Evolution3 FreeHand User Guide – Double Graphik tool head

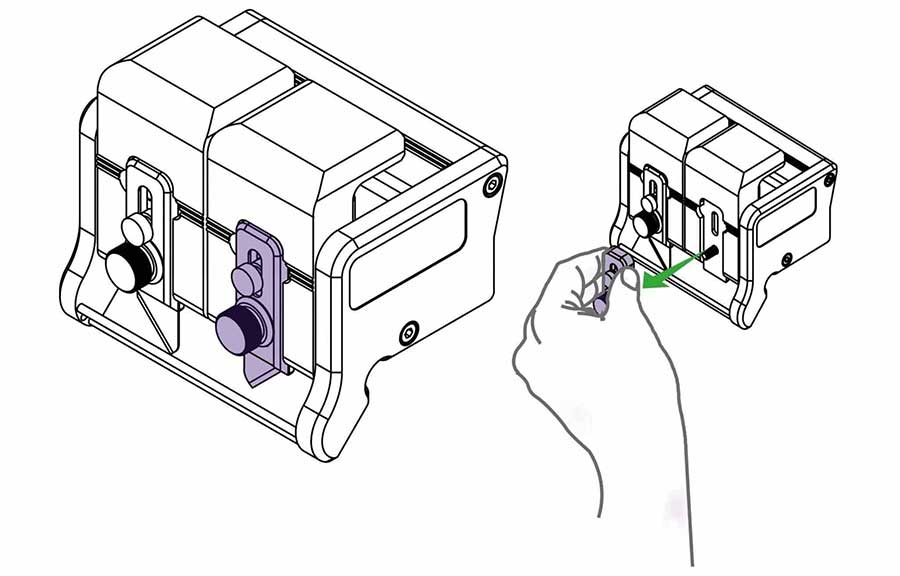

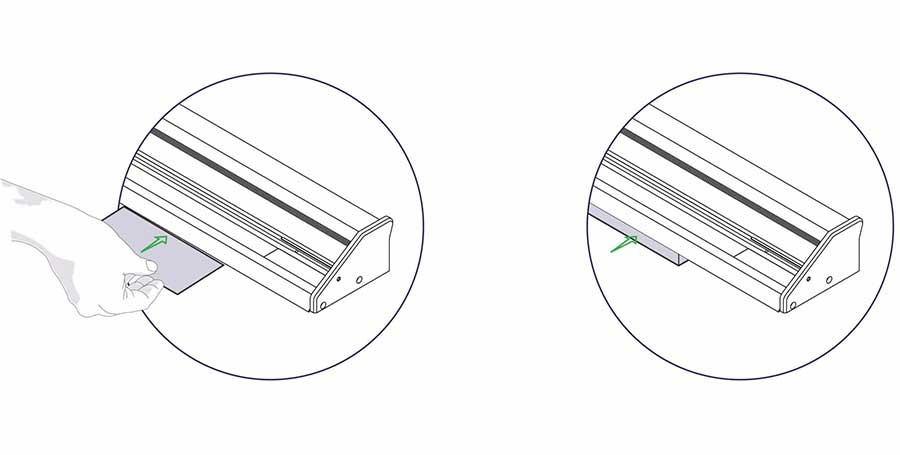

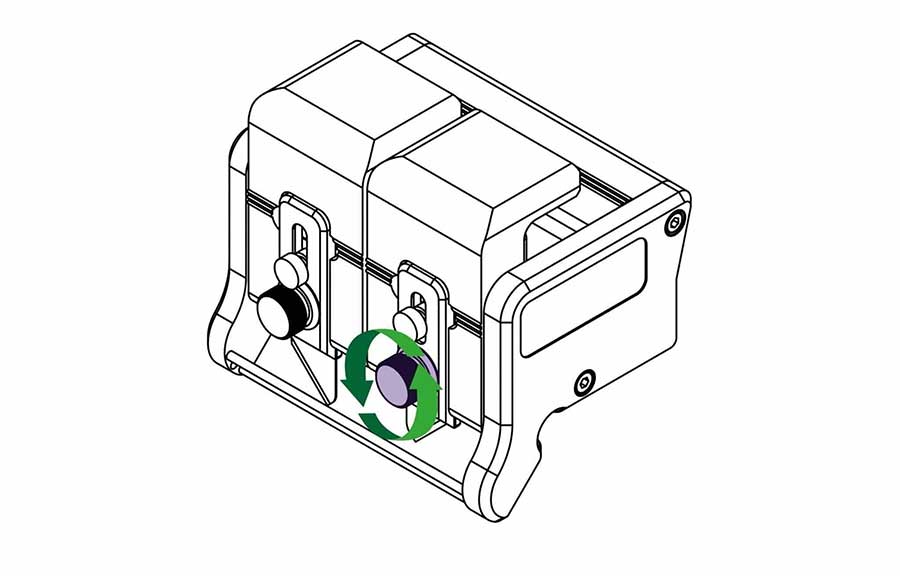

Undo the highlighted knob to remove the magnetic blade clamping plate.

Pull the magnetic blade clamping plate away from the cutting head.

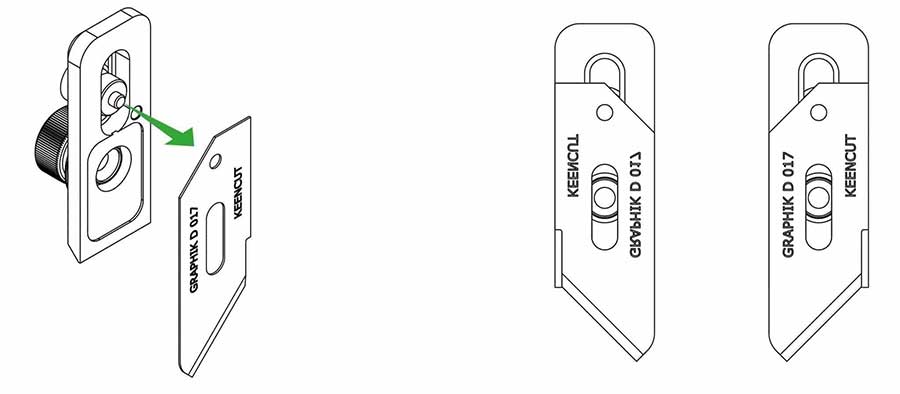

