Excalibur 3S user guide – Maintenance

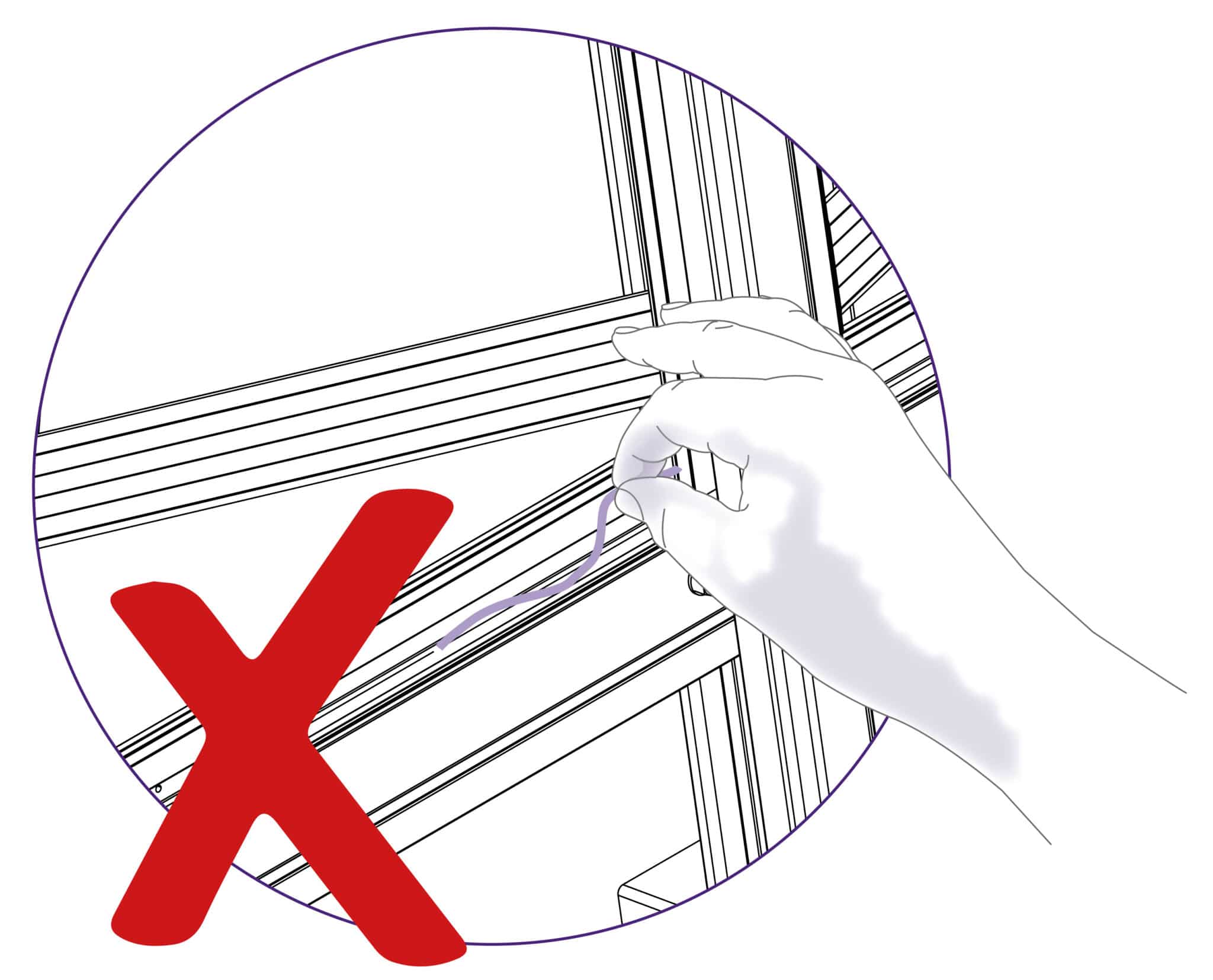

Do not wipe the squaring arm channels or remove any debris with fingers, as it may contain sharp particles such as glass.

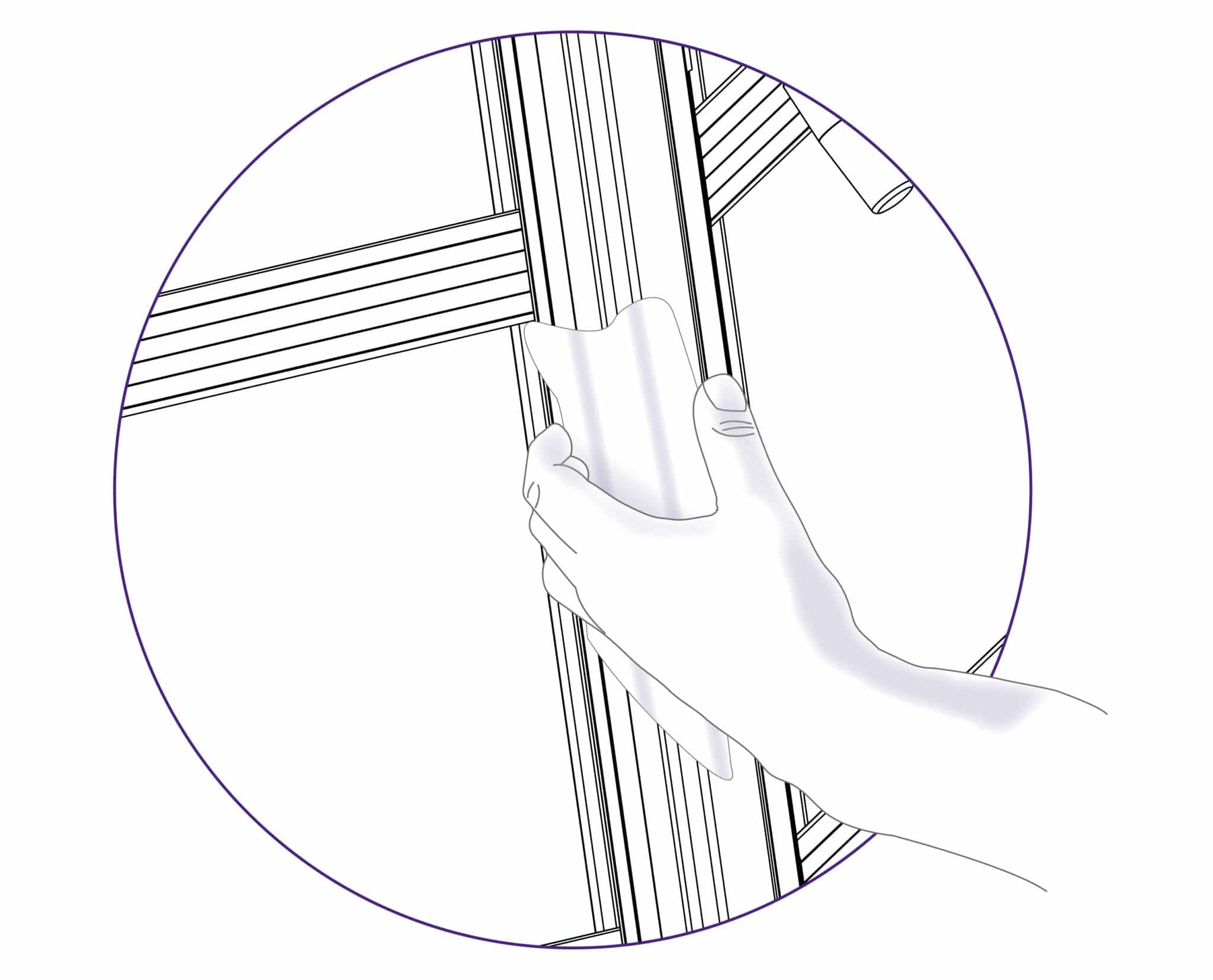

Use a vacuum cleaner if possible or if a soft brush is used, work slowly and do not allow particles to flick off the bristles.

The slideway can be cleaned and lubricated occasionally using a silicone lubricant. Removing any excess with a cloth.

The multi cutter assembly may require dusting out periodically do not lubricate or adjust without seeking further advice from your distributor or Keencut.

