How to replace the push rod assembly on the SteelTrak and Excalibur

Depending on the machine you have to do this you will need one of the following assemblies:

The SteelTrak & Excalibur push rod assembly >

The SteelTrak 250cm push rod assembly >

Tools required

- Allen (hex) key 4mm

- Allen (hex) key 5mm

- Small screwdrive or steel ruler

- Pen and paper

- 2 x 100mm open ended spanner/wrench

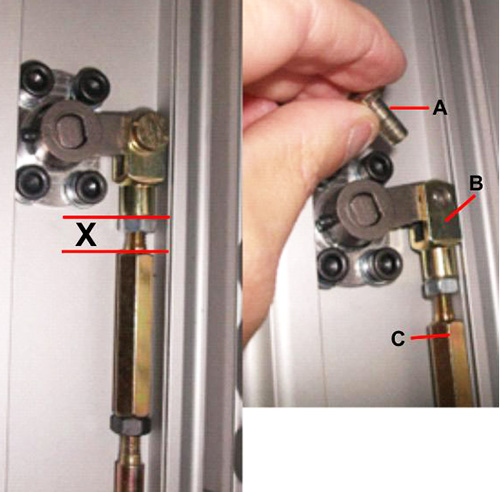

- Loosen the two locking nuts (the black one has a left hand thread) using a 100mm open ended spanner/wrench.

- Rotate the adjuster (C) to close the gap between itself and the clevis (B) as much as possible, sometimes this can be done using your fingers rather than the spanner/ wrench.

- Remove the pin (A) from the lower clevis (B).

- Reassembly is the reverse procedure to removal, set the clamp adjuster (C) near to the dimension ‘X’ measured orignally.

- To adjust the clamp a simple test can be done with a sheet of paper, the clamp adjuster (C) is set correctly if the clamp grips the paper at the top and the bottom of the machine. (NOTE ‐ it may not grip the paper in the middle of the clamp bar but this is normal).

- Once you are satisfied tighten the locking nuts. Tighten the silver locking nut first (clockwise) whilst holding the adjuster in position with a second spanner/wrench.

- Now tighten the black locking nut (counter clockwise) again make sure the adjuster does not move.

- Operate the clamp a few times and check again, adjust further if necessary.

- Once satsified replace the black cover strips.