Lift off the blunt blade (if there is one) and replace with a new Graphik blade, check it is facing the correct way for your desired direction of cutting. Place the small pin in the hole at the top of the blade and align with the edge of the clamping plate.

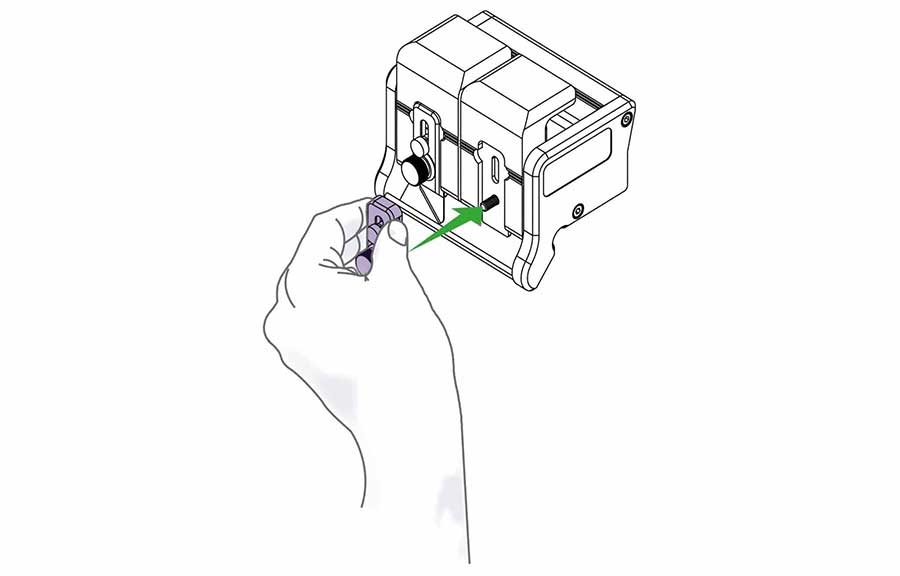

Replace the blade clamping plate onto the blade holder but do not tighten fully until the blade depth has been set. Repeat on the other blade holder if required.