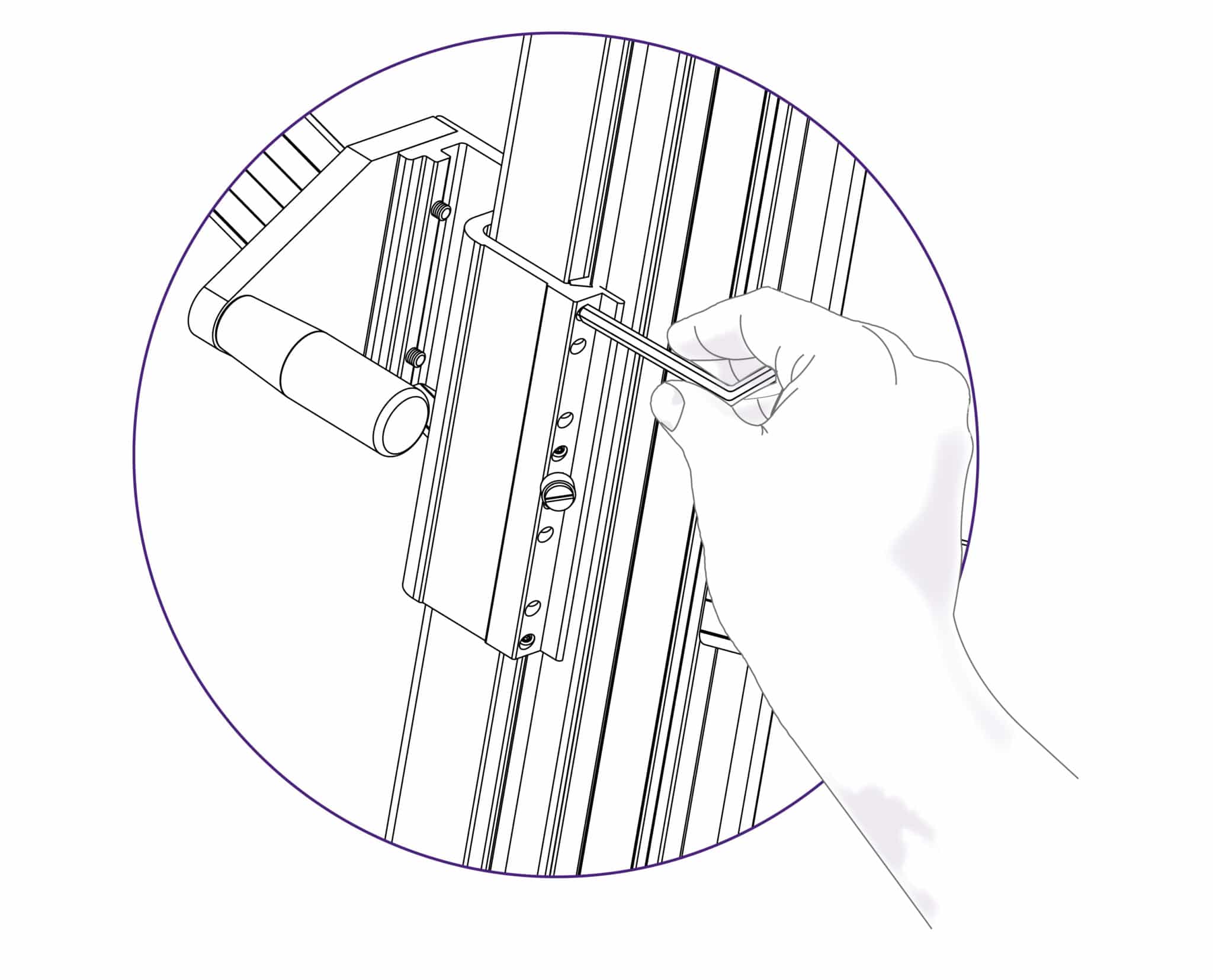

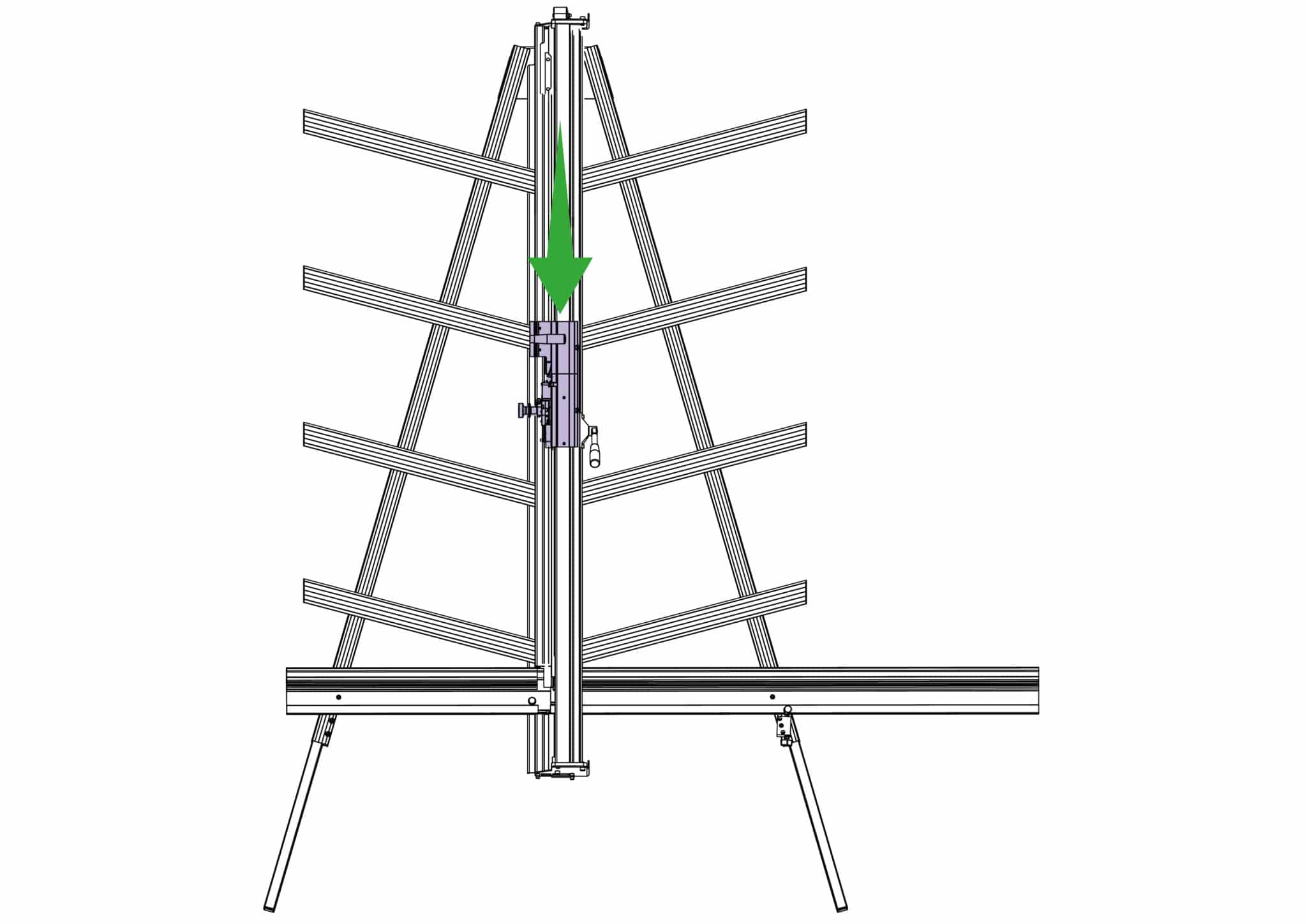

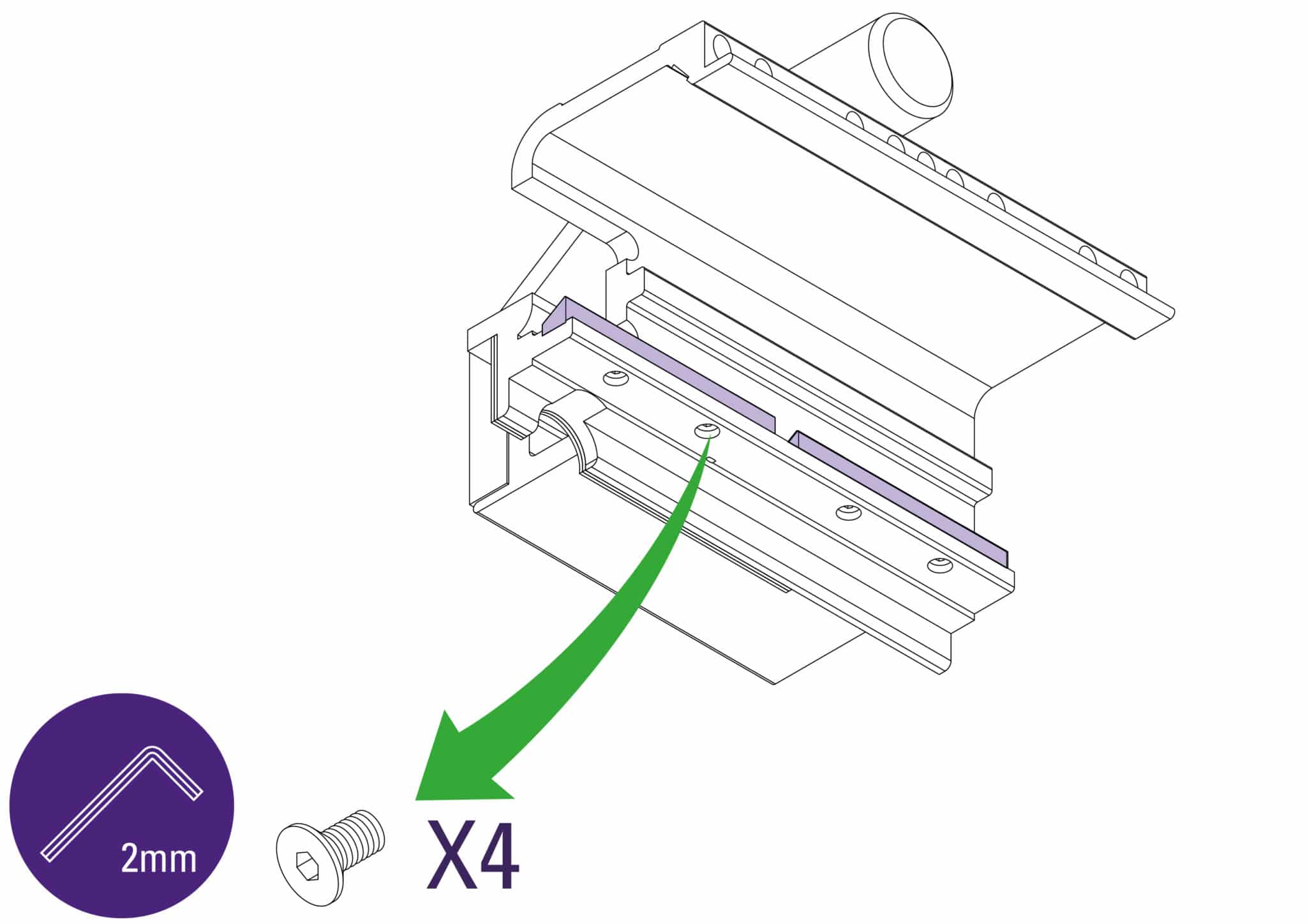

Attach the balance weight (see The multi-tool cutter and the counterbalance >) to the other cutting head, hold the cutter at waist height and place a 2mm hexagon wrench on the top adjustment screw.

