Blade not running in the base plate groove on Sabre Series 2

Before you start

Before starting any work, check that you have the following equipment:

- A strong thin wire like nylon fishing line

1. The Sabre Series 2 MUST be placed on flat table surface

It is essential that the Sabre Series 2 is placed on a flat table surface when being used.

If the surface is not flat, the base can follow the bend in the table and the cutter bar will follow that. Then, when the cutting head is pressed down the cutter bar can bend sideways, causing the blade to miss the groove.

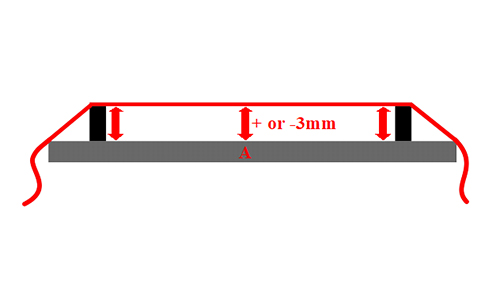

The flatness of the surface (A) can be checked by stretching a strong thin thread on two equal height blocks across the surface where the machine sits. The surface should be within 3mm (3/32″) flat. If the surface is found to be outside this tolerance spacers can be placed under the base to compensate.

2. Make sure cutter bar is supported along the full length by the material

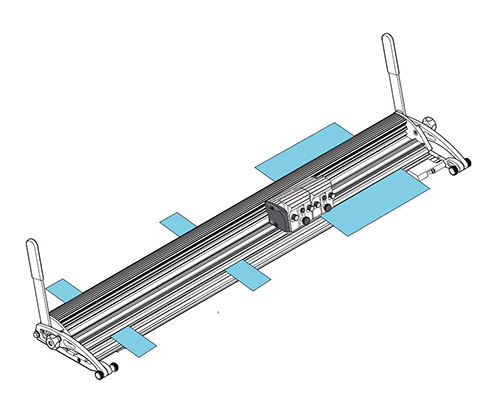

Another reason a blade may not run in the cutting groove is when short pieces of board are cut in the middle of the cutter bar. This will produce a downward bend in the cutter bar, as the ends of the cutter hang off of the edges of the board. This has the same effect as above and bends the cutter bar sideways in the middle, so the blade comes out of the groove in the base.

When cutting small pieces, place the board at one end of the cutter and a small scrap piece of the same board, or one of the same thickness, at the other end in order to support the cutter bar and keep it flat. The adjoining picture demonstrates the same principle on an Evolution E-2 cutter bar.

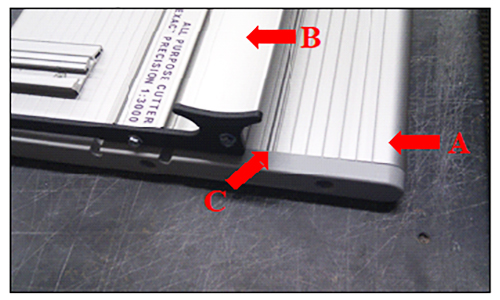

3. Finally check your base plate is running straight

Go to the following guide: Checking the Sabre S2 base plate straightness >