How to replace the PVC panels on the Excalibur 6000

To do this you will need the Excalibur 6000 Replacement PVC panel kit >

Tools required:

- Clean cloth

- White spirit

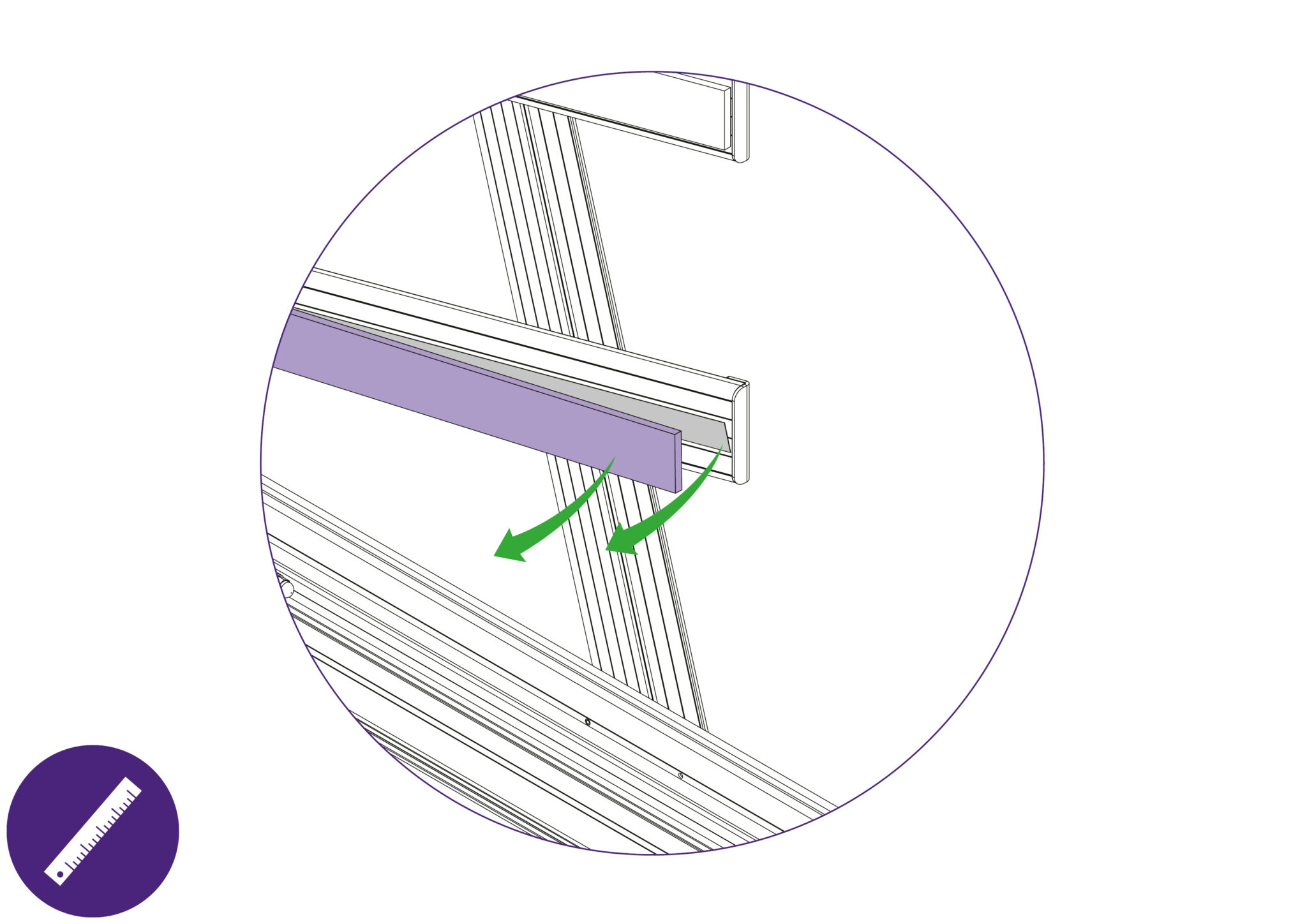

- Rigid item (i.e. Ruler)

NOTE: Do not bend the panels when fitting

Removing from the support arm:

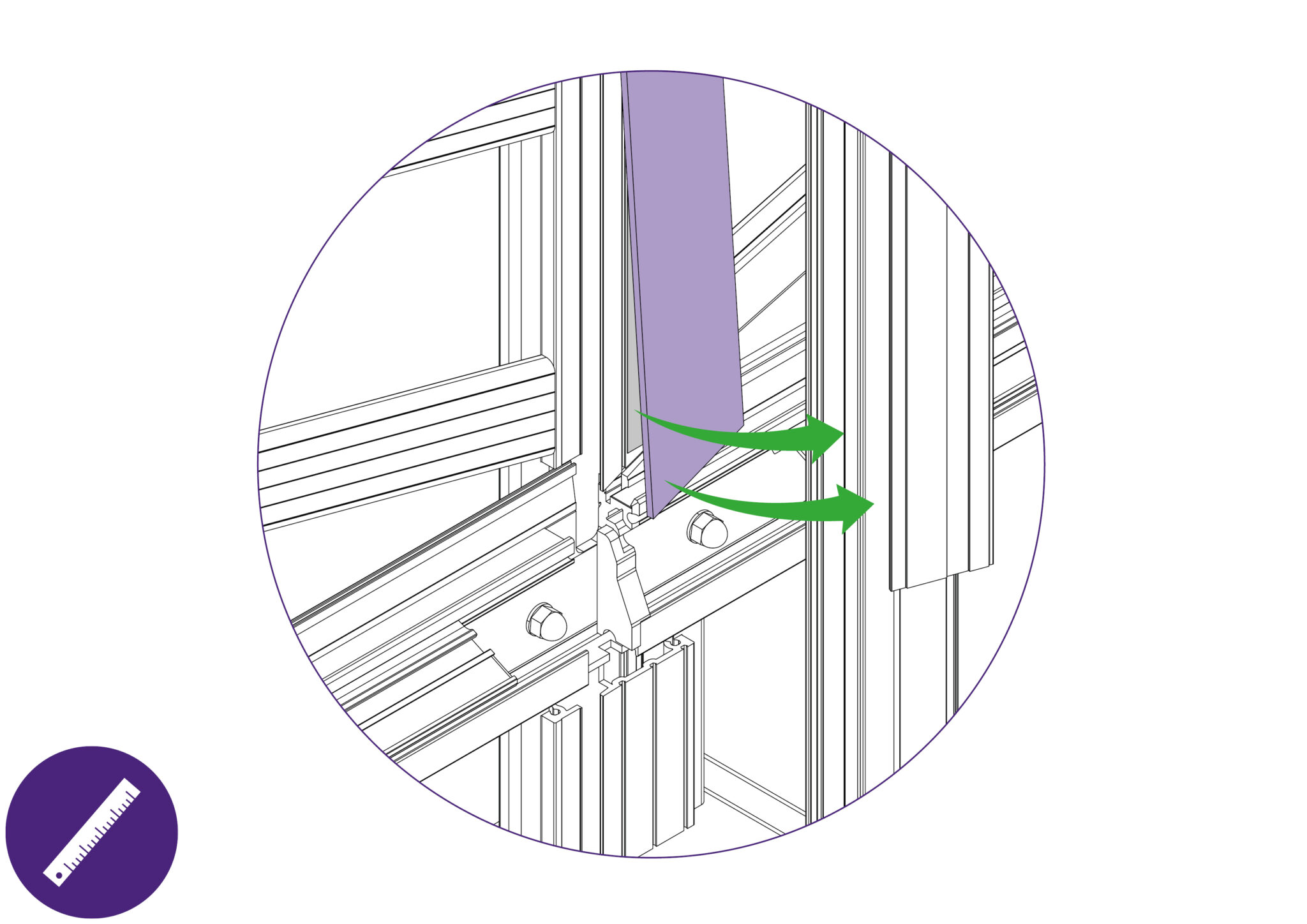

- Slightly remove the edge of the blue support board using a thin and rigid item such as a ruler.

- Peel the layers of double sided tape from the support arm if any tape remains on the surfaces.

- Clean the surface of the support arm with white spirit to clear any remnants of adhesive.

- Ensure the surface is clean and dry before fitting the new blue support oards onto the support arms.

Placing onto the support arms:

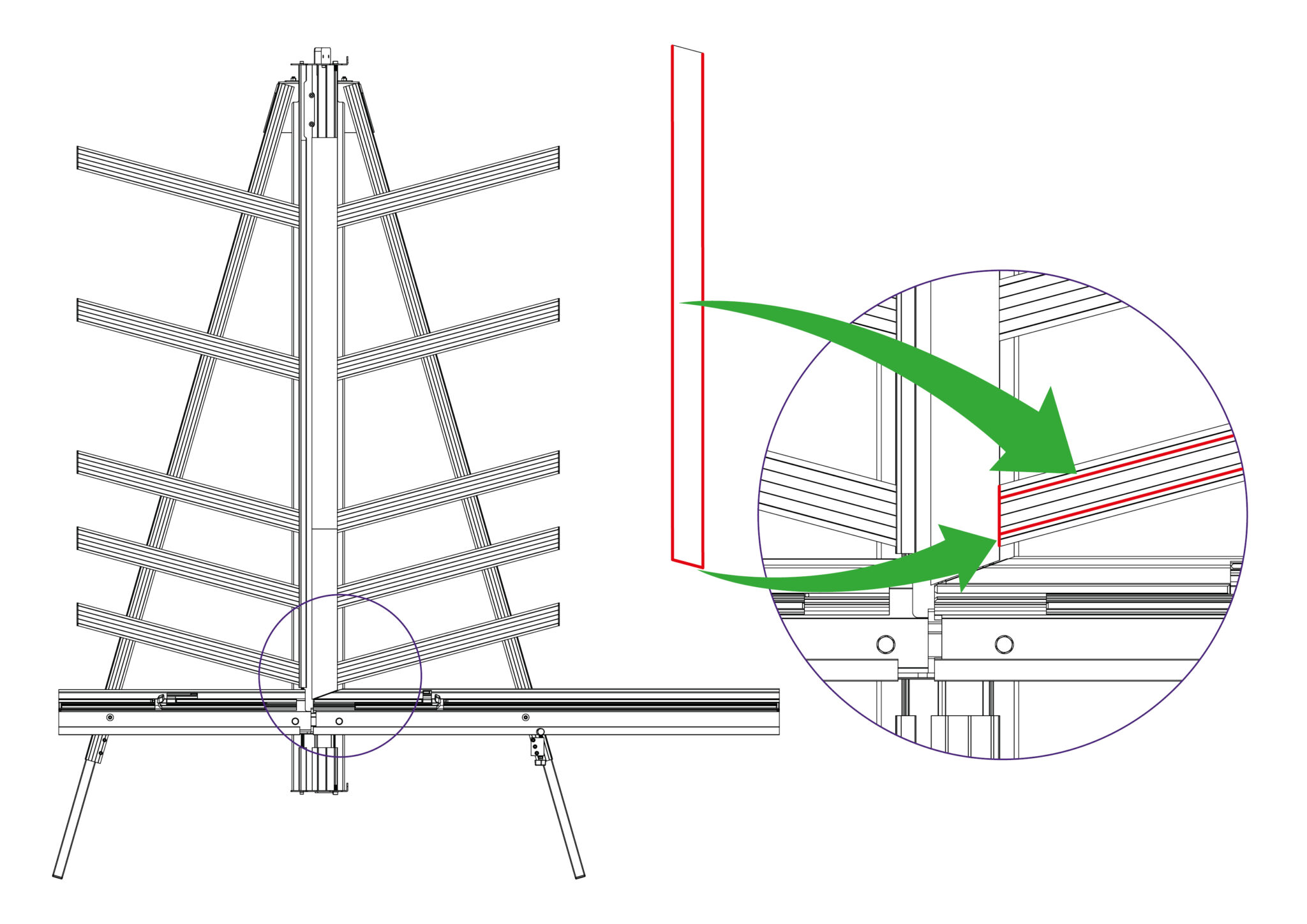

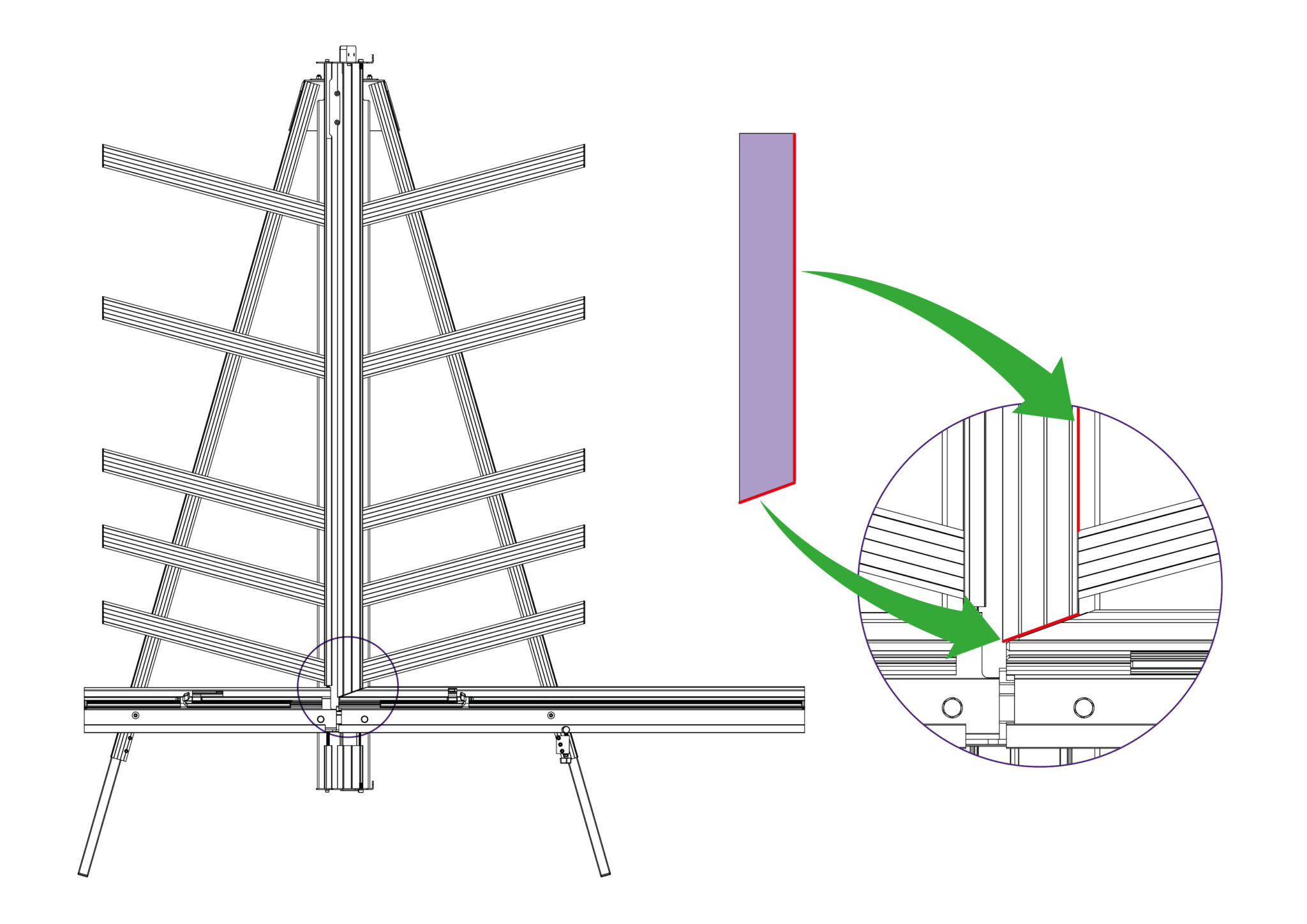

- Peel the release paper from the adhesive face and align the angled face of the board with the angled face of the aupport arm that does not have the end cap attached.