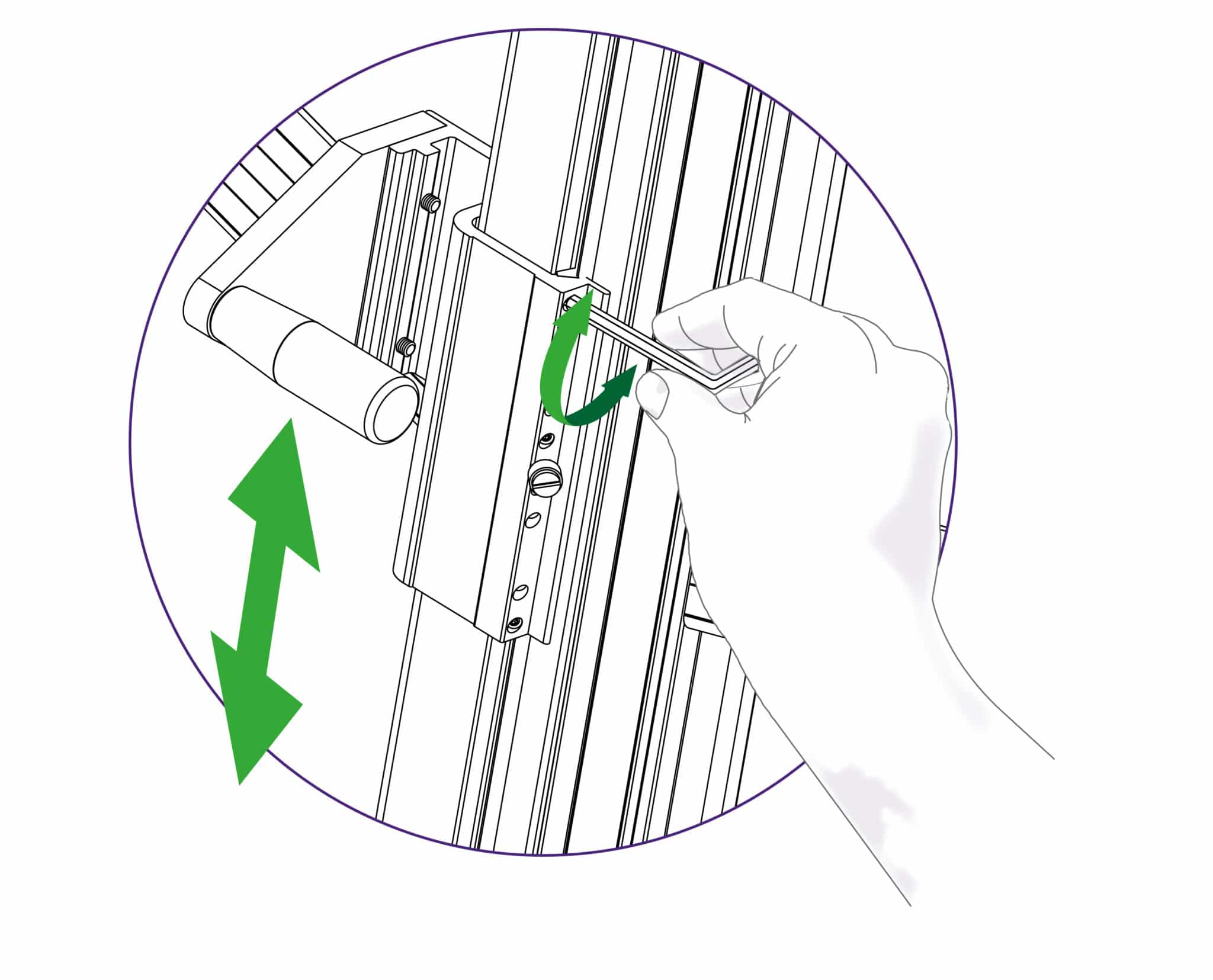

Move the cutting head up and down and tighten the screw very gradually until the cutting head does not fall under its own weight.

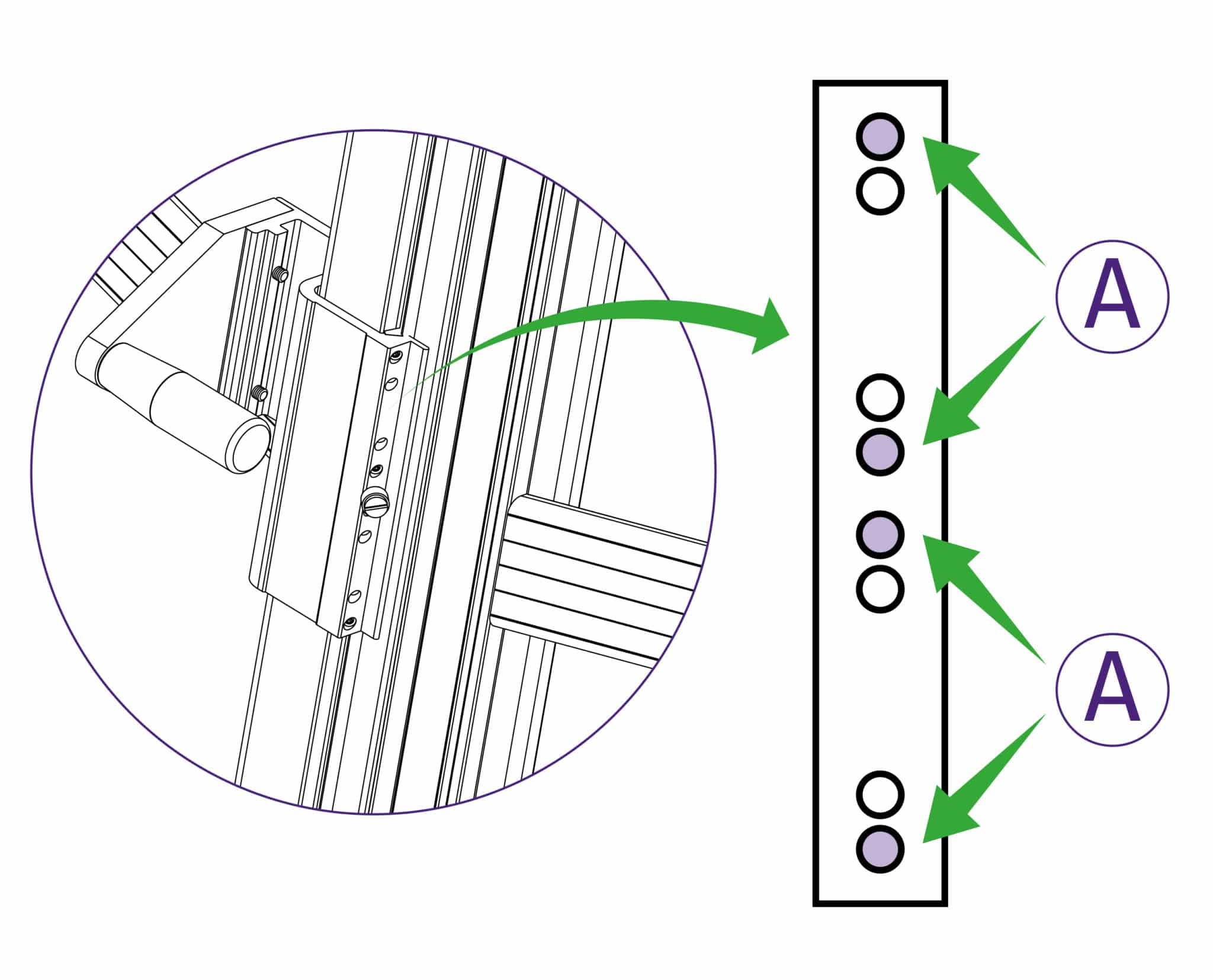

Loosen the screw by the smallest amount you can until it does fall under its own weight. Repeat the process with the other three adjustment screws (A).

Move the head to a comfortable height.

Apply the balance weight to the lower head.

Tighten the white screw on the upper head.

Move the lower head away from the upper head.

