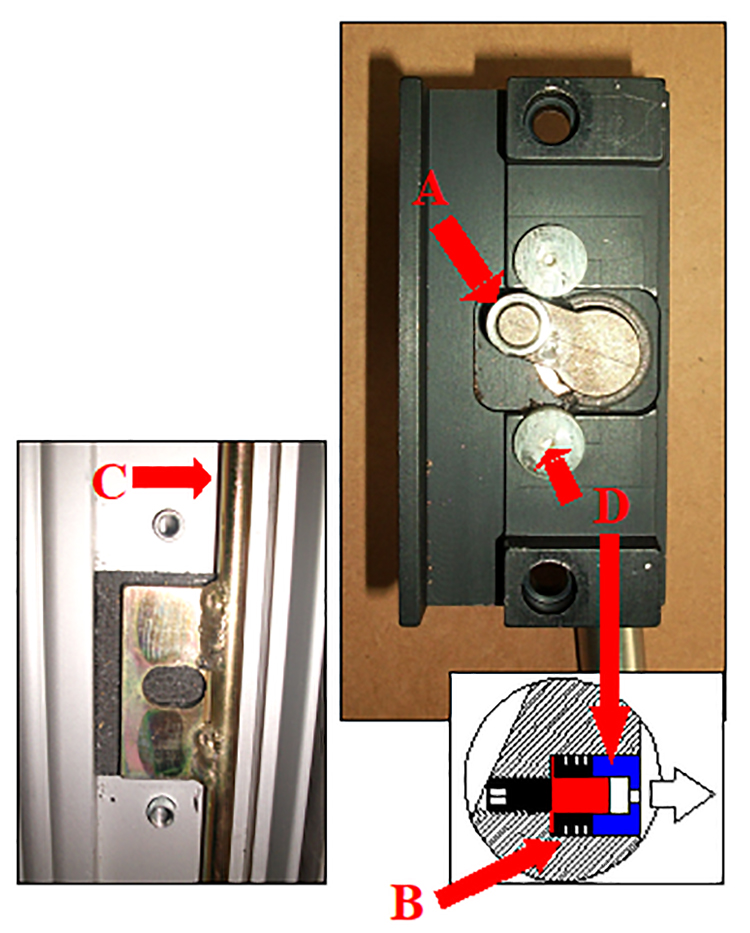

- Over time, parts inside the handle can become worn and less effective. Check inside the handle assembly to see if you can identify if this is the cause of your reduced clamp pressure. Inside the SteelTrak clamp housing assembly >

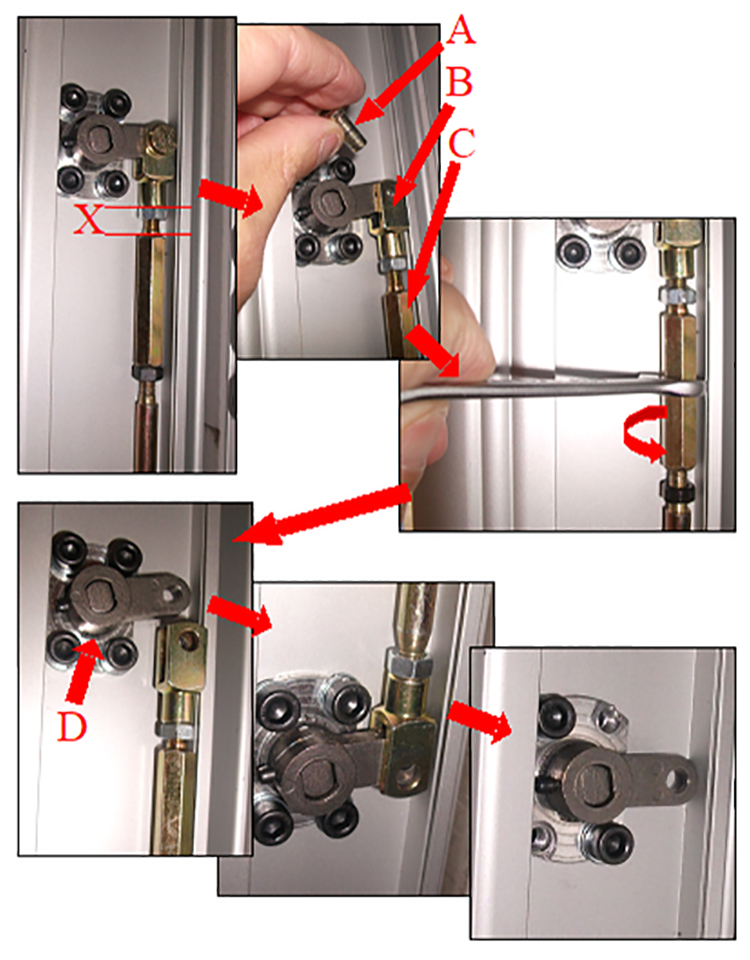

- As with the handle, over time the push rod assembly inside the spine can become worn and less effective. Check the SteelTrak clamp rod assembly >

4. Clamp is not working at all - when pressing the clamp handle the clamp bar does not move

- Over time, parts inside the handle can become worn and require maintenance. Check inside the handle assembly to see if you can identify if this is why your clamp is not moving. Inside the SteelTrak clamp housing assembly >

- As with the handle, over time the push rod assembly inside the spine can become worn and may need attention. Check the SteelTrak clamp rod assembly >