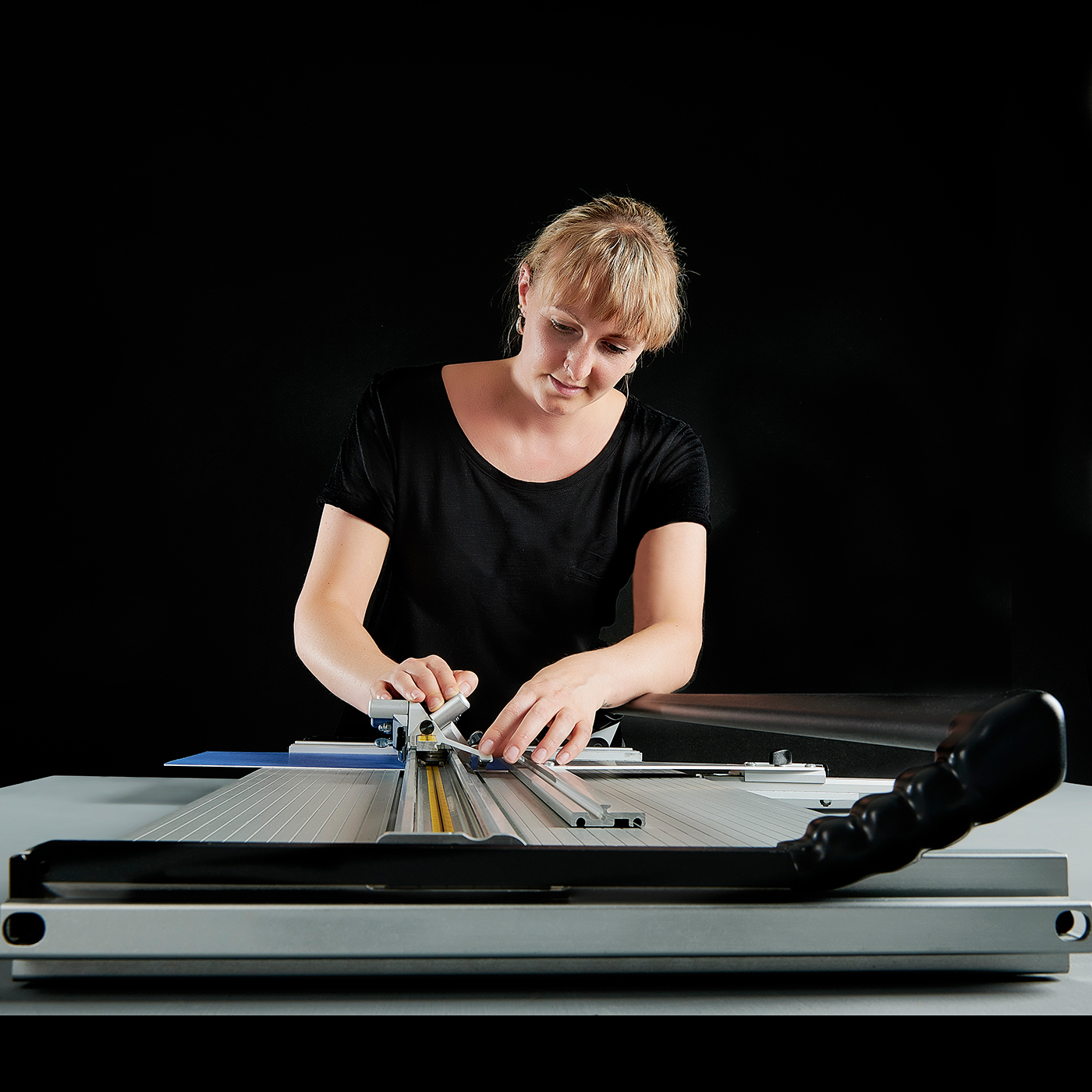

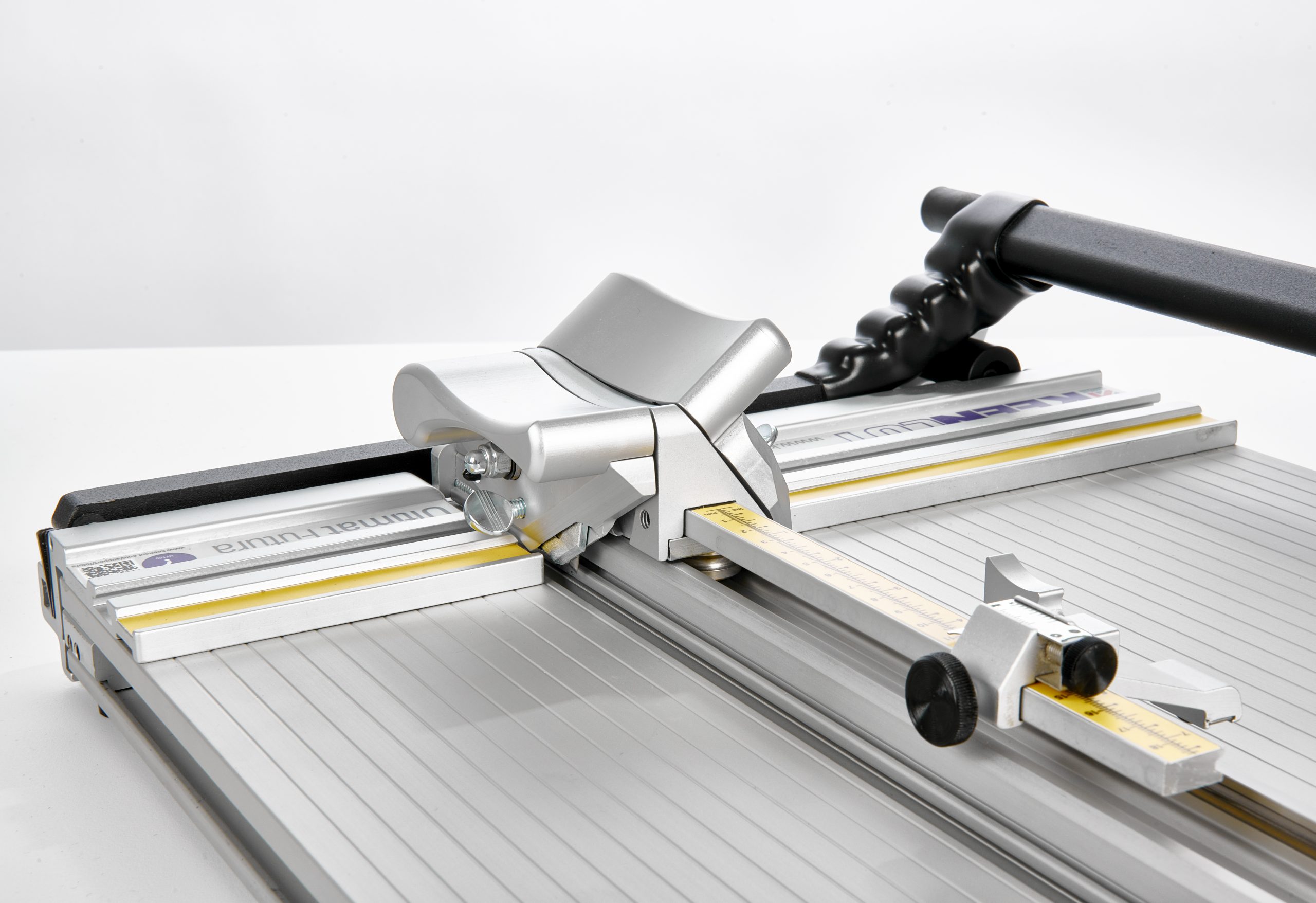

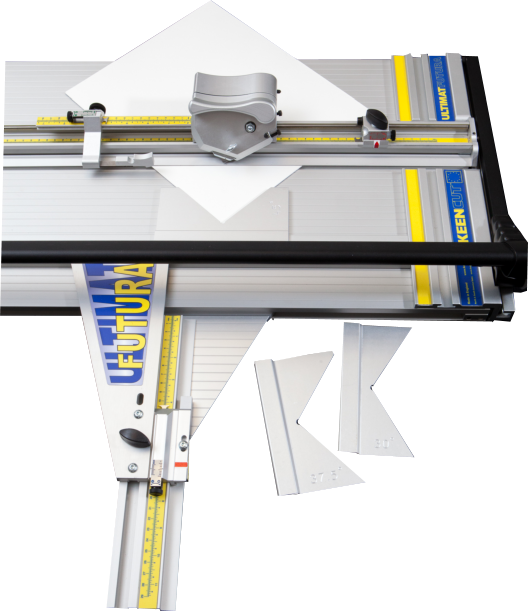

Ultimat Futura

Features

Consistent faultless mounts

The Ultimat Futura performs perfectly on even the thickest conservation mountboard. The blade cartridge system provides accurate blade depth control and a measuring stop ensures flawless v-grooves. Everything is squared and calibrated ready for you to use straight out of the box.