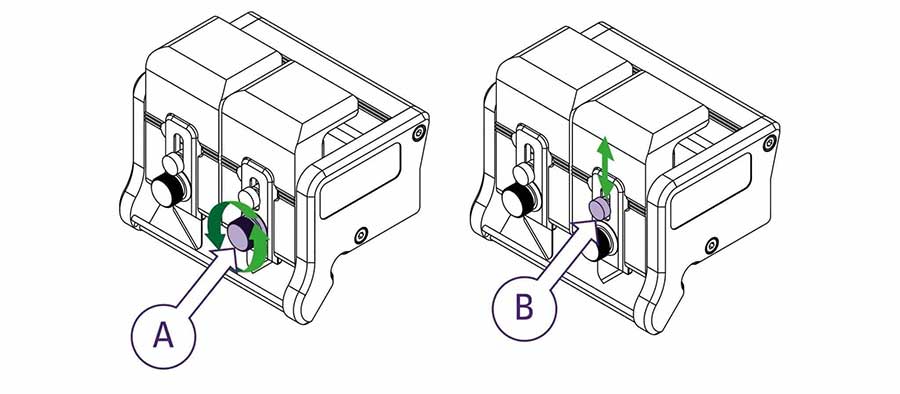

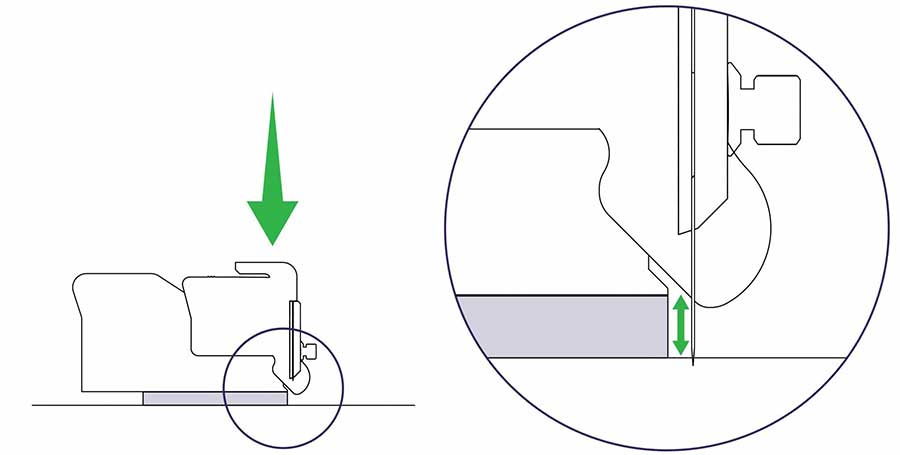

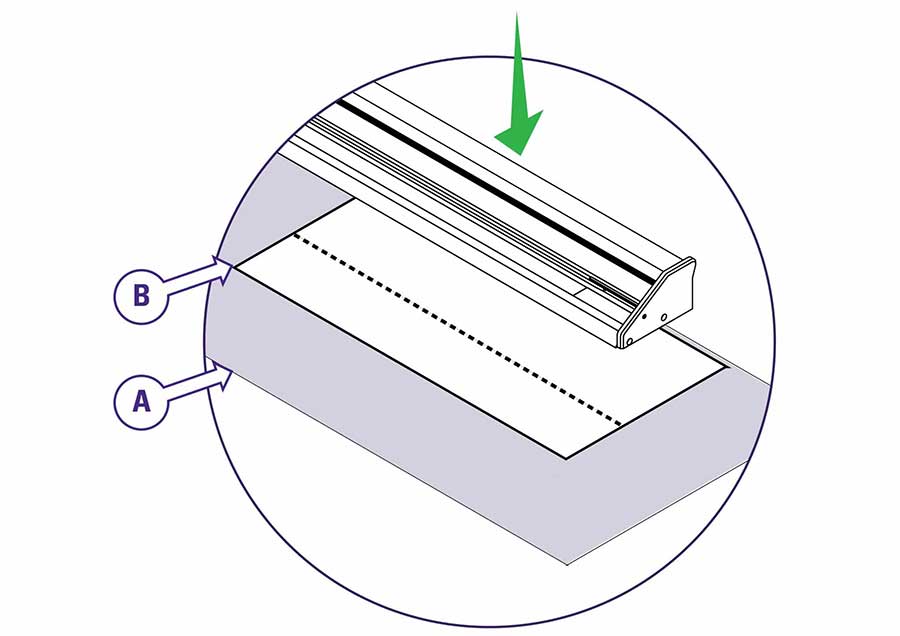

To adjust the height of the blade, loosen knob ‘A’ by a half to one full turn. Move knob ‘B’ up or down until the blade is long enough to just cut through the material.

Place a piece of the material under the cutter bar so it does not protrude past the edge of the cutter