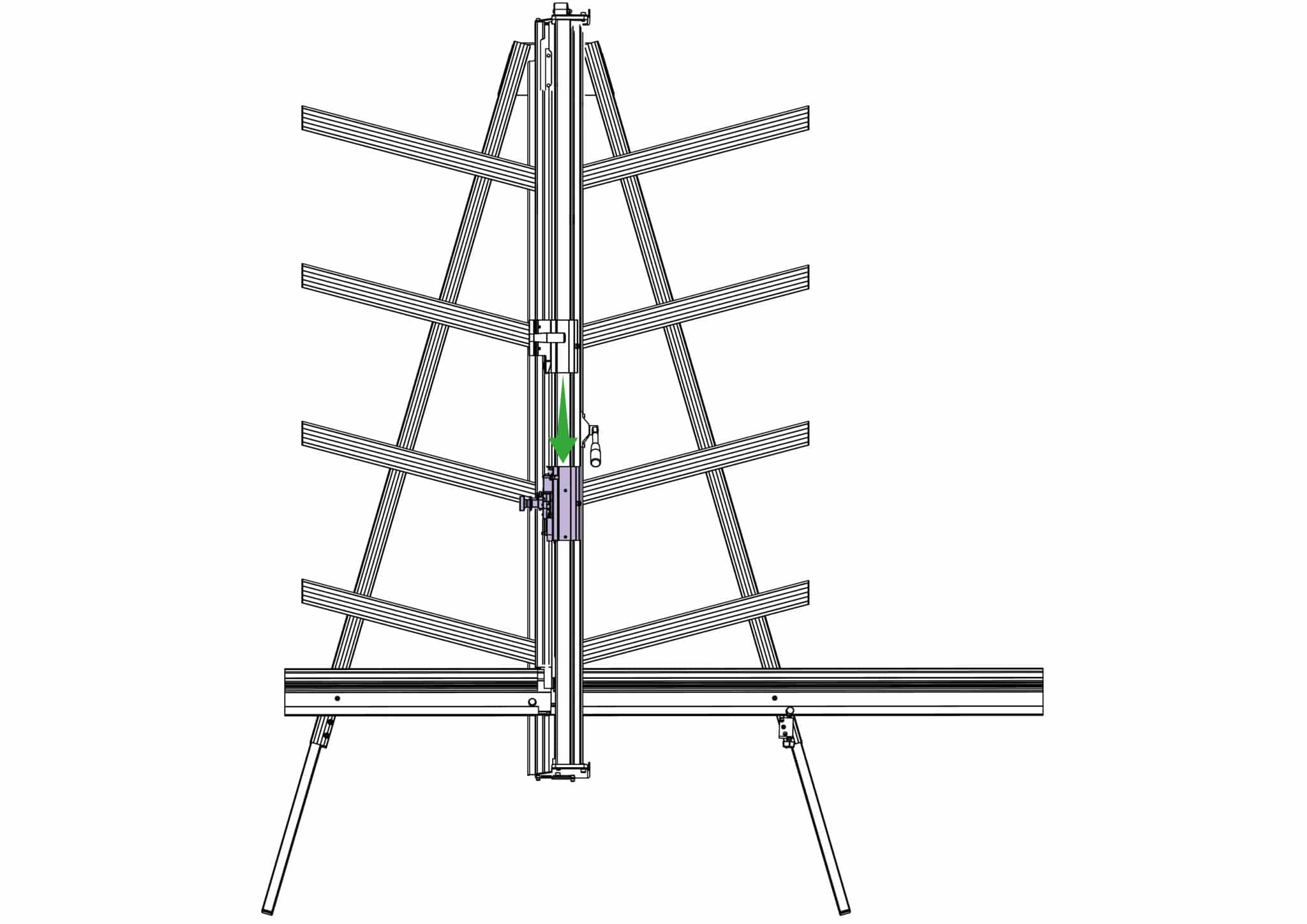

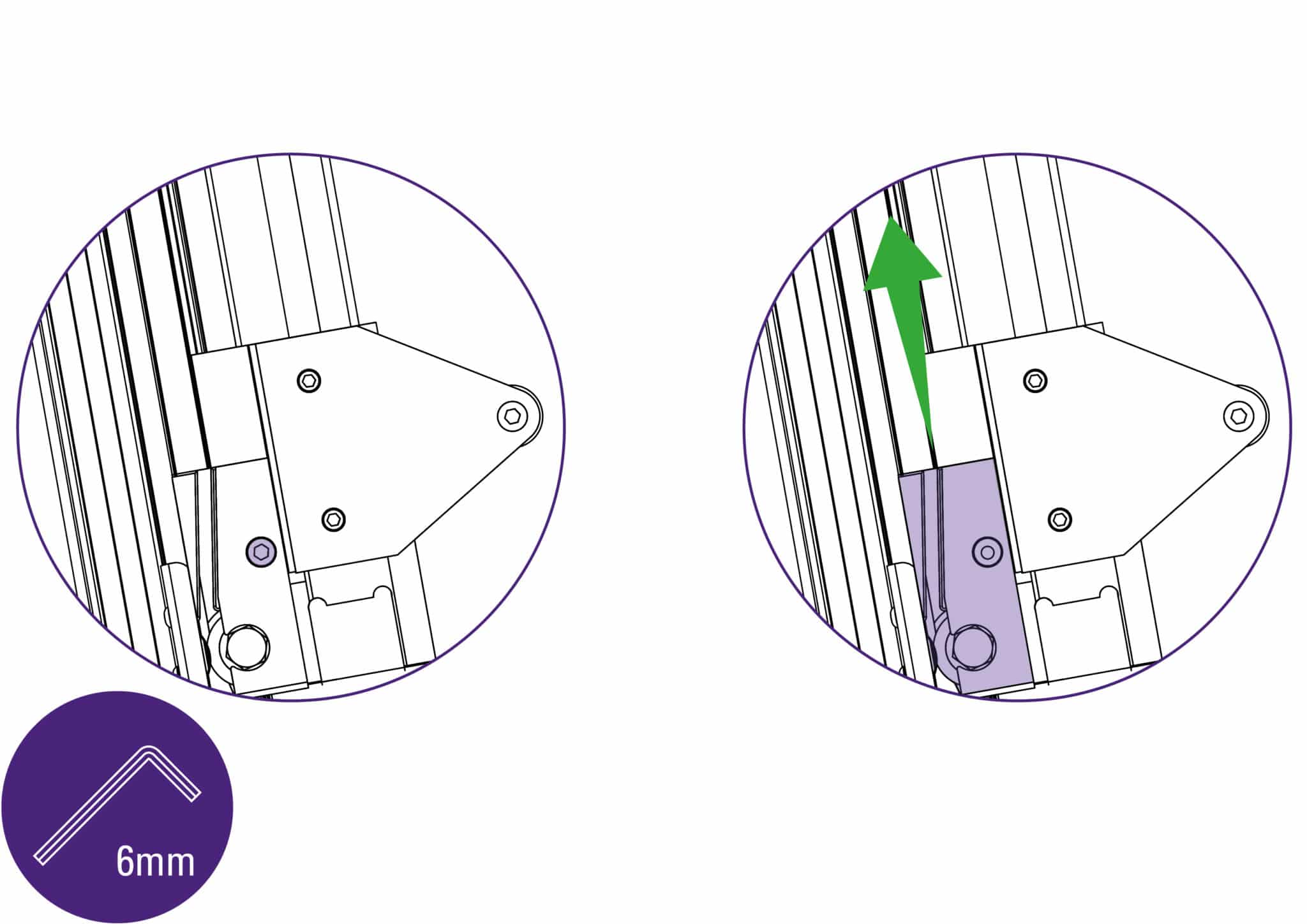

Use a 6mm Allen (hex) key to remove the screw holding the twin wheel cutter in place. Slide it up to the top of the machine and remove.

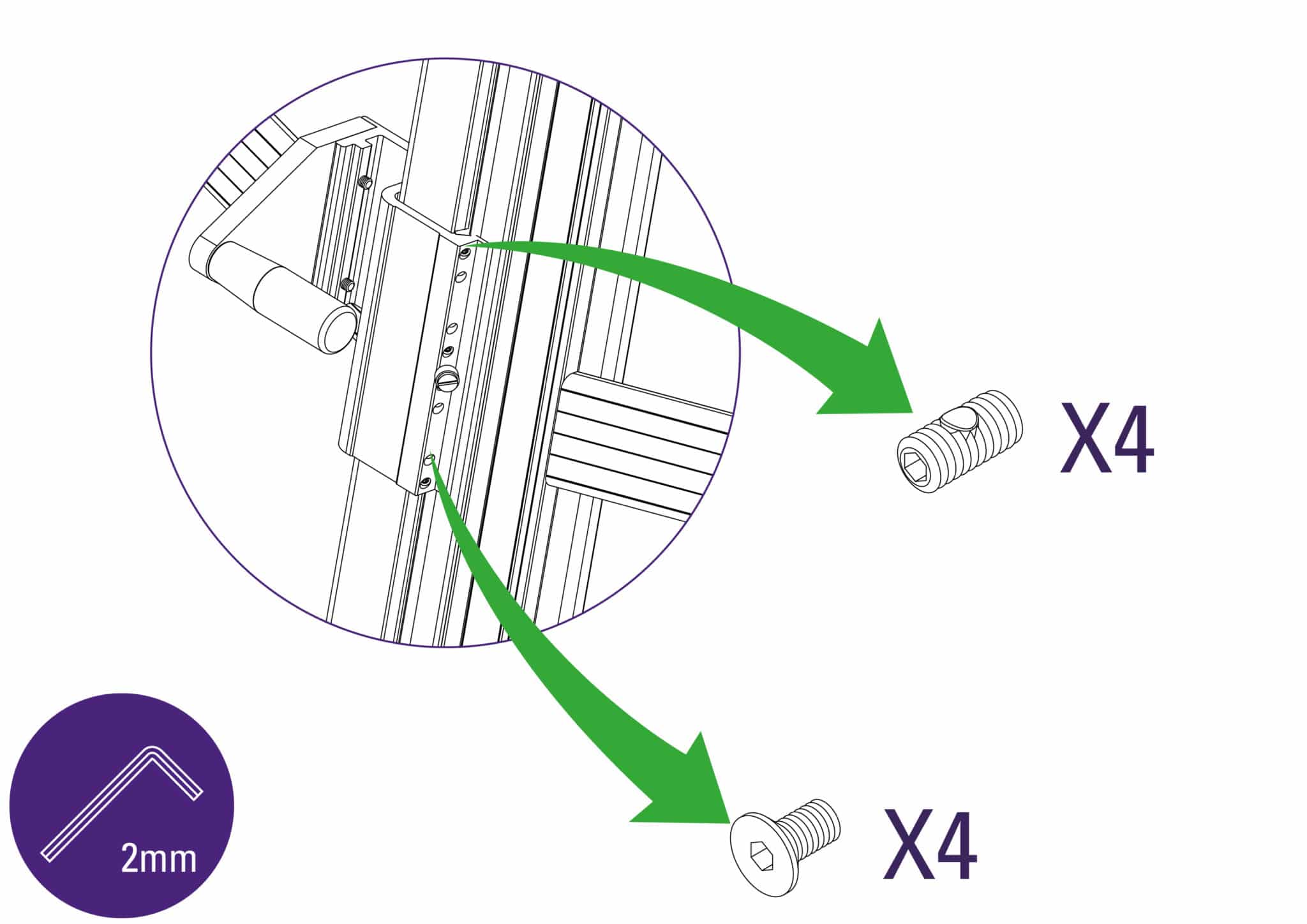

Use a 2mm Allen (Hex) key to remove all 8 screws from the handle.