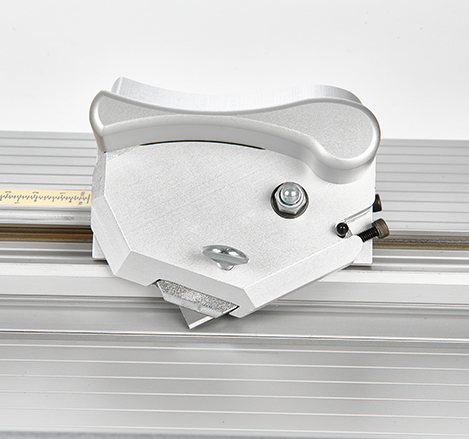

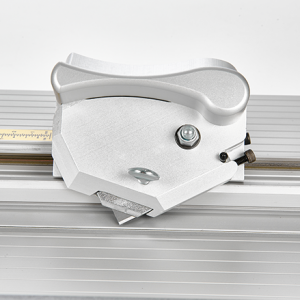

No more overcuts or undercuts

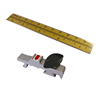

The micro stop adjusters fitted to the start of cut, end of cut and margin guide stops, allow you to dial out overcuts or undercuts in seconds. It’s so simple, any overcut is eliminated by turning the stop thumbscrew towards minus (-) and any undercut is eliminated by turning the thumbscrew towards plus (+). A rigid self-aligning margin guide ensures consistent accurate parallel borders.