bar and the blade can be seen against the edge of the material.

Tighten ‘A’ to lock the blade in chosen position.

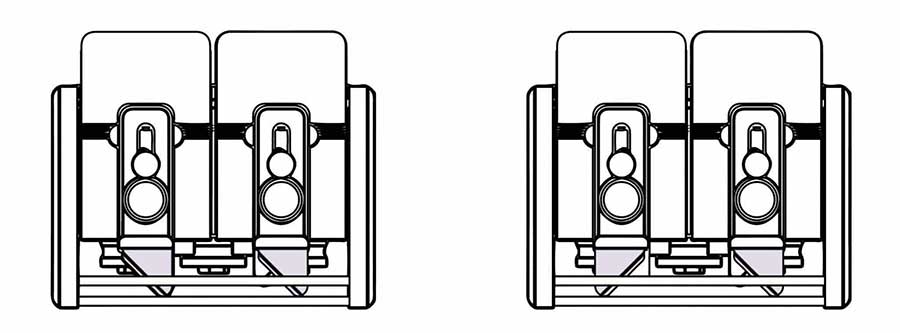

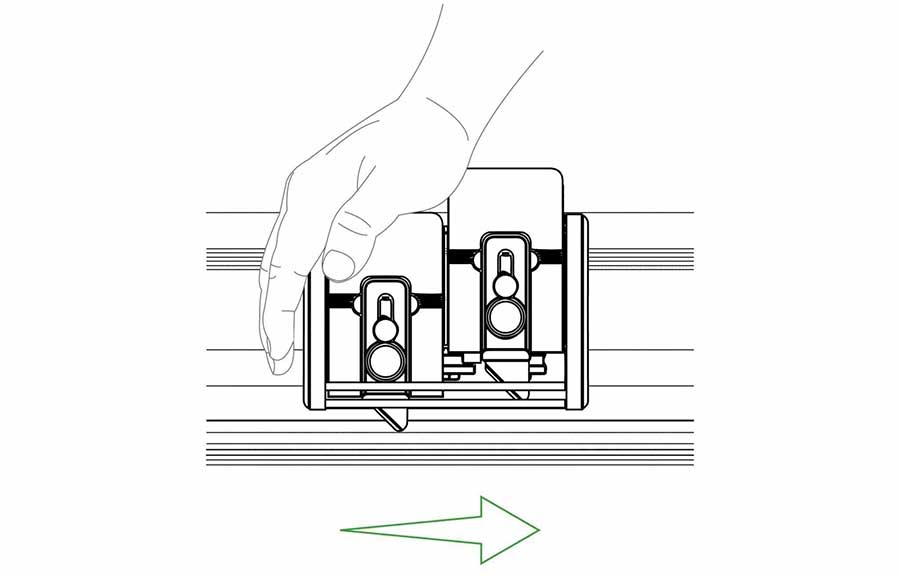

The design of the Graphik blade allows it to be set in the blade holder to cut in either direction. The cutting head can be used with both blades cutting in the same direction or in opposing direction.

