How to measure the gap between the slideway and spine on a SteelTrak

Before you start

Before starting any work, check that the machine is firmly fixed to the wall or freestanding leg and that you have the following equipment:

Piece of aluminium composite panel, e.g. Dibond – approximately A4 sized

Sharp hand knife

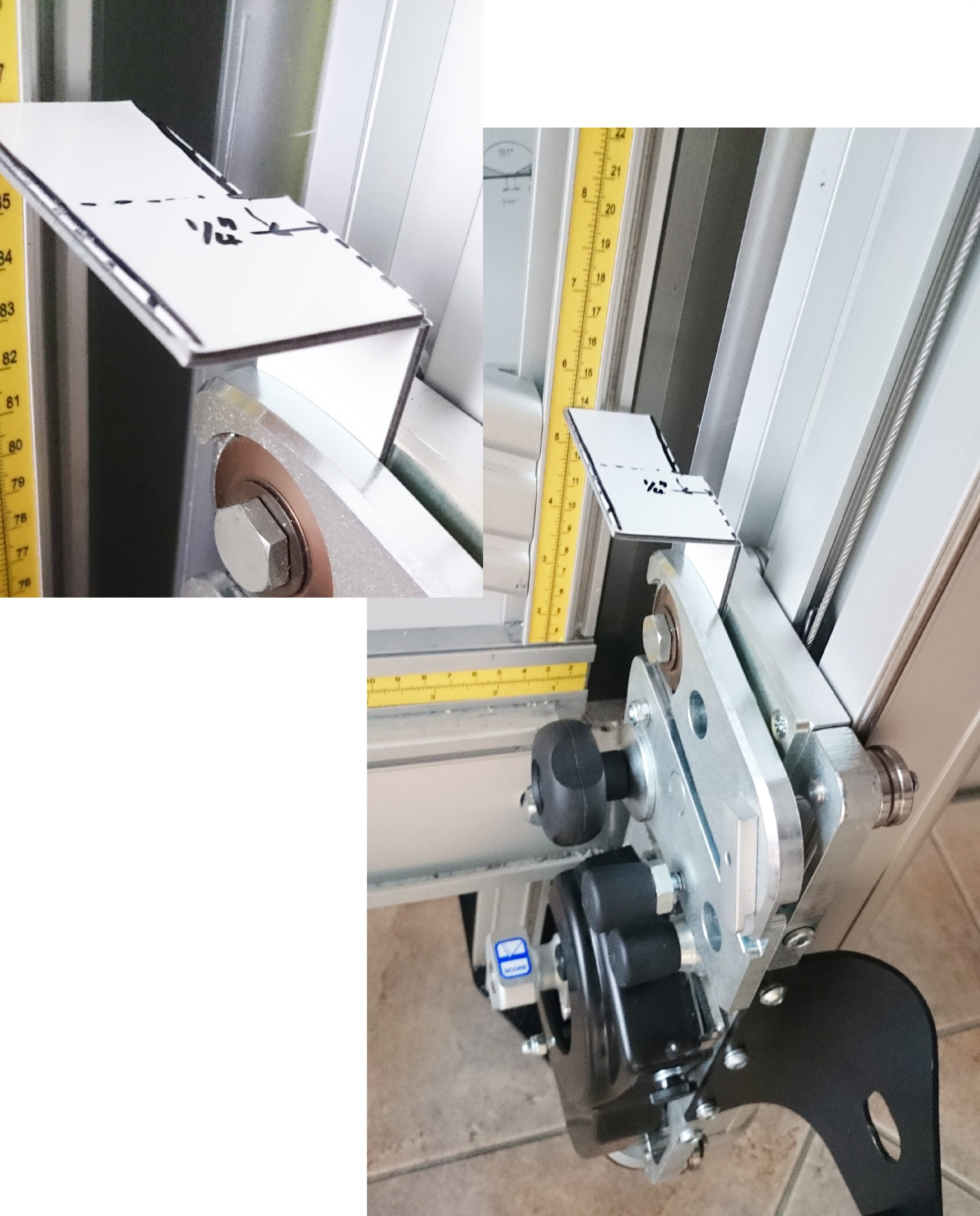

Clamp the aluminium composite panel in position

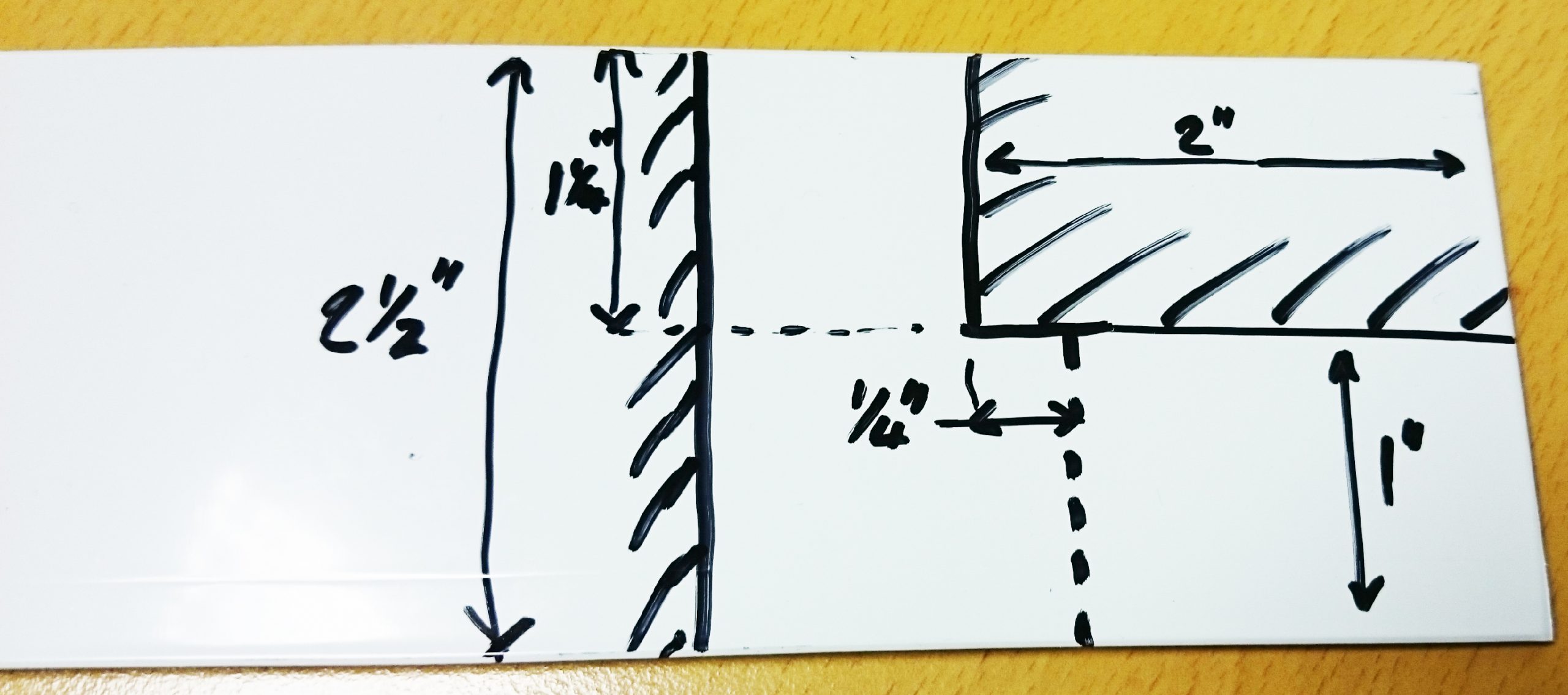

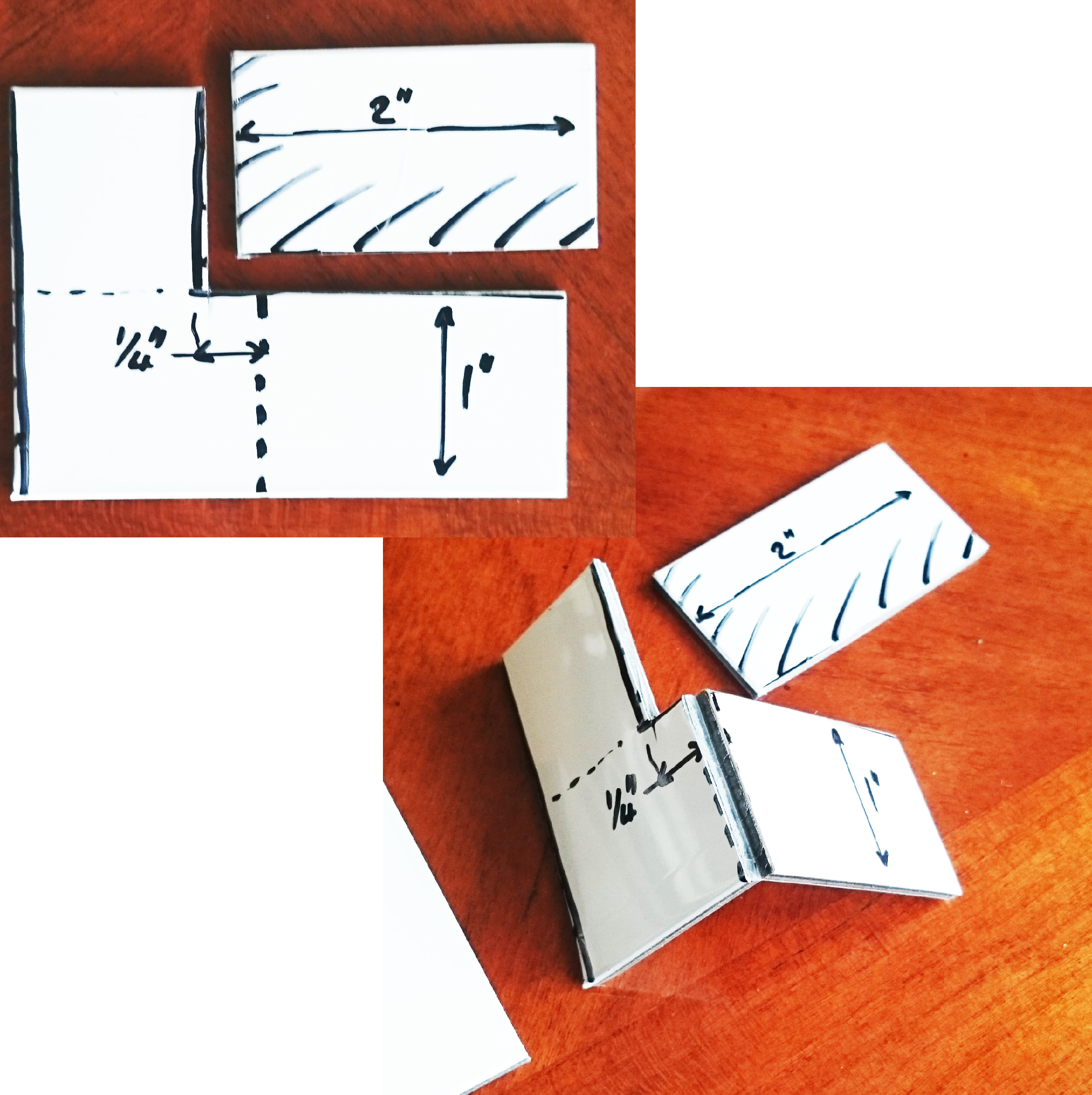

With the cutting head at the bottom of the machine, clamp the aluminium composite panel behind the twin wheel cutter, as shown. Position the board so there is a small 2mm (1/16”) gap between the edge of the panel and the ‘spine’ of the machine, shown by the red arrow.