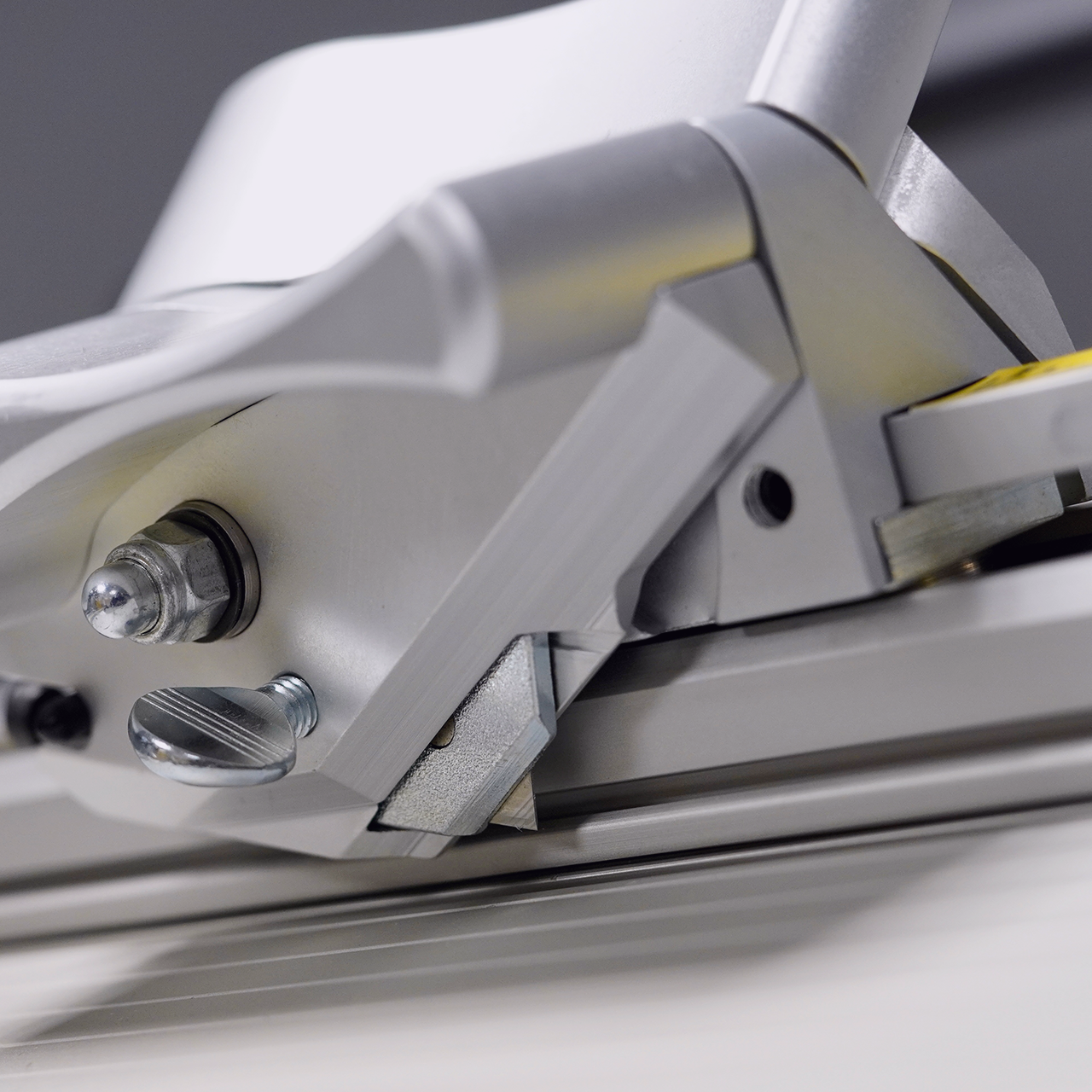

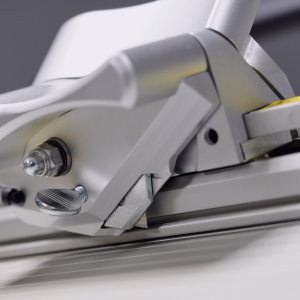

Unequalled blade control and effortless cutting

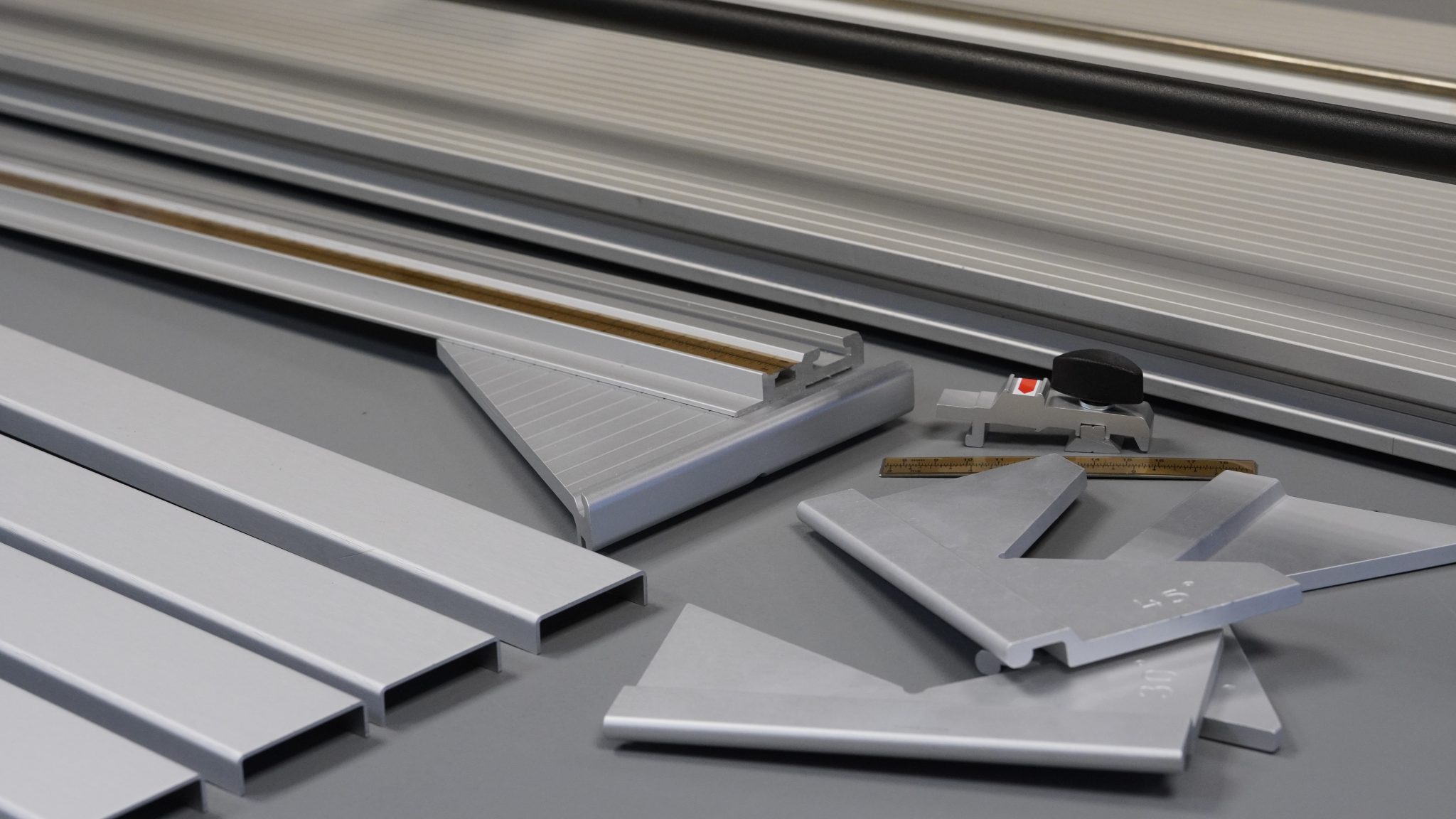

The Ultimat Futura cutting head has built-in self-adjusting ball bearing rollers operating on twin stainless-steel tracks, to deliver a sliding action that is smooth, precise and with no discernible friction. The blade holders are mounted on large thrust and radial bearings for precision blade control with zero side-play. The heavy-duty, one-piece aluminium extruded base