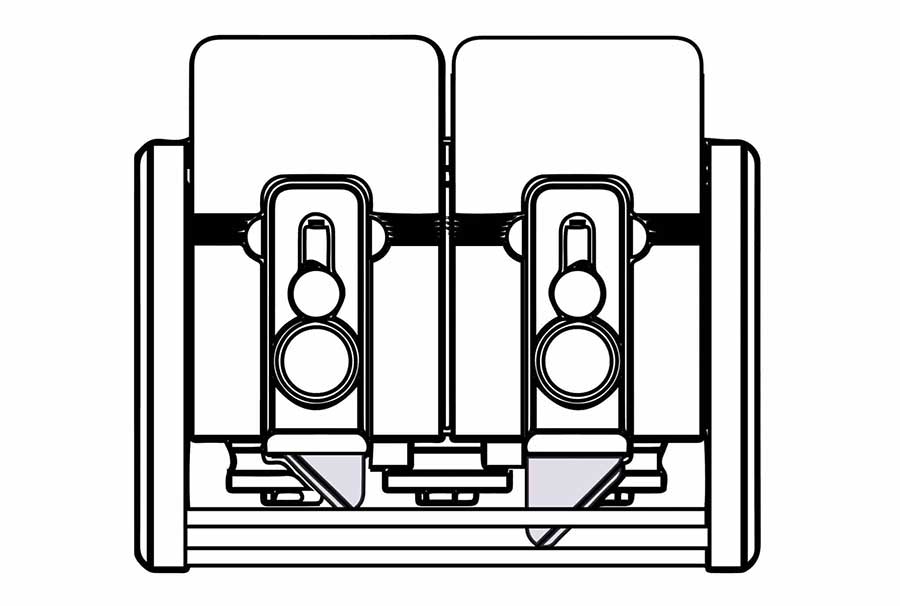

The blades also have adjustable cutting depth, so if a thick material is being cut on a long machine such that it is beneficial to make two cuts, one blade can be set to cut half the thickness in one direction and the other to cut full depth on the return journey.

Place the cutting mat (A) on the work surface then the material to be cut (B) making sure the whole length of the cut line is over the cutting mat. Place the FreeHand on the material near to the cutline.

