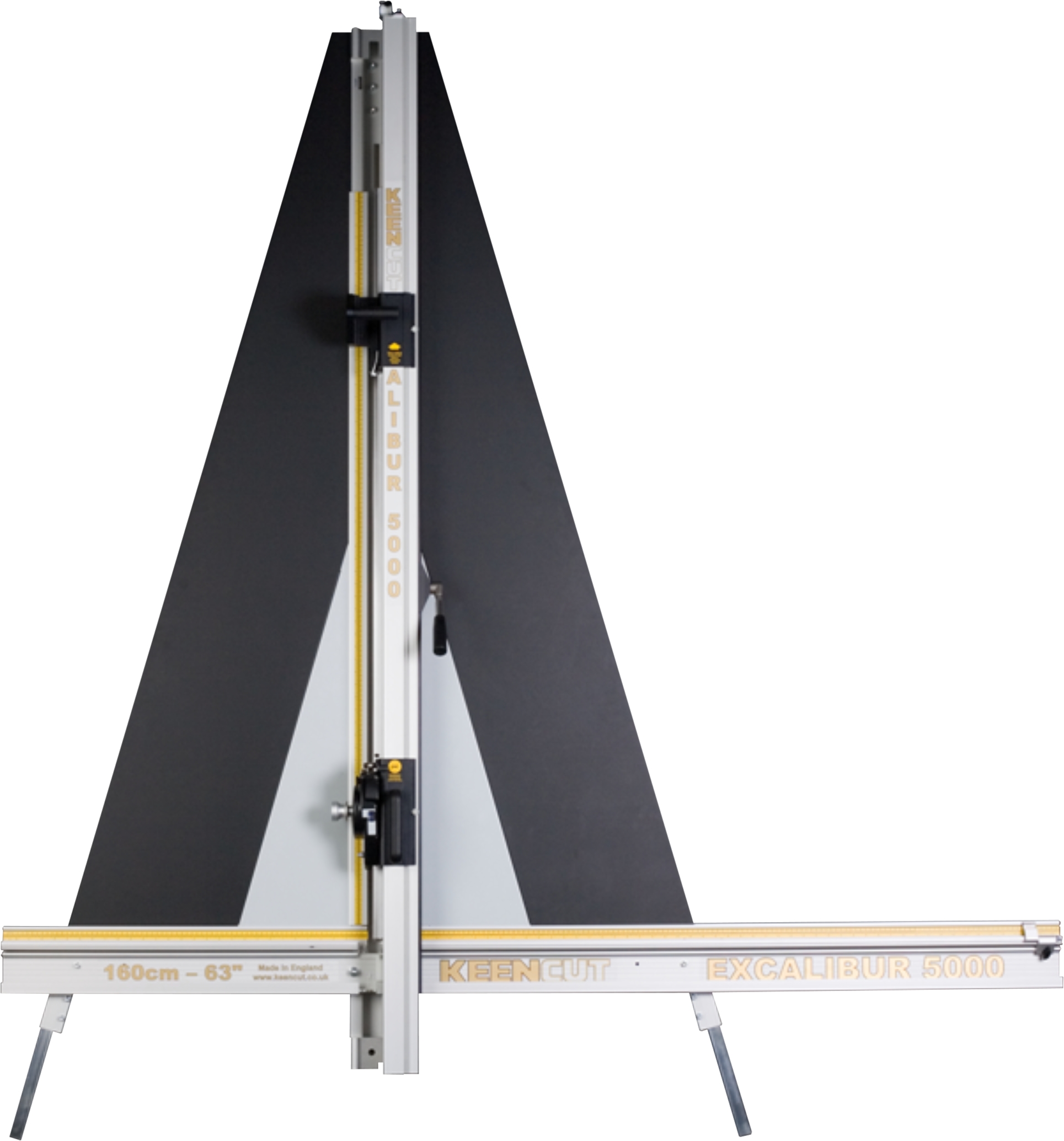

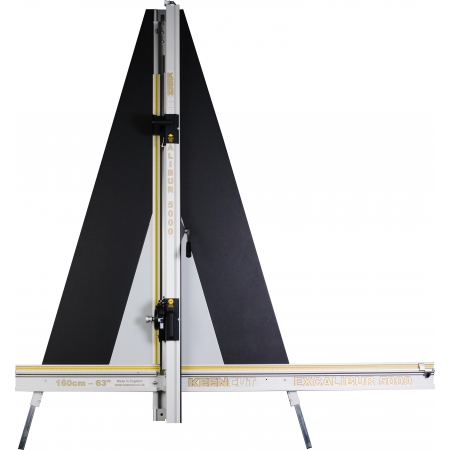

Excalibur 5000

Features

Consistent perfect cuts every time

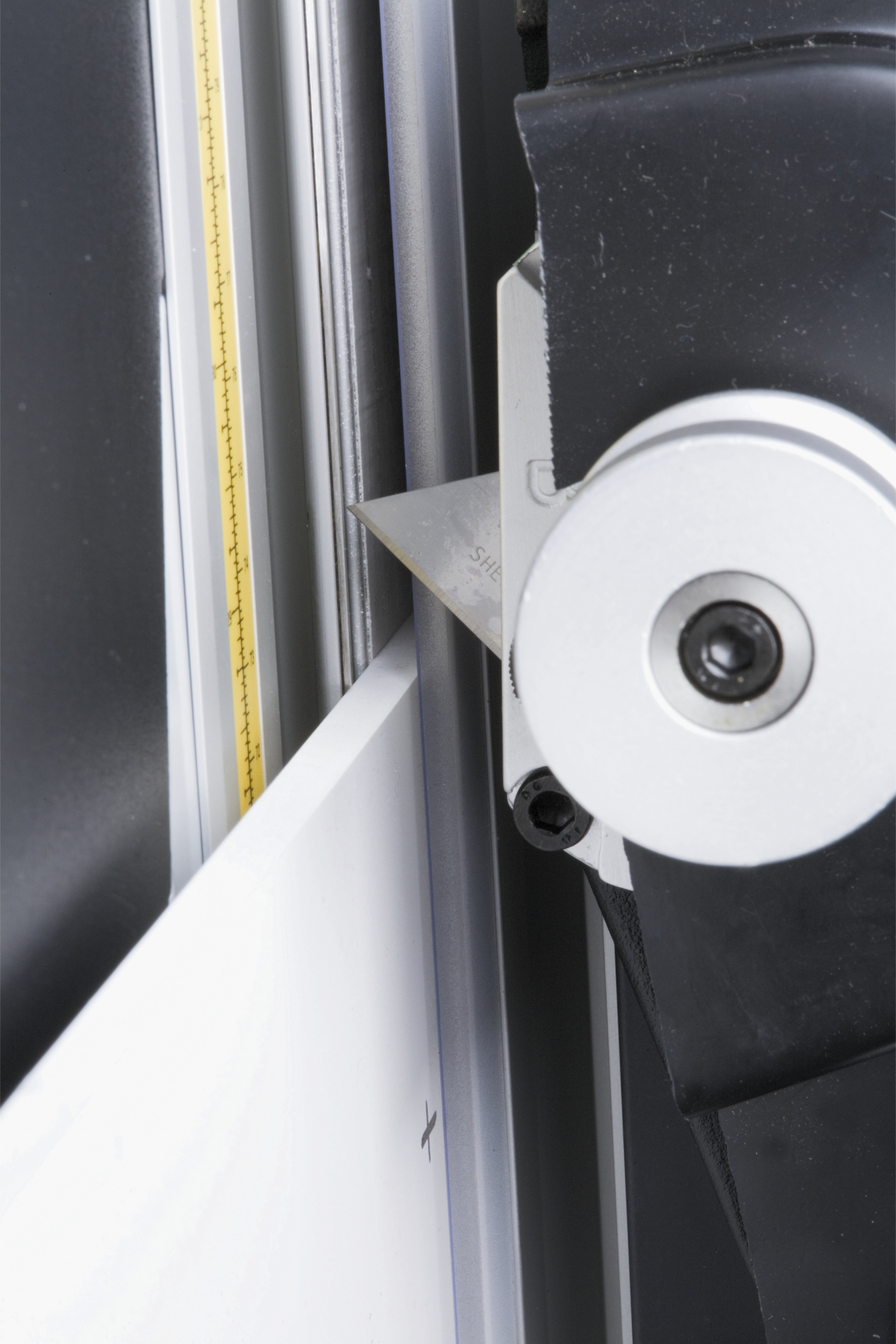

The Excalibur 5000 cuts all materials down the same line, so there is no need to alter production stops for different materials. After a simple initial set-up, the cutter maintains permanent 90-degree accuracy. A one-piece, horizontal squaring arm ensures positioning and rigidity either side of the cut line and accuracy is assured with a clear sightline strip acting as your guide to precise alignment. Materials are then held firmly by a unique pressure-sensitive clamp, which is designed to protect delicate surfaces from damage.

Saves time and money

By reducing set-up and cutting time the Excalibur 5000 increases your productivity. All tools are permanently mounted for instant selection, allowing you to switch between cutting mount board, hardboard, glass and acrylic in seconds. All four blades cut along the same line, so you only prepare one stop setting and one measurement. Everything has been designed to save you time, reduce costly mistakes and reduce waste.

