Fitting Round Shaped Silicon Cords To Cutter Bar Base (SILYR)

This process for replacing silicon cords can be used on any cutter bar base where they are used.

Before you start

Before starting any work check that you have the following equipment:

- A rounded smooth metal or hard plastic edge

1. Start placing the cord in the groove

It is important that the silicone cords are fitted such that they do not feel bumpy along the length of the groove or are stretched and loose in the groove. The cord should be about 0.5mm (0.02”) proud of the aluminium surface.

Start somewhere about half way down the groove and stretch a small length of the cord and press it down into the groove.

2. Stretch and press the cord in place

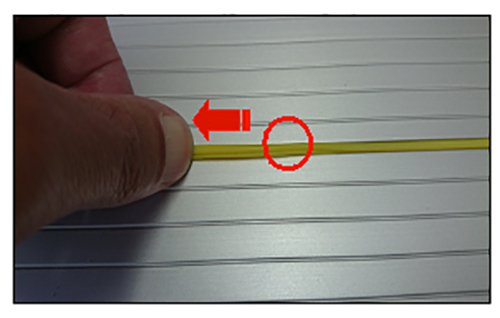

Press down hard on the cord at the point it emerges from the groove (red circle) and with your other hard stretch about 5cm (2”) of the cord and push it into the groove with your thumb. Ensure the cord along this short length is sitting fully in the groove by pressing with your thumb.

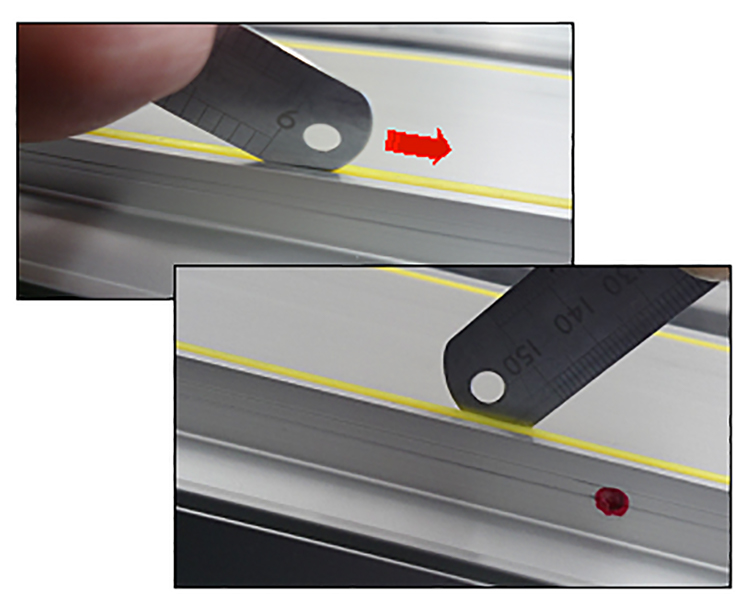

3. Take hard edge and press into groove

When approx. 20cm (8”) of cord has been pressed into the groove take the steel rule (or similar implement, see above) insert it between one edge of the groove and the silicone cord and run it along the cord towards the half way point of the groove (where the cord was first inserted). This performs two jobs, it pushes the edges of the cord firmly into place in the groove and it removes any remaining stretch left in the cord. Repeat along the other side of the groove.

Continue in this fashion working away from the halfway point of the groove with both ends of the cord and then using the rule to push the cord back towards the centre.

When complete check along the length of the cord to ensure it is flat and slightly proud of the aluminium surface. Finally trim the ends of the cord with a sharp knife.