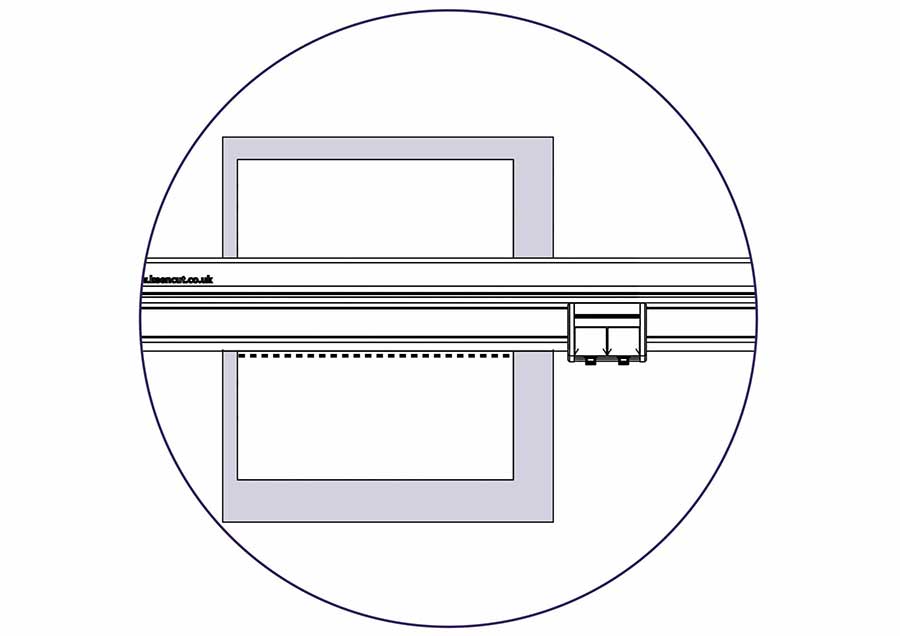

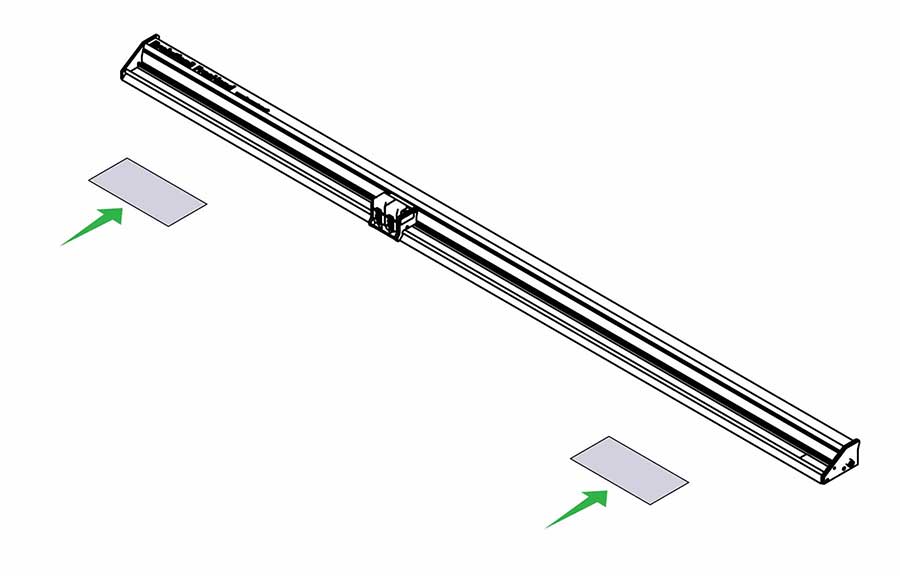

Lift and move one end of the cutter so the sightline strip (clear plastic strip running along cutting edge of the FreeHand) aligns with the cut line, then repeat at the other end. Look down vertically and check the sightline strip aligns with the cut line before making the cut.

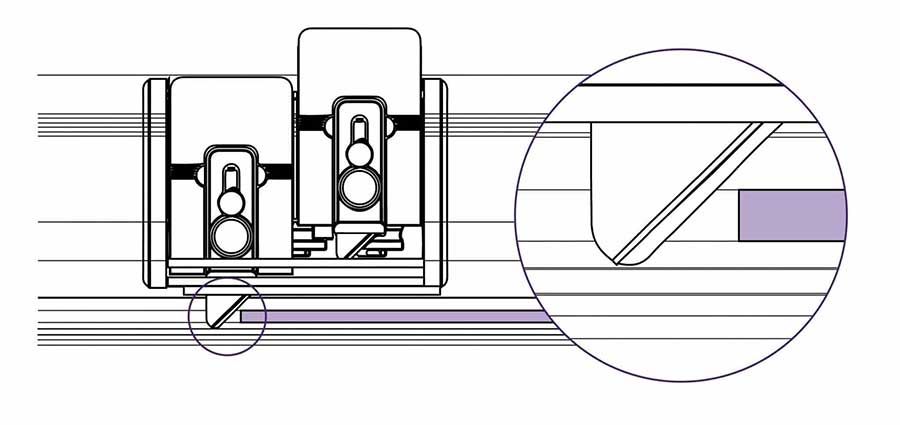

When cutting thick, tough materials such as PVC foam board and fluted plastics such as Correx or Coroplast, set the blade depth so the blade tip protrudes only 1-2mm (1⁄16”) through the thickness of the board and cuts from left to right.

