SteelTrak slideway straightness test

Before you start

Before starting any work, check the machine is firmly fixed to the wall or freestanding leg and that you have the following equipment:

- A length as long as the cutter of PVC foamboard, MDF or similar at least a 30cm (12″) wide

- Self-adhesive packing tape

- Measurement table

- Pencil or pen to note measurements

1. Prepare board and place board in cutter

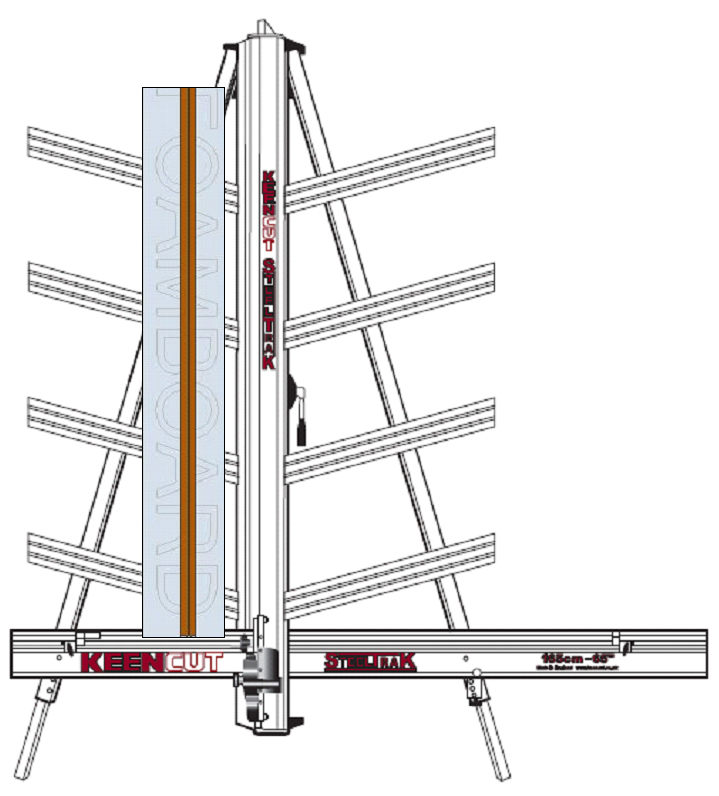

A length of PVC foamboard, MDF or similar, will be required to carry out this test. It should be 30cm (12”) wide and ideally the maximum length that will fit in the cutter. Stick a strip of self adhesive packing tape along the centre of the board, as shown below. Place the board in the cutter, so the tape is approximately central, select the cutting blade but disengage the ratchet (see page 6.4, item 1 in the manual). Using finger pressure, apply very light pressure to the blade holder and cut down the length of the tape, so only the tape itself is cut. Do not cut through the PVC foamboard as well.

2. Turn board and repeat

Spin the PVC foamboard through 180° keeping the tape visible and place it back in the cutter. Position the board so that the blade will cut about 1mm (1/16”) away from the previous cut at both the top and the bottom of the cut. As before, apply light pressure to the blade holder and cut down the length of the tape only.

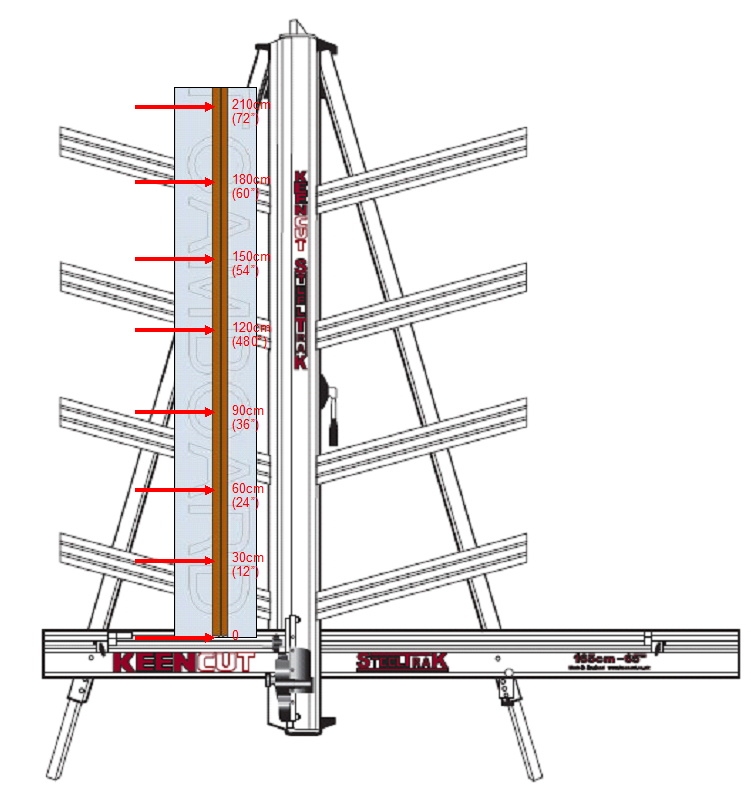

3. Take measurements and record results

Starting at one end, measure the gap between the lines every 30cm (12”) along the length of the tape. It is important that the measurements are taken as accurately as possible. List the measurements on the table as shown below. Don’t forget to state whether your measurements are in millimetres or inches.

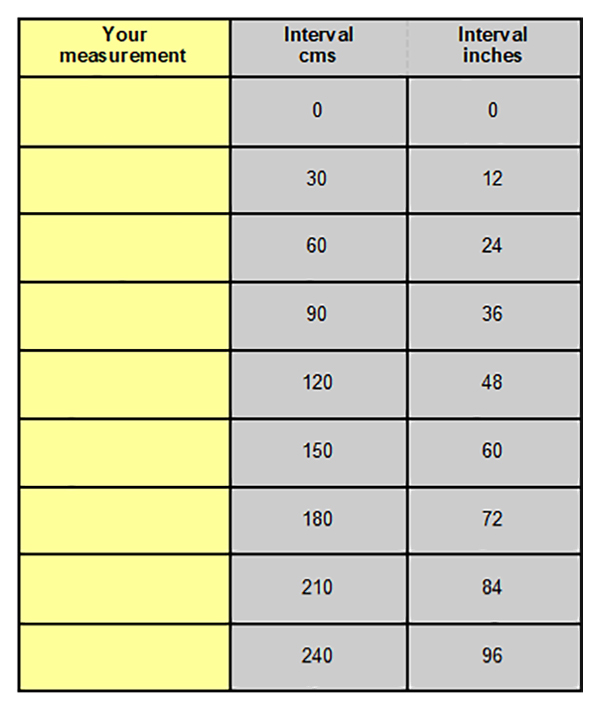

4. Recording table

As long as the two cut lines do not cross, it will be easier to measure the gap if you remove the strip of tape between the two cut lines. Once the measurements are recorded on the table, please email it to [email protected], Keencut will analyse the measurements to assess the straightness. Please state whether your measurements are in millimetres or inches.