Medium duty utility blades

A double ground edged, reversible blade suitable for cutting all types of materials

Product information >

Align, clamp and push the button! Ultra-precise alignment in seconds using the sightline strip and Keencut clamping system. Once clamped, set the dial to the material you are cutting and pull the lever.

With its compact design, the PowerTrak is practical for any-sized workplace. Height-adjustable legs and wheels allow the PowerTrak to be positioned optimally for your workflow – it’s completely flexible! And, as it cuts without dust or debris, it can be placed next to your printer.

Pull-out support arms hold the material. Just pull out the arms, place your material into the machine, and if you want to cut a series of identical boards, set the arm stops. You can buy optional arms for the back of the machine.

1.30 hours to install, 15 minutes to master. It’s out of the box calibrated and ready to go! Just add a compressor or fit to your air line. You only need one operator with no specialist skills.

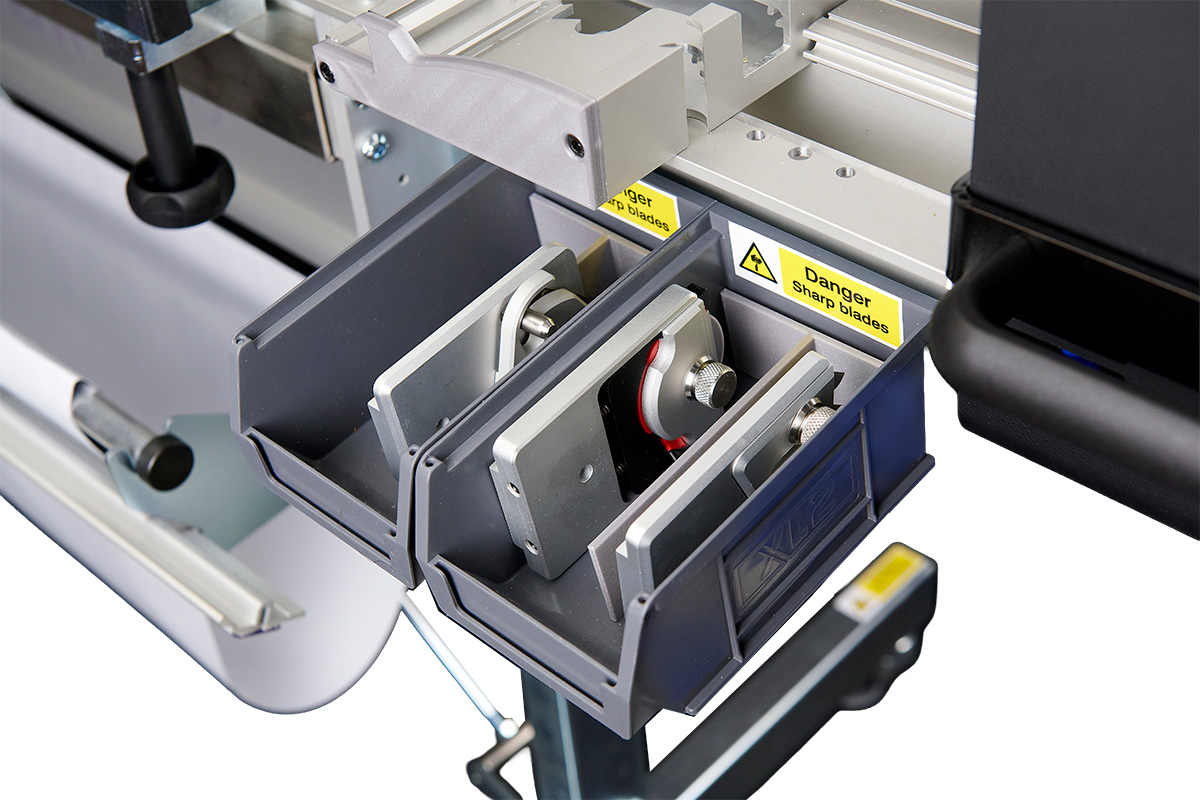

Operator safety is paramount, and the PowerTrak will not operate until the protective guard is in position. There is also an emergency stop button next to the operator controls.

Every feature is for easy and speedy operation. The easy-empty waste catcher lifts off to slide materials into a bin. The cutting heads sit in caddies on the machine, and a fabric bar is immediately to hand to insert for fabric cutting.

All this and Keencut’s acclaimed manufacturing reliability. The PowerTrak is manufactured in the Keencut UK facility using high-quality components and has a 5-year warranty.

C4 Quad Wheel Cutter (QWC) for ACM

Triple Graphic Pod for PVC foamboard

Medium Duty Pod for Foam centred board, Corrugated/ fluted plastic, Corrugated Cardboard, Mountboard

Rotary Pod for banners, vinyl, film, textiles and delicate materials

Acrylic Pod scoring Cast Acrylic/Plexiglass for snapping

V-Groover for V-grooving ACM

Like all Keencut machines, the PowerTrak is built to give many years of excellent service. All components are manufactured in-house to ensure quality and all PowerTrak cutters come with a five-year comprehensive guarantee. Register your product to activate your guarantee >

100 medium duty utility blades

100 graphik blades

1 45mm circular blade

1 3mm V groove tool

Rigid materials

Aluminium composite panel e.g Dibond ≤ 4mm (1/8″)Steel composite panel e.g Multishield ≤ 3mm (3/32″)

V-grooves ACM e.g Dibond ≤ 6mm (1/4″)

MDF ≤ 3mm (3/32″)

Cast acrylic / Plexiglas (scoring only) ≤ 3mm (3/32″)

Flexible materials

Banner

Vinyl

Film

Magbetic sheet

Textiles

Leather

Wallpaper

Paper

Self-adhesive vinyl

Tuissue paper

Delicate fabrics

Semi-rigid materials

PVC foamboard ≤ 13mm (1/2″)

Corrugated/fluted plastic ≤ 13mm (1/2″)

Corrugated cardboard ≤ 13mm (1/2″)

Foam centred board ≤ 13mm (1/2″)

Mountboard ≤ 6mm (1/4″)

A double ground edged, reversible blade suitable for cutting all types of materials

Product information >

Identify the spare parts , accessories and consumables for your machine.

Do you require further information on this product?