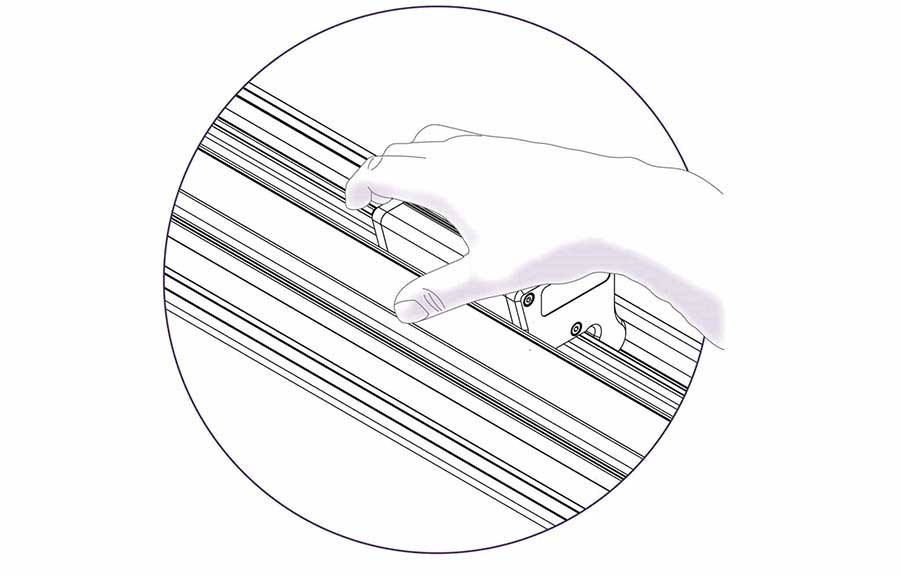

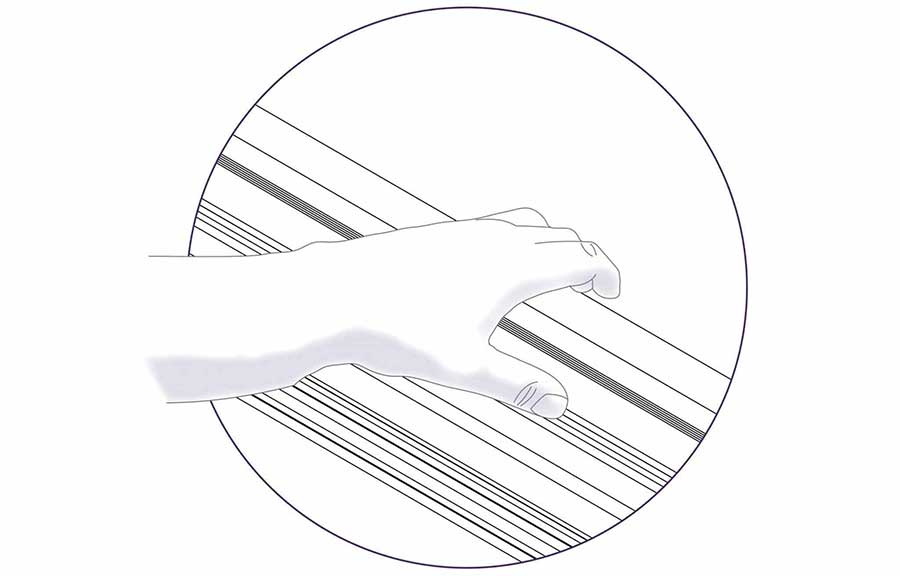

Position the cutting head to start the cut, turn your body to face to the right and place the palm of your right hand on the cutting head.

Take a firm grip on the cutter bar with your left hand.