Multiple tools

The two heads house four cutting tools. The lower multi-tool head has a unique ratchet system that provides incremental cutting of thicker materials. The upper twin wheel cutter cuts 3mm (1/8″) MDF in a single pass producing a clean edge. A balance weight parks the twin wheel head at the top when not in use and cutting is achieved without noise, dust or debris.

Reduces fatigue

The counterbalance weight, upright profile and the low friction bearing system combine to produce an easy, smooth cut and reduce user fatigue. The integral counterbalance can be attached to either the multi-tool or twin wheel tool allowing the head to be left in place when loading and unloading materials. Telescopic legs can be adjusted to ensure the most comfortable working height for the user.

Safety by design

To ensure your safety, glass can be scored and broken on the machine. A slightly recessed left-backing panel is designed to break out glass with minimal effort and no need for additional tools. All blades are automatically disengaged when not in use and are securely mounted within the cutter head.

Space saving

To minimise the required floor space, the Excalibur 5000 comes complete with wall mounting brackets. For those with limited wall space or requiring more flexibility a free-standing kit is also available.

Five year guarantee

By manufacturing in-house, with only the highest quality materials, Keencut can guarantee that the Excalibur 5000 will provide reliable long-lasting and accurate service. All Keencut products are offered with a comprehensive five year guarantee. Register your product to activate your guarantee >

In the box

100 medium duty utility blades

Two glass cutting wheels (1 is mounted)

Twin wheel cutter (mounted)

Wall mounting bracket

Materials cut

Mountboard

Conservation board

MDF ≤ 3mm (3/32″)

Cast acrylic / Plexiglas ≤ 3mm (3/32″)

Glass ≤ 6mm (1/4″)

Foam centred board ≤ 13mm (1/2″)

Cardboard ≤ 13mm (1/2″)

PVC Foamboard (Forex)

Corrugated plastic

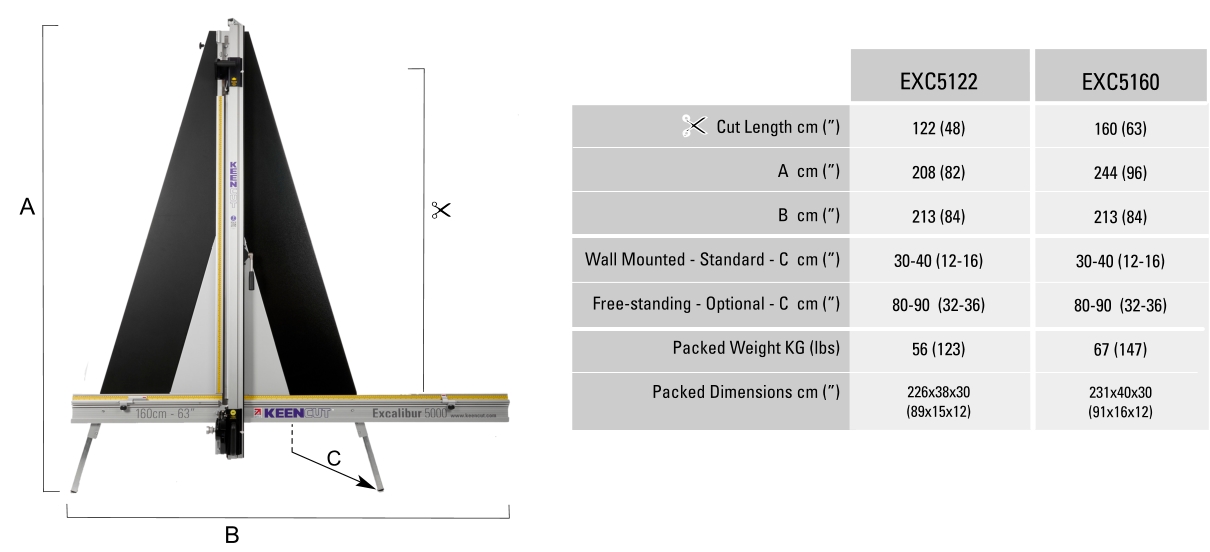

Dimensions

Reviews

"We chose this product because of the affordable prices and small size, easy to store"

“We purchased this item in 2013. This is our first Keencut product and we are very satisfied with it. We use it for Foam Core. Core-Plast, Centra, Corrugated Paper and things of that nature. We chose this product because of the affordable prices and small size, easy to store. Over all we love the product and sometimes wish it was a little taller for bigger jobs”

Juan Millan of Chimes Printing (USA) – https://www.chimesprinting.com/contactus.html

Accessories

Free standing kit

Enables the Excalibur 5000 to be installed without fixing to a wall

Product information >

Medium duty utility blades

A double ground edged, reversible blade suitable for cutting all types of materials

Product information >