- Ensure that the board in central to the support arm and that it does not overlap on to the main body face.

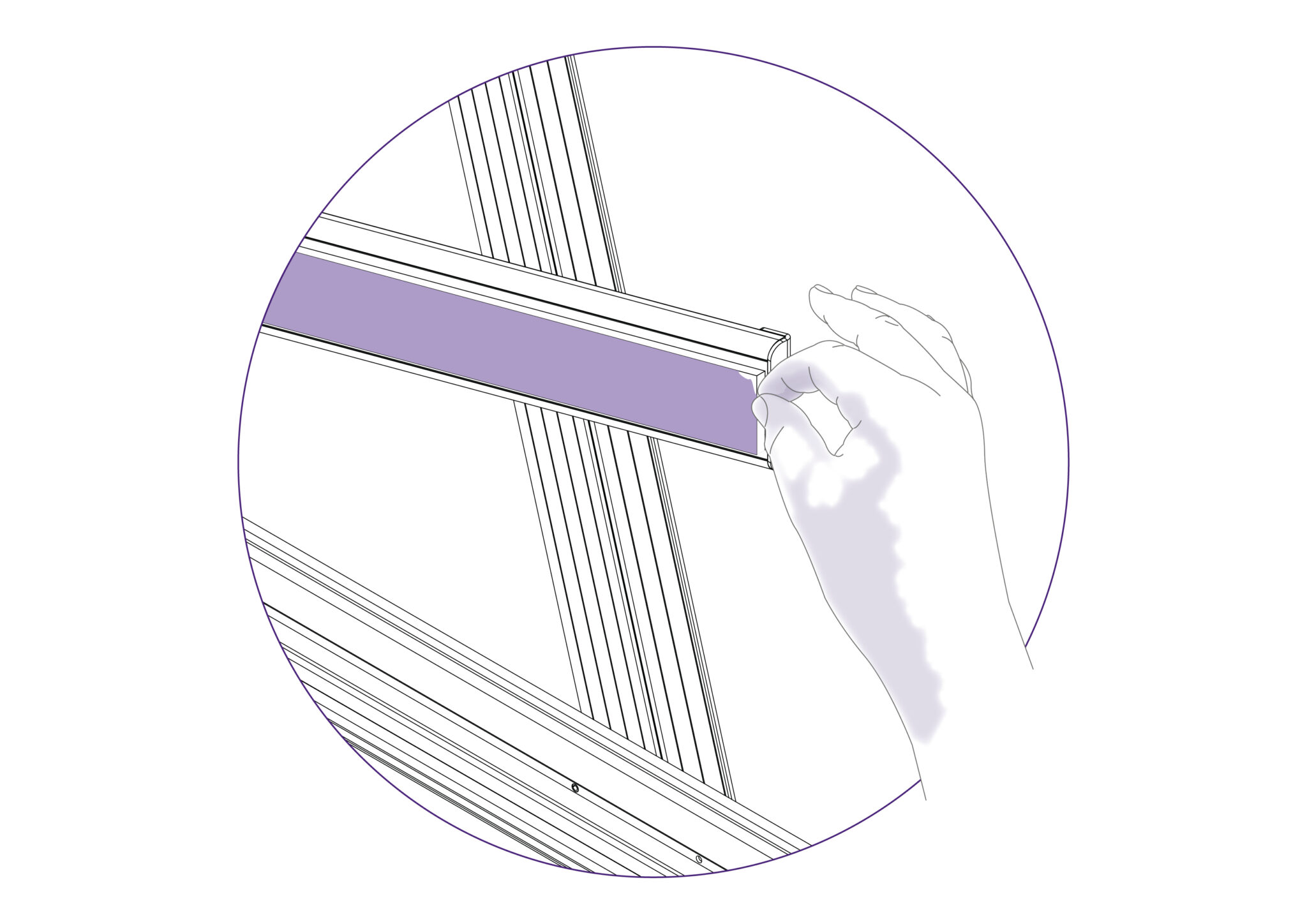

- Proceed to lower the blue support board onto the support arm surface, starting from the aligned edge.