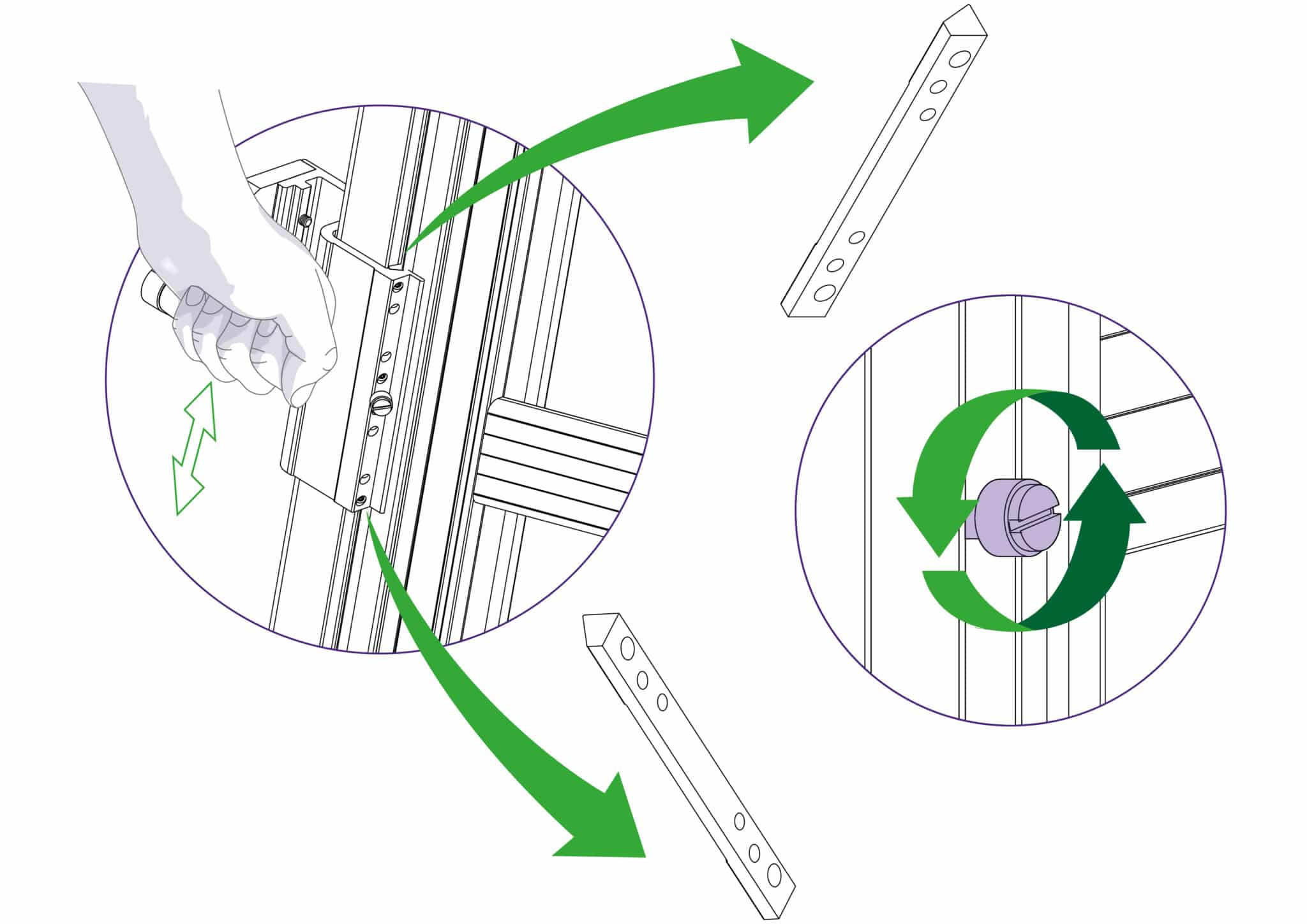

Hold onto the handle, remove the white screw, and move the head up and down carefully. The two bearing blocks should drop out.

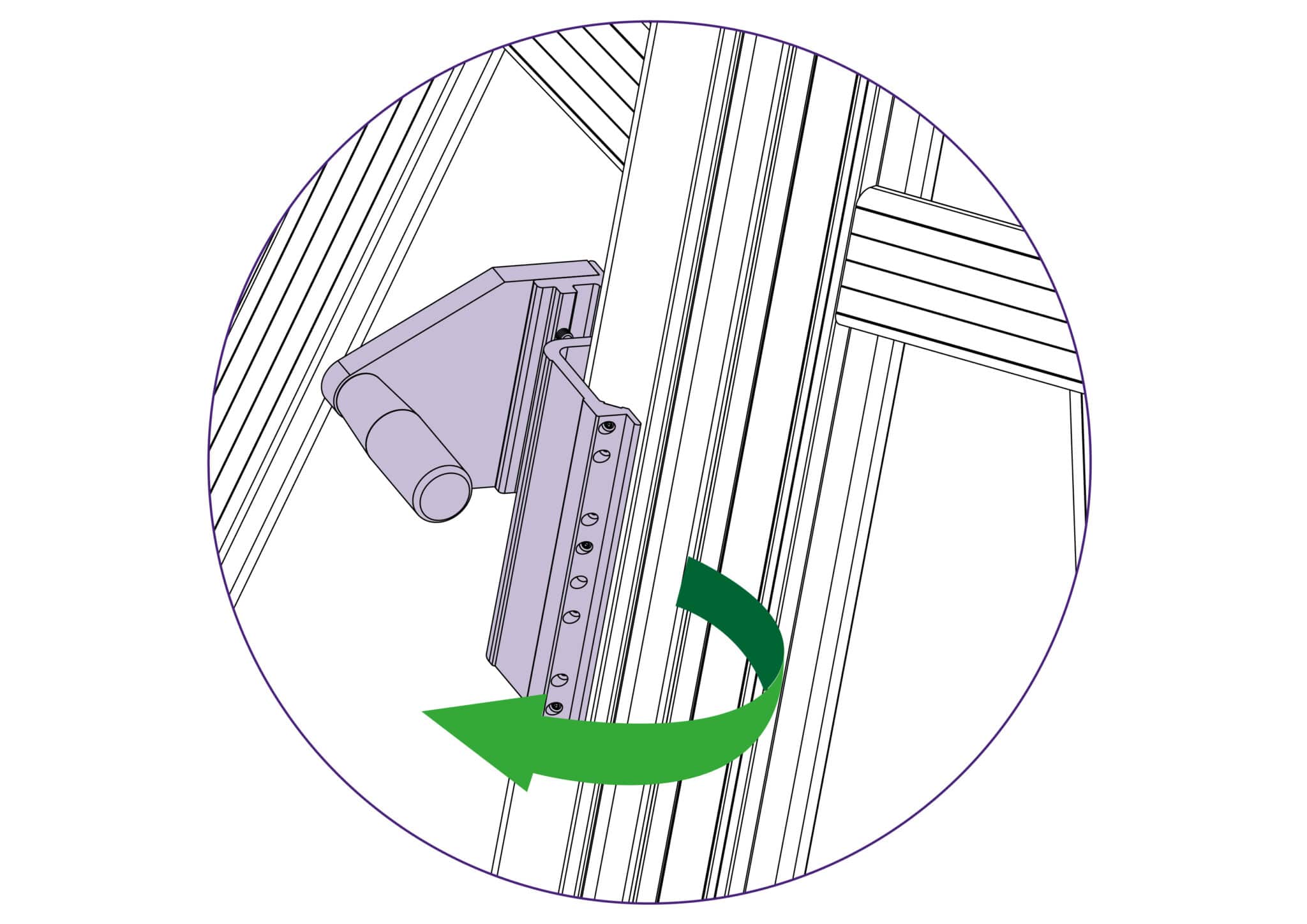

Rotate the head until it comes loose from the machine.

Use a 2mm Allen (Hex) key to remove the screws holding the internal bearings in place.

Reverse these steps to re-install. Refer to Adjusting the sliding bearings> to adjust the sliding fit.