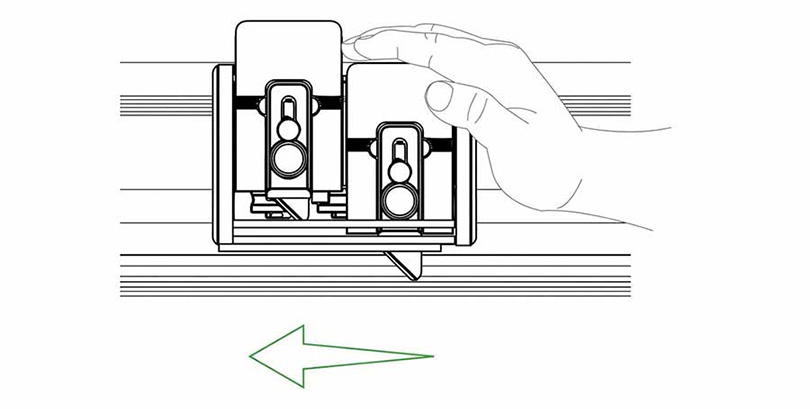

Depress the blade holder and push the cutting head using the strength across your shoulders.

Tip: If the material is too thick to reasonably cut in one stroke the blade can be lowered partially and the board cut in a number of strokes.

Cutting Aluminium Composite Panels is not recommended using the Graphik tool head.

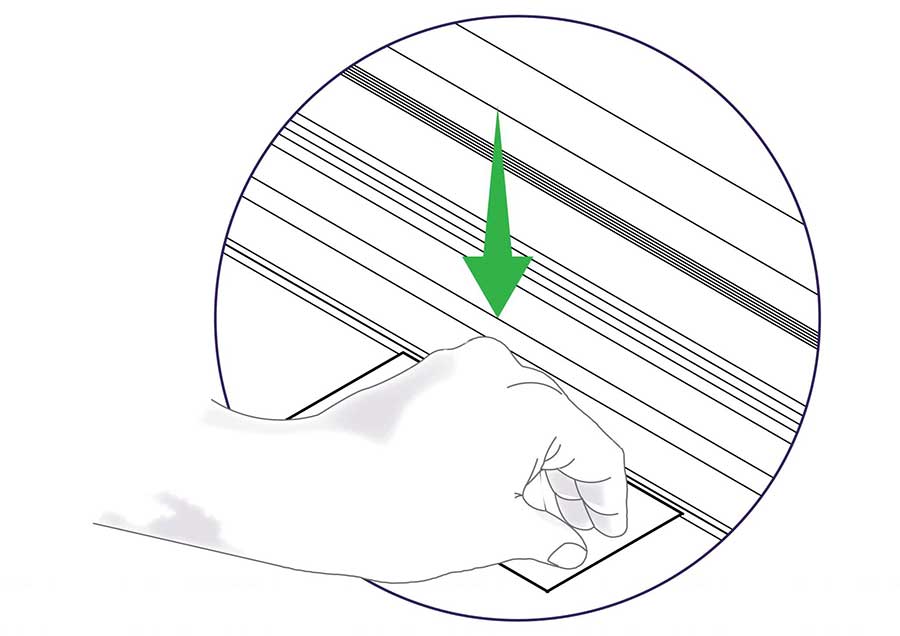

Thin materials such as paper and plastic films are easily cut but attention should be given to supporting the material at the beginning of the cut. Pressing down lightly on the edge of the material with your index finger or thumb will prevent the material creasing when the blade starts cutting.

Scoring Acrylic and other plastics can be achieved by setting the blade at minimum depth and running the blade backwards across the surface whilst applying firm downward pressure on the blade holder.

Remove the material from the cutter for snapping by hand, some plastics may benefit from being scored multiple times.

When cutting a small piece of board place it at one end of the cutter and place a scrap piece at the other end to keep the cutter bar parallel to the base.

Lift off the blunt blade (if there is one) and replace with a new Graphik blade, check it is facing the correct way for your desired direction of cutting. Place the small pin in the hole at the top of the blade and align with the edge of the clamping plate.

To adjust the height of the blade, loosen knob ‘A’ by a half to one full turn. Move knob ‘B’ up or down until the blade is long enough to just cut through the material.

Place a piece of the material under the cutter bar so it does not protrude past the edge of the cutter bar and the blade can be seen against the edge of the material.

The design of the Graphik blade allows it to be set in the blade holder to cut in either direction. The cutting head can be used with both blades cutting in the same direction or in opposing direction.