Removing from the main body:

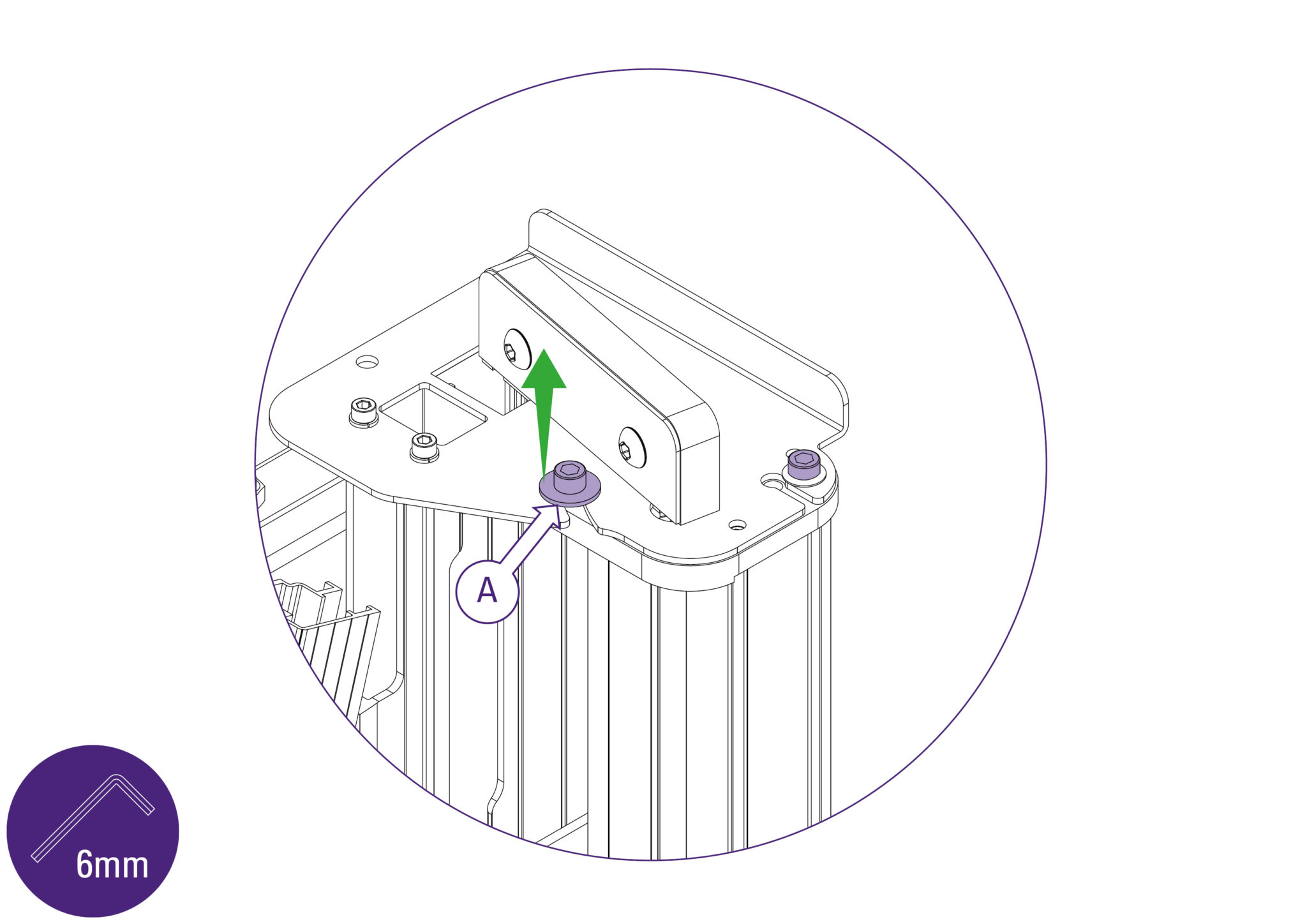

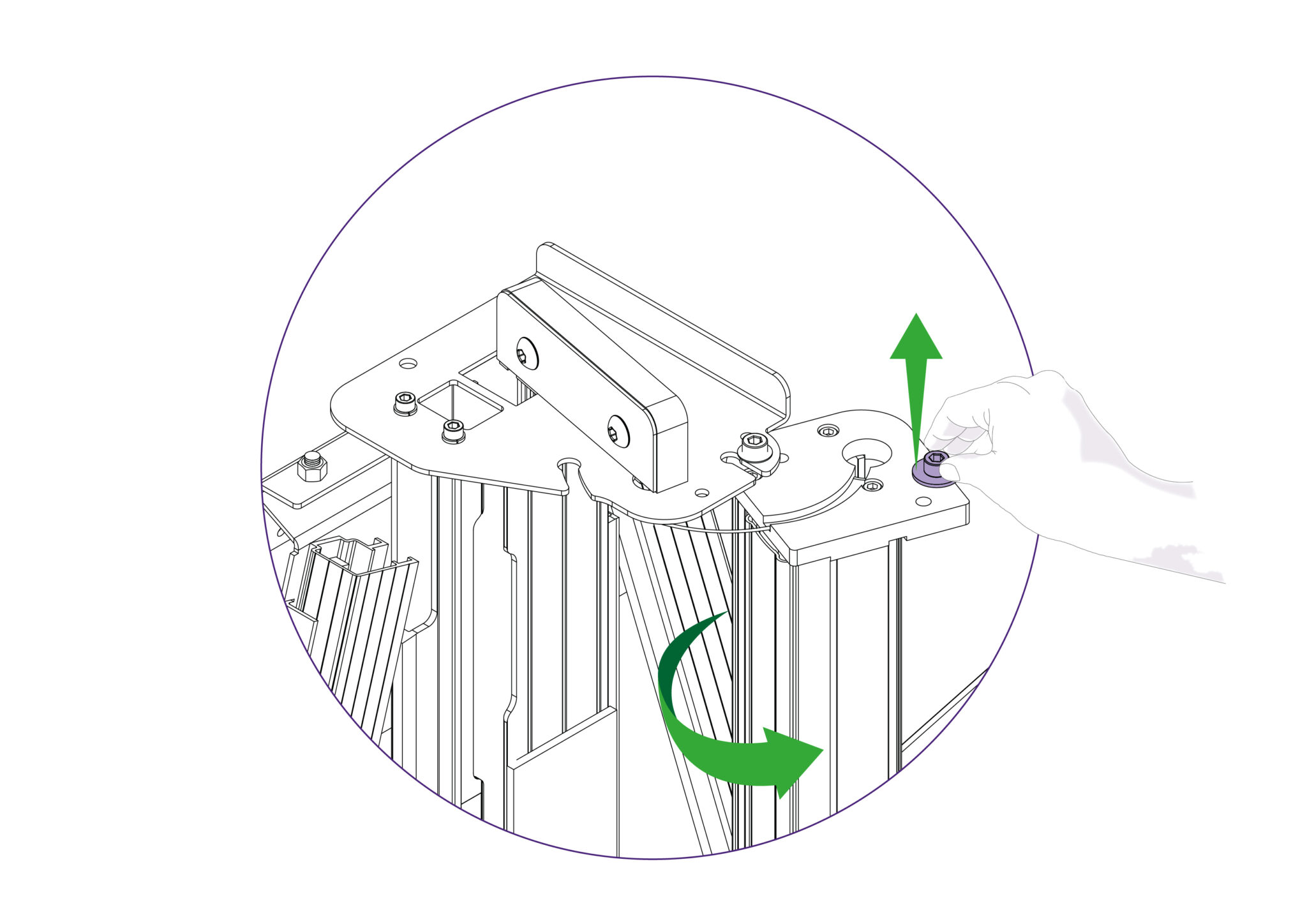