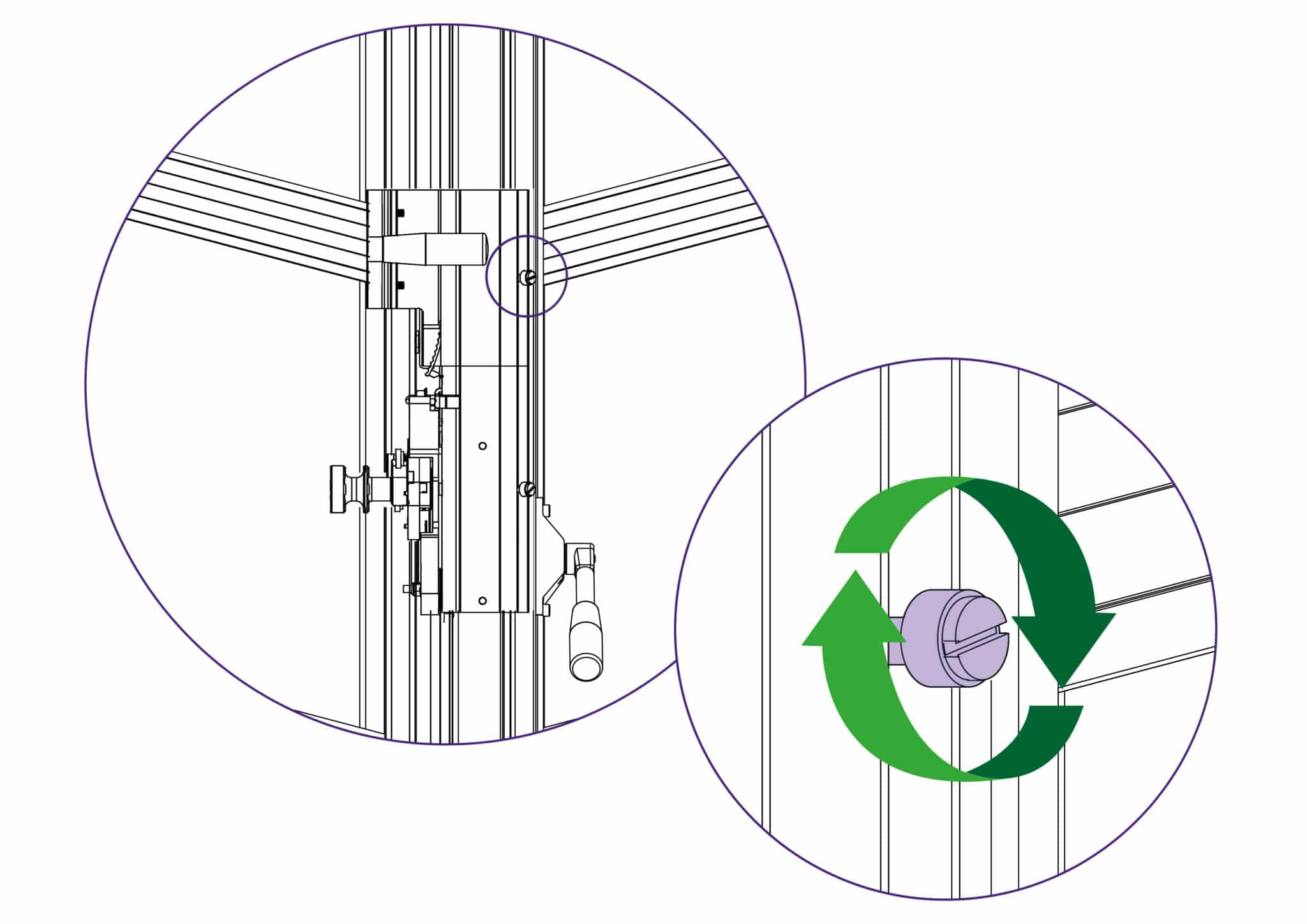

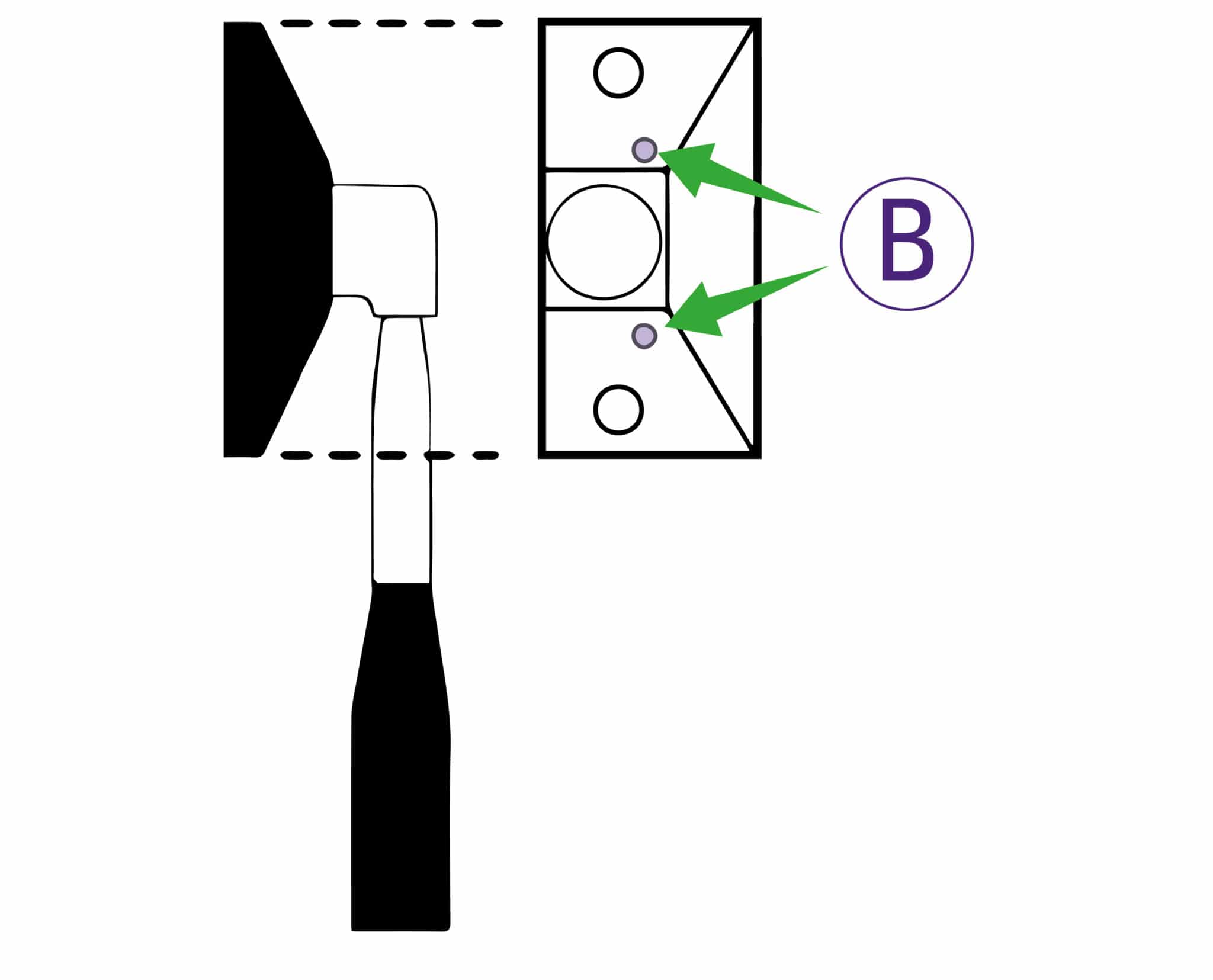

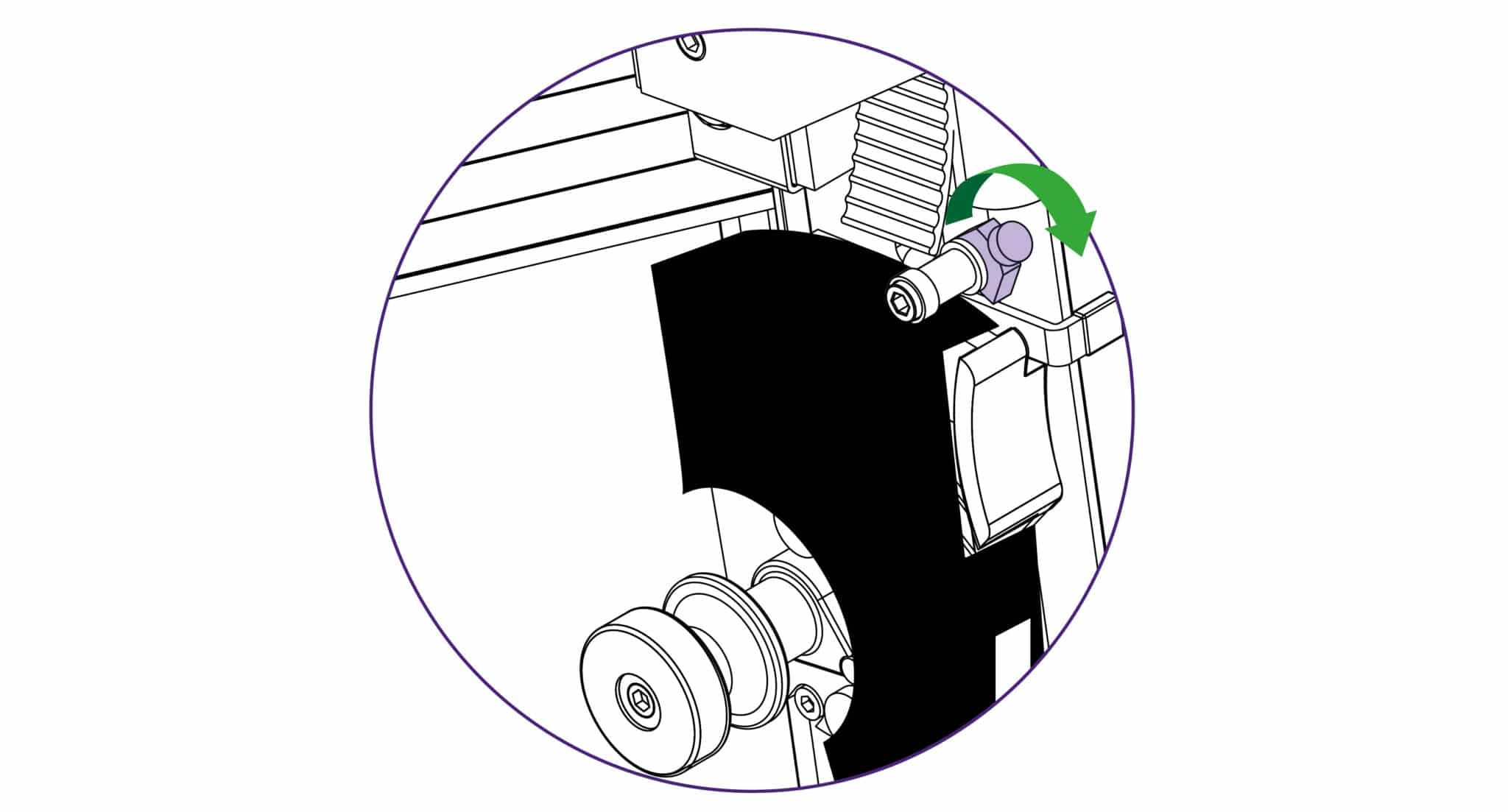

The pressure of the clamp is in relation to the amount of pressure applied to the operating handle. However in time the maximum clamping pressure can reduce due to wear on the friction black (hidden within the machine), compensation for this can be made by adjusting the two small grub screws in the operating handle housing as shown. Turning the screws clockwise will increase the maximum clamping pressure.

