How to finish the corner of aluminium composite board

Before you start –

Before starting any work, check that you have the following equipment:

- A sharp blade or chisel

Please note: These instructions will only be relevant to certain board qualities and specifications

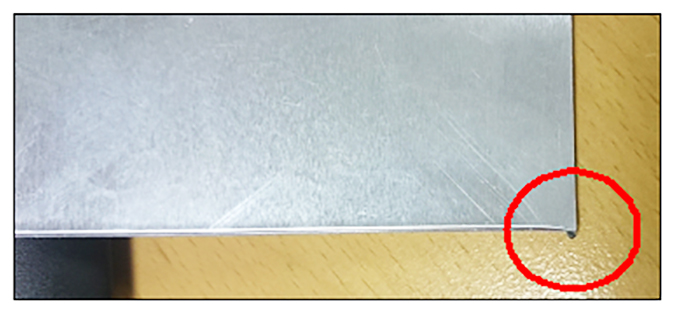

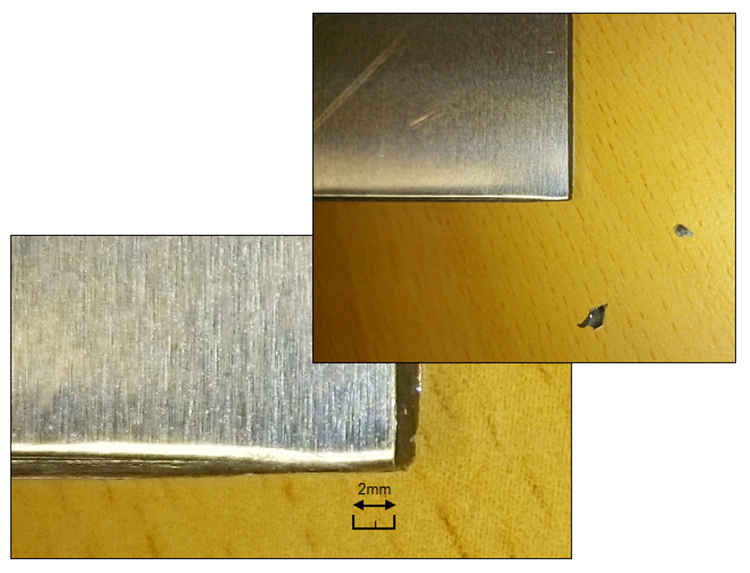

What causes a 'pip' in the corner of ACP board when cut on a SteelTrak

The clever design of the SteelTrak cutting wheels means the edge of a composite board is finished to a smooth edge as the head passes, however some boards leave a very small ‘pip’ in the corner at the end of the cut. This is caused by the board pushing itself apart when the wheels reach the bottom edge. This is a property of the board and is affected by a number of different things, including blade sharpness and board quality/specification. The weaker the core plastic, the more the board will push apart, rather than staying in place for the wheels to cut through it.