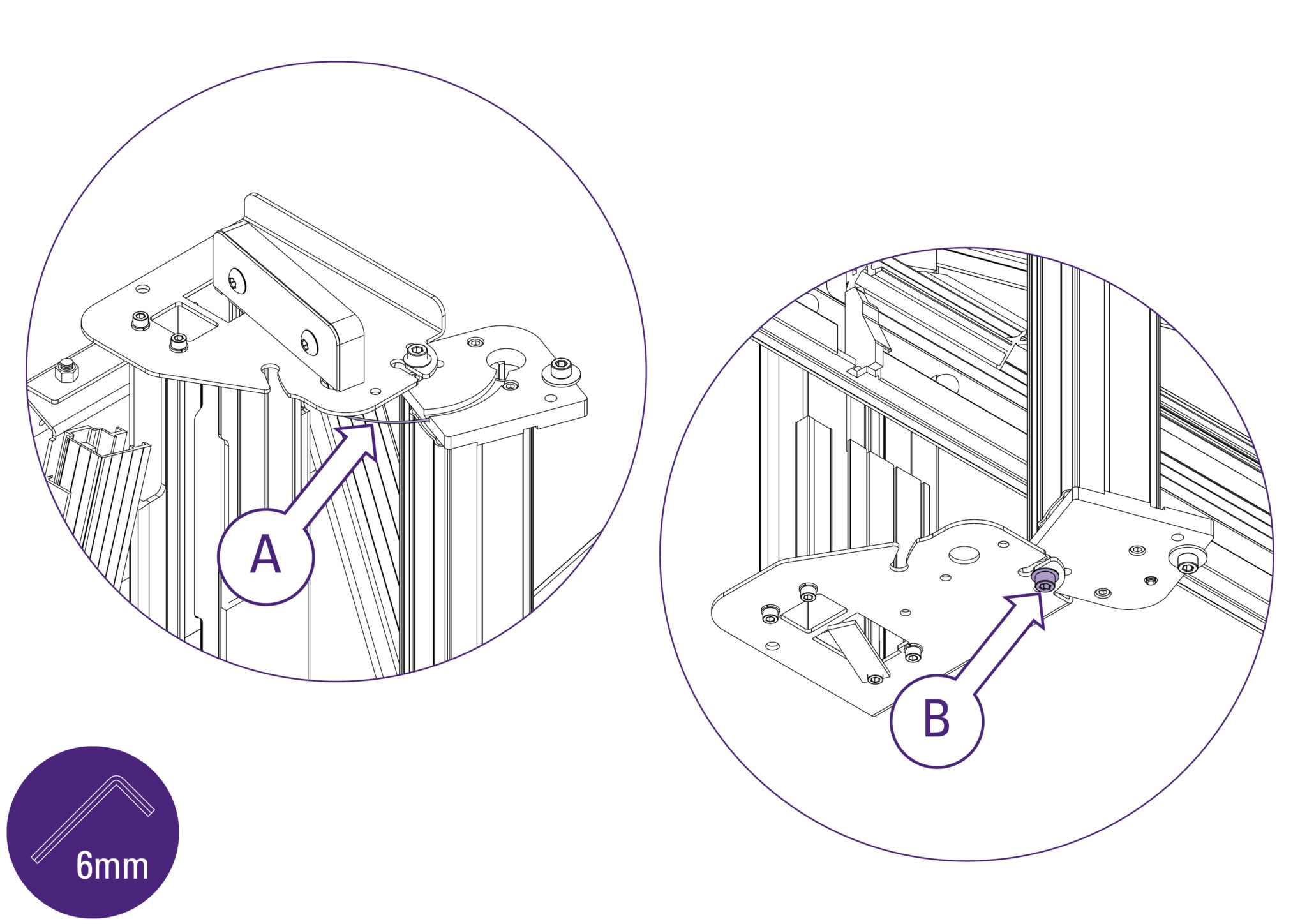

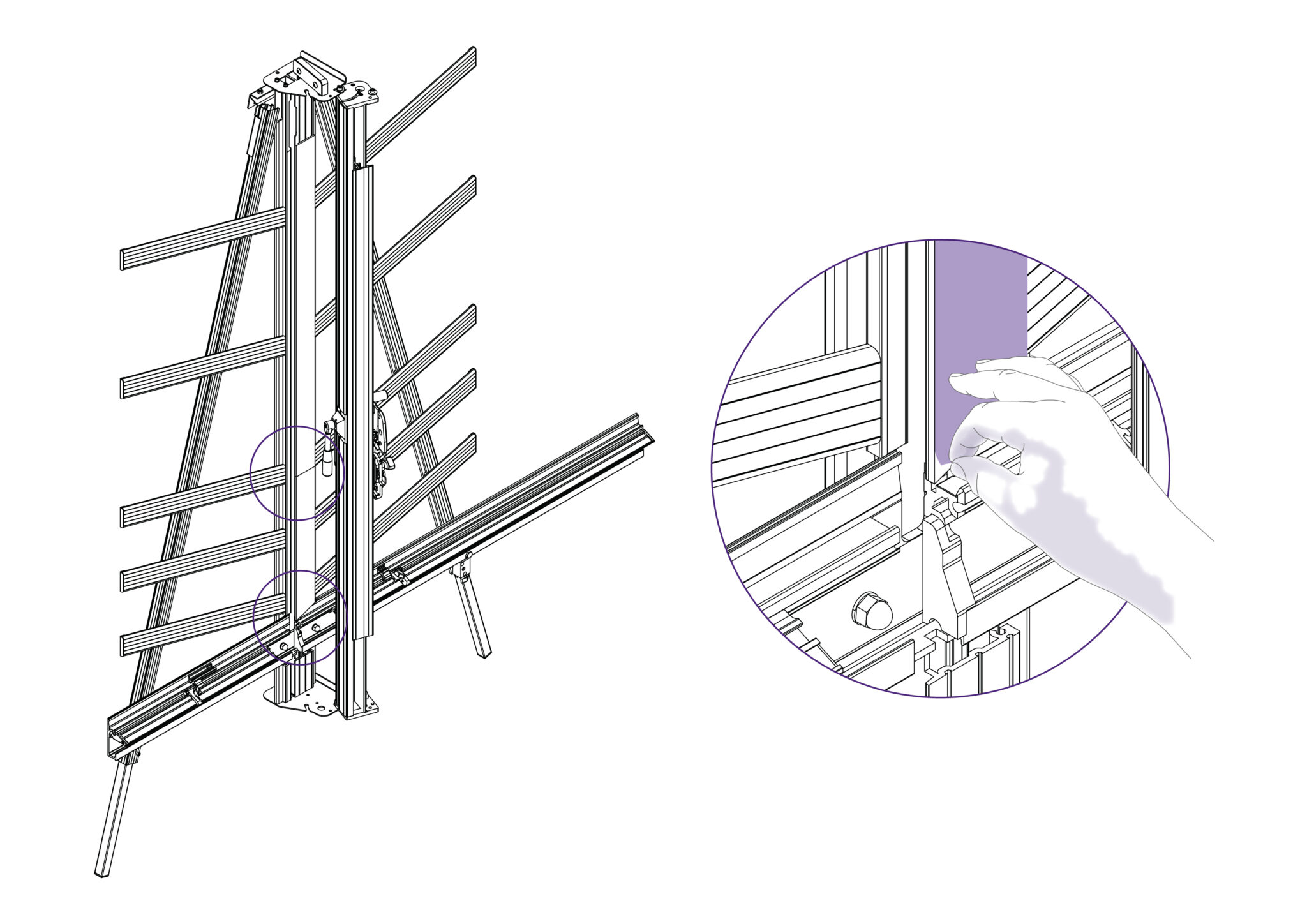

- Loosen the two screws using the 6mm Allen key (hex key) on the mount plate of the machine, as indicated.