Turn both screws all the way in and then undo by a quarter of a turn, slight adjustment can be made to fine tune the pressure. Do not operate the clamp with the adjustment screws tight.

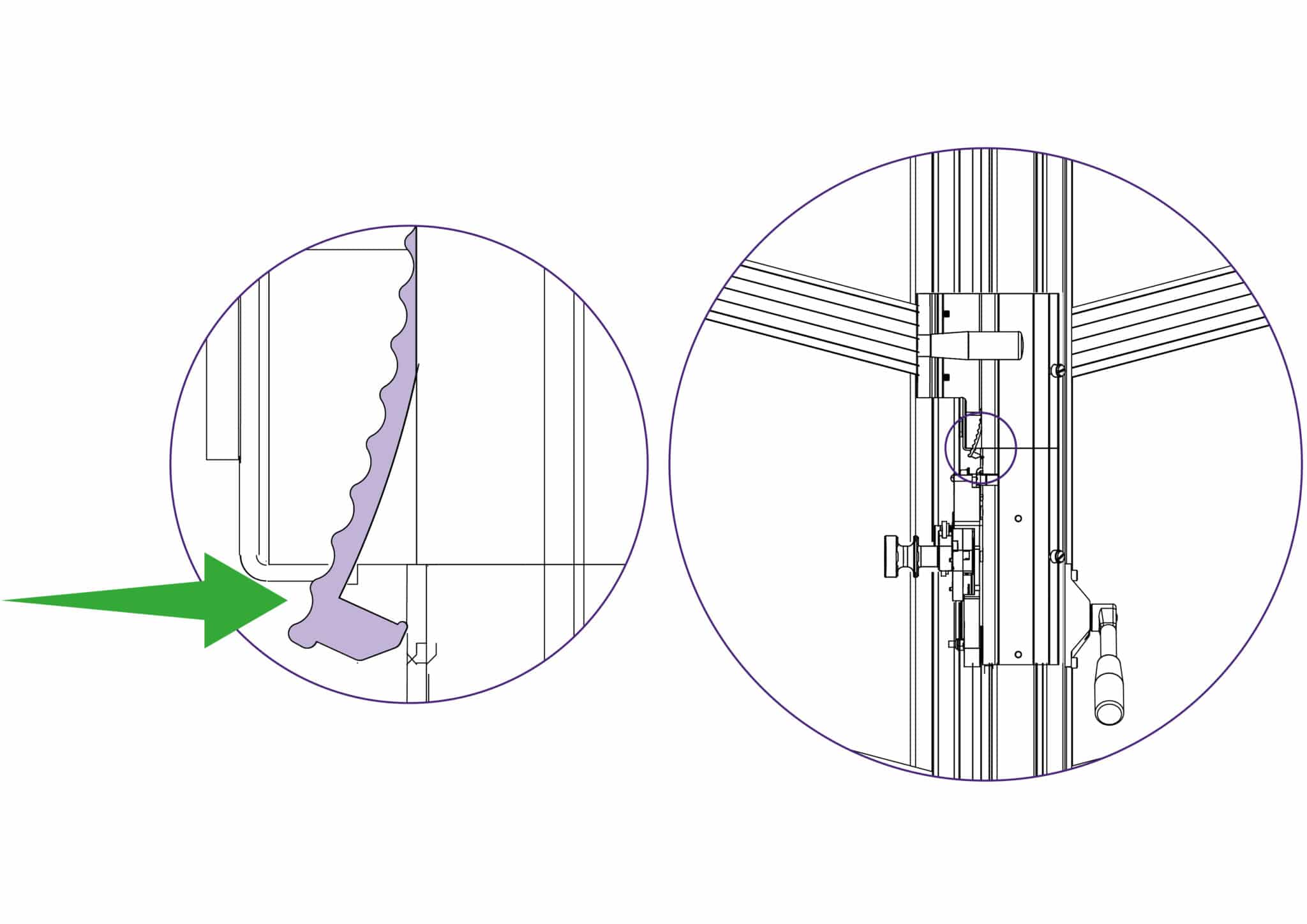

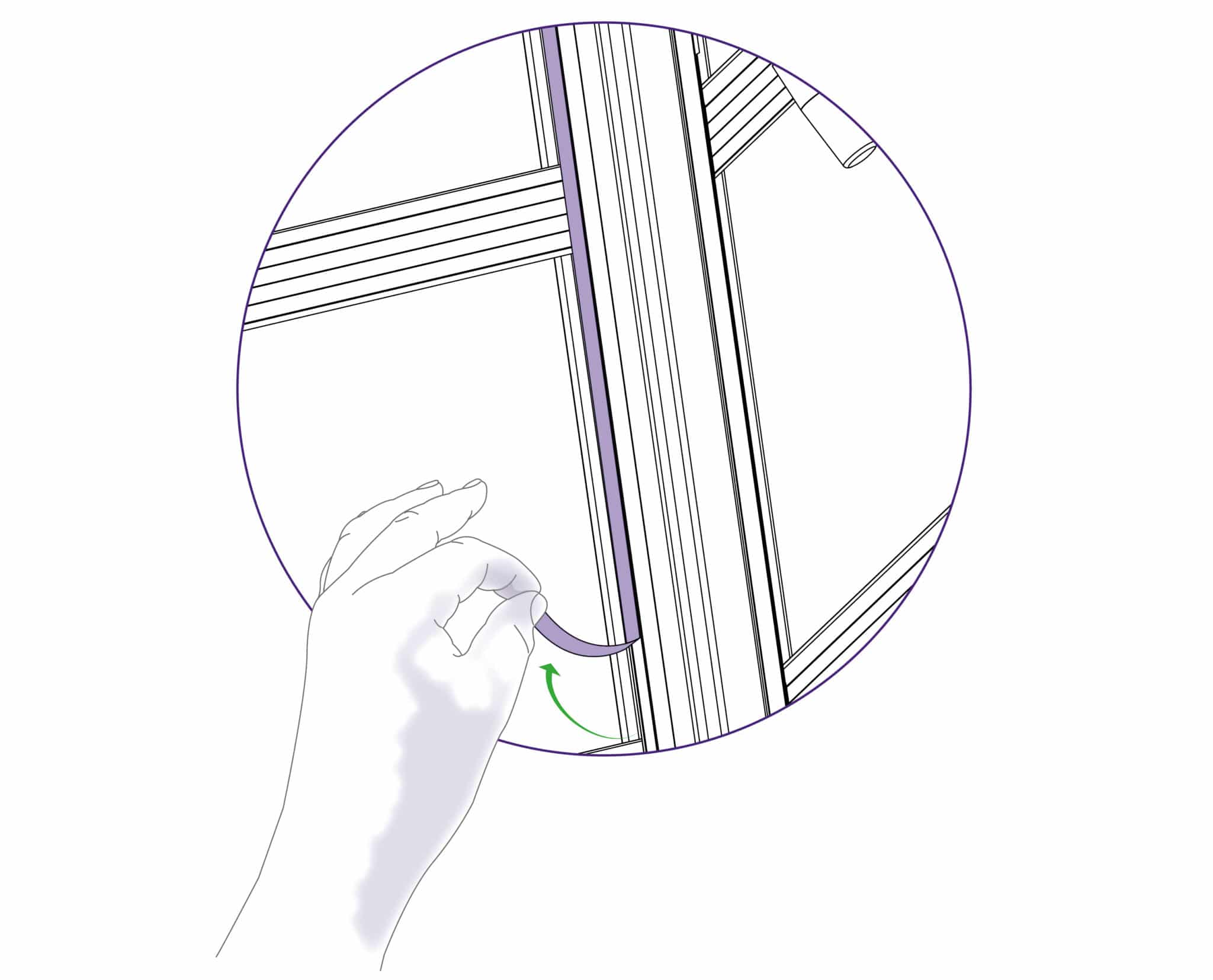

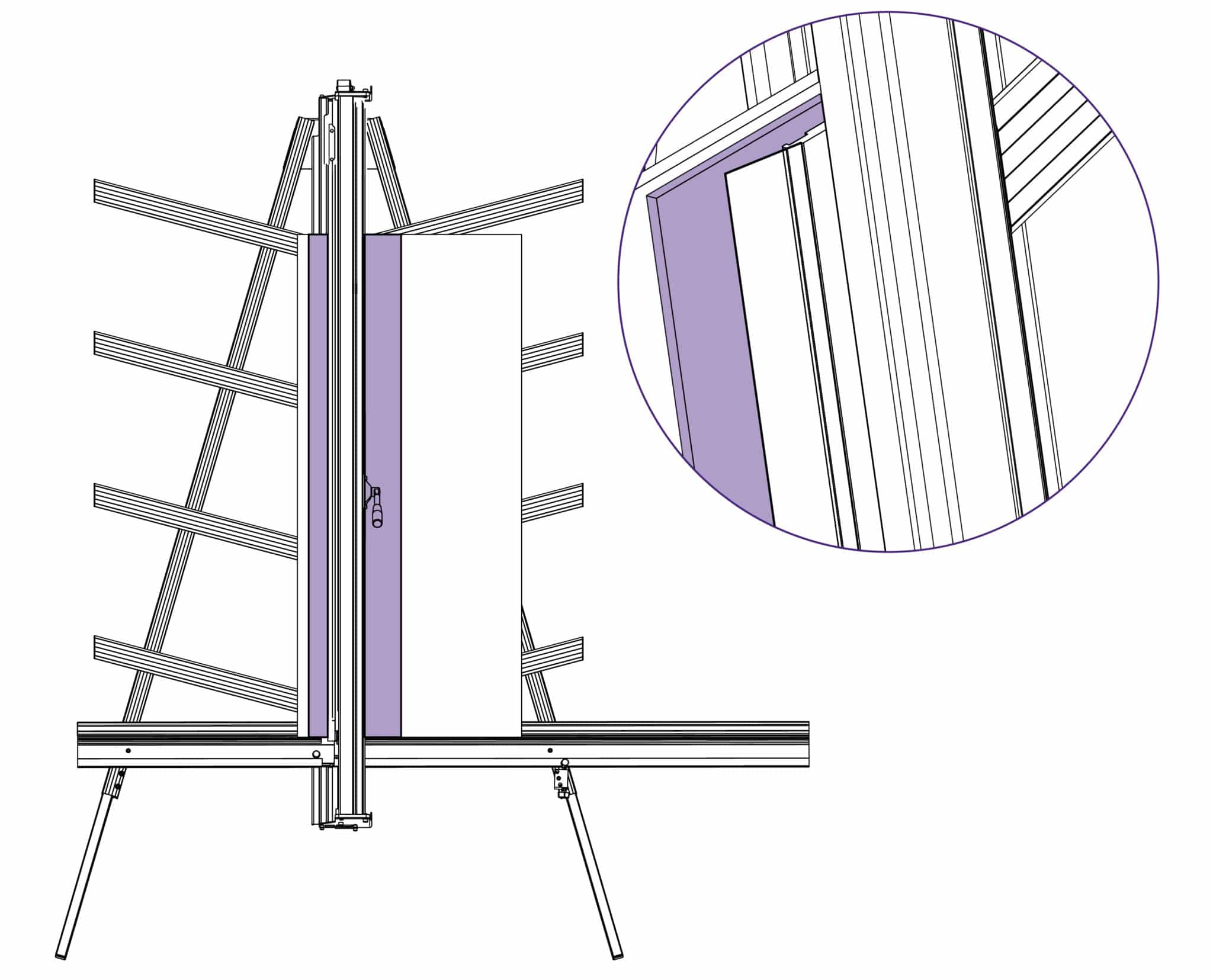

The sightline strip is fixed to the clamp and then trimmed using the cutting blade to give an accurate guide when cutting to trim lines, the edge of an image or pencil marks.

NOTE: Do not engage the twin wheel cutter until after reading its instructions for use in Using & changing the twin wheel cutter>. Engaging the twin wheel cutter interferes with the sightline strip and can cause damage to it. A gap is left in the sightline strip at a convenient height to enable the twin wheel cutter to be engaged.

Remove the worn sightline strip by peeling it off and clean any surplus adhesive with solvent cleaner on a cloth. Remove the backing paper and starting at the bottom press the strip firmly in the channel provided working upwards and cut off at a convenient height. Leave a gap of 18cm (7”) and then fit the remainder of the strip.

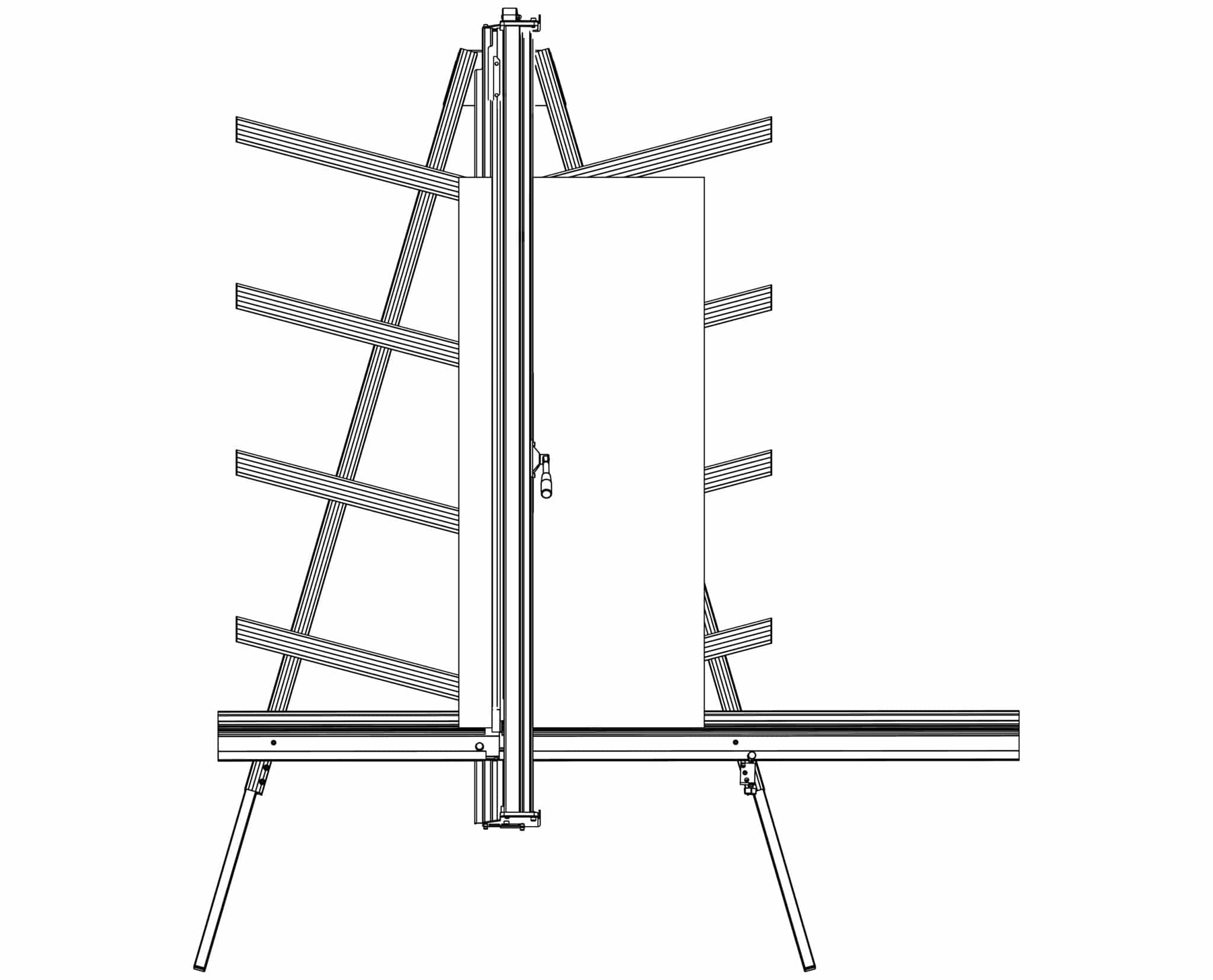

Place a piece of firm board up to 6mm (1/4”) thick on the machine to bridge the gap running down the back of the main body, this needs to be the full height of the clamp.

Place a piece of card or foam board 3-6mm (1/8”-1/4”) thick under the full length of the flexible part of the sightline strip, not under the aluminium clamp itself. Depress the clamp handle so that the sightline strip is pressed flat across the surface of the board.