gives absolute stability. Maximum operator effort is transmitted to the blade, to allow easy cutting of even the thickest boards.

Hands free

The unique roller lift and hold system frees your hands so that you can precisely position the mountboard.

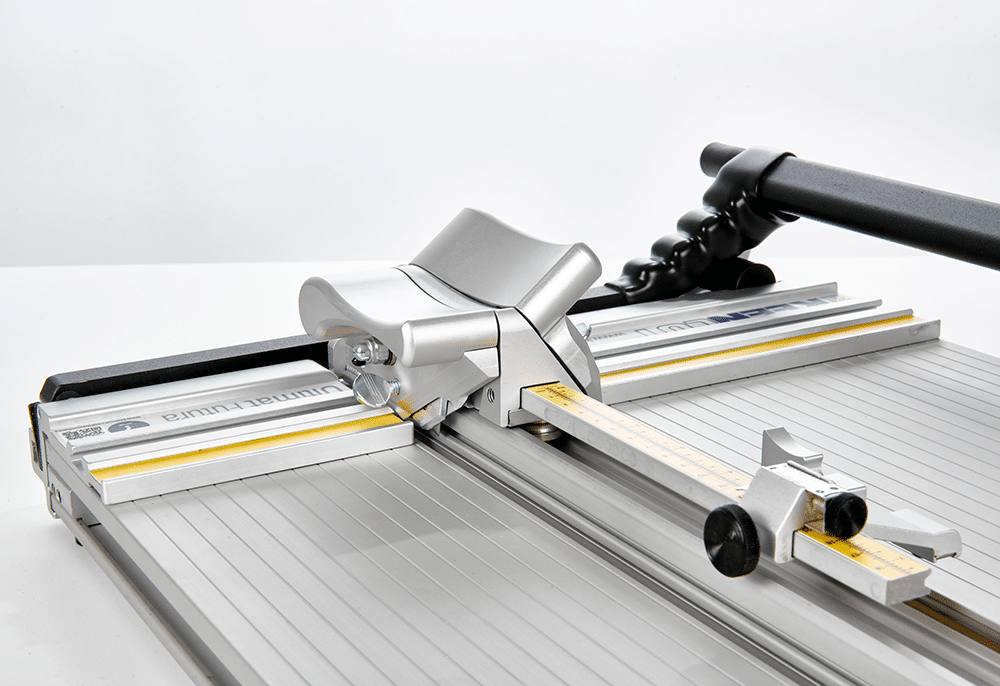

Perfect ergonomics

Shaped blade holders perfectly fit the hand to prevent finger strain when cutting even the toughest board. The head is comfortable to use for right or left-handed users and the cutter allows both hands to pull the blade holder when cutting.