- The left hand one needs to be undone enough for the flanged washer (A) to be lifted clear of the top plate, or it can be entirely removed if you prefer but do not remove the other screw.

- Repeat this at the bottom end of the machine.

- With the blue support board now accessible, slightly remove the edge away using a thin and rigid item such as a ruler. Peel the layers of double sided tape from the main body if any tape remains on the surfaces.

- Clean the surface of the main body with white spirit to clear any remnants of adhesive.

- Follow through with the same steps for the other blue support board on the main body.

- Ensure any remnant of cleaning spirit is dried off before proceeding to place the new blue support boards onto the main body.

Placing onto the main body:

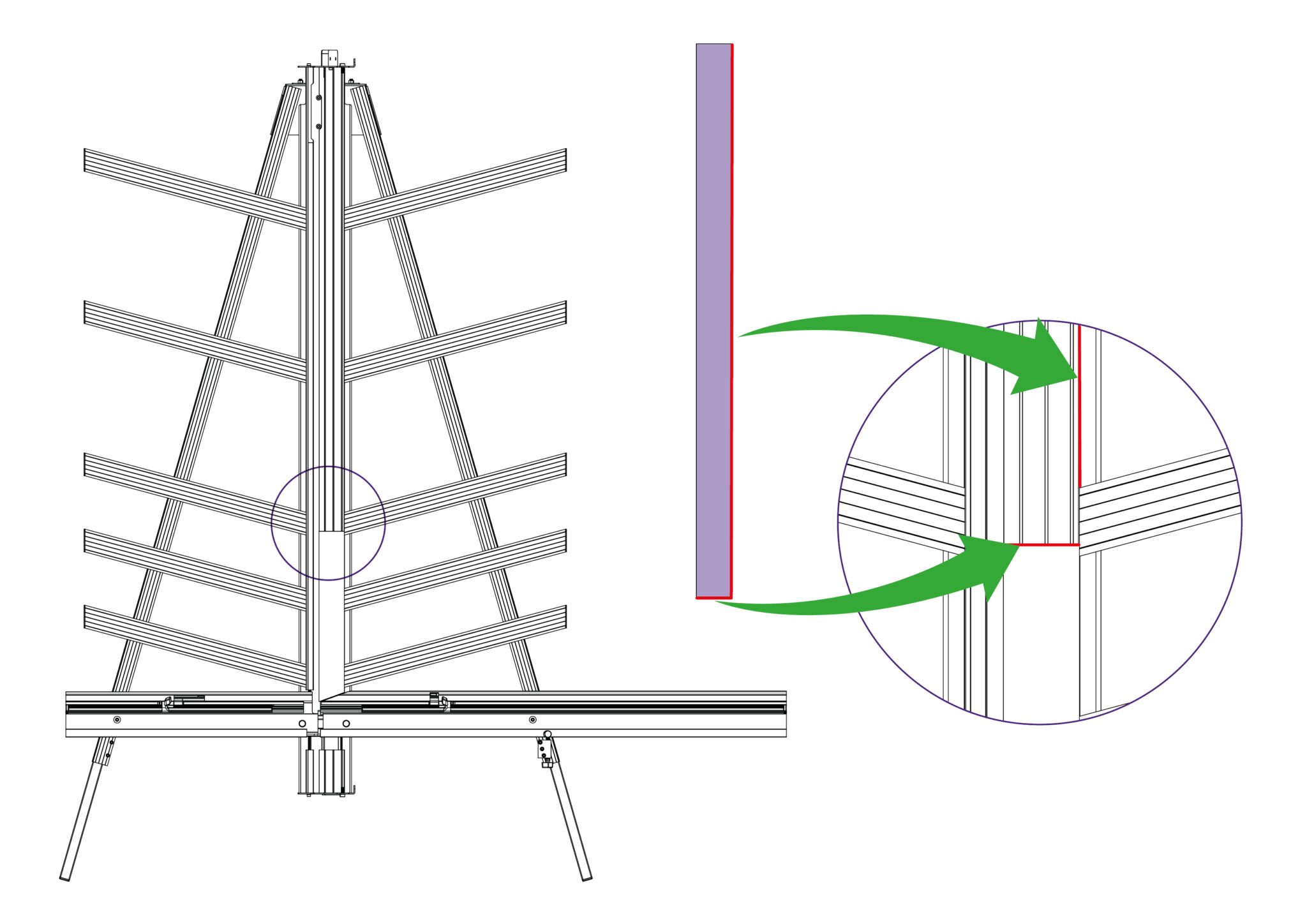

- Peel the release paper off the double sided tape and align the angled face of the lower board with the angled face of the main body.

- Ensure that the straight face identified is aligned with the face of the main body and that it does not overlap on to the support arms.

- Proceed to lower the lower blue support board onto the main body, starting from the aligned edges.