Keep fingers clear and using a block or tool hold down the top left corner of the strip to start the cut. With the turret ratchet disengaged (see Using the scoring blade >) press the blade lightly on to the surface of the sightline strip and score along the full length. Repeat and trim the sightline strip in 2 or 3 cuts.

Do not wipe the squaring arm channels or remove any debris with fingers, as it may contain sharp particles such as glass.

Attach the balance weight (see The multi-tool cutter and the counterbalance >) to the other cutting head, hold the cutter at waist height and place a 2mm hexagon wrench on the top adjustment screw.

Move the cutting head up and down and tighten the screw very gradually until the cutting head does not fall under its own weight.

Use a 6mm Allen (hex) key to remove the screw holding the twin wheel cutter in place. Slide it up to the top of the machine and remove.

Hold onto the handle, remove the white screw, and move the head up and down carefully. The two bearing blocks should drop out.

Use a 2mm Allen (Hex) key to remove the screws holding the internal bearings in place.

Reverse these steps to re-install. Refer to Adjusting the sliding bearings> to adjust the sliding fit.

The pressure of the clamp is in relation to the amount of pressure applied to the operating handle. However in time the maximum clamping pressure can reduce due to wear on the friction black (hidden within the machine), compensation for this can be made by adjusting the two small grub screws in the operating handle housing as shown. Turning the screws clockwise will increase the maximum clamping pressure.