Bevel & vertical blade holders

The switchable, magnetic blade holders make changing the blades for different depths of cut a simple and fast process. The vertical blade may be locked in the up position for safety, down for cutting regular board and left off for multi-stroke cutting of tough board.

Quick fitting interchangeable guides

The margin guide, squaring arm and optional board support are instantly removable for space-saving, or safety, when the machine is not in use. The instant clip-on/clip-off right squaring arm with repetition stop, is provided to accurately size all mountboards from 90cm (36”) down to 4cm (1.5”). Optional board supports are available to clip onto the base to hold large boards flat and square. The rigid T-bar margin guide is extendable up to 75cm (30”). The margin guide extension kit gives an accurate all-round location for the title box and multiple aperture cutting.

Five year guarantee

By manufacturing in-house, with only the highest quality materials, Keencut can guarantee that the Ultimat Futura will provide reliable long-lasting and accurate service. All Keencut products are offered with a comprehensive five year guarantee. Register your product to activate your guarantee >

In the box

15 Tech-S .015 blades

15 Tech-S .012 blades

30 Tech-D .012 blades

20 Keencut 080 superior quality blades

Materials cut

Mountboard

Conservation board

Foam centred board

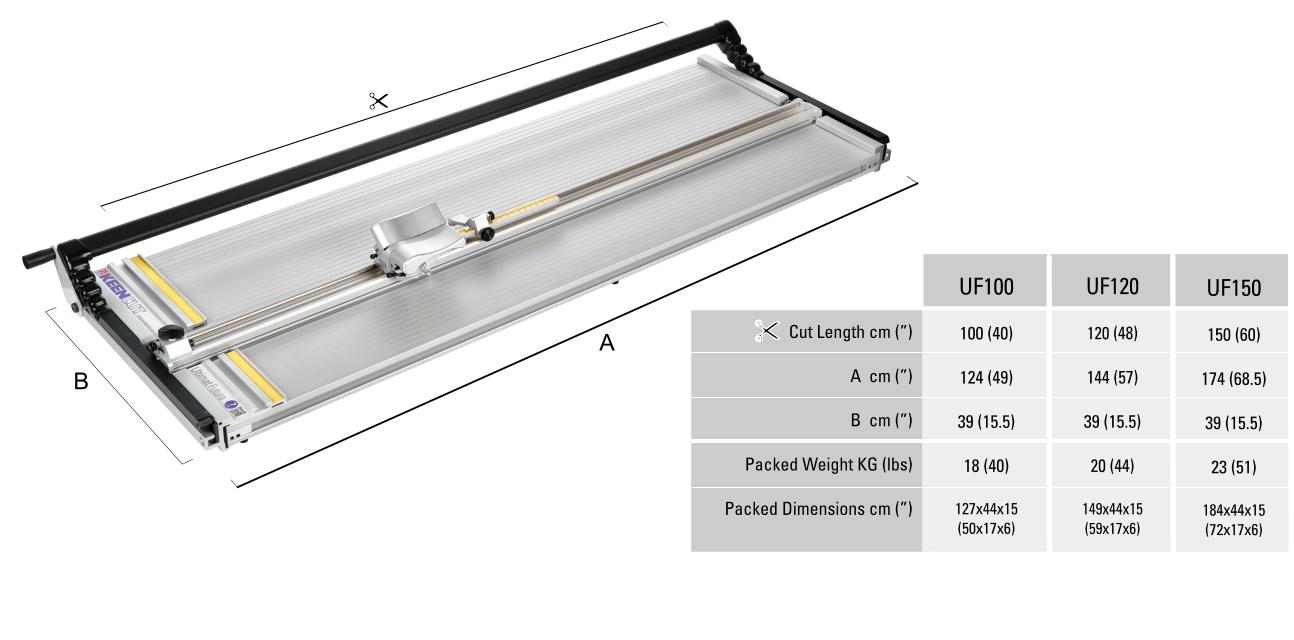

Dimensions

Reviews

"....the best in precision mount cutting."

“The easiest and quickest manual mount cutter I have ever used, the best in precision mount cutting.”

David Wilkie GCF of Silverstone Framing (UK) – http://www.silverstoneframing.com

Accessories

Ultimat Futura accessory pack

A complete accessory pack for those who need to accurately position extra-large boards or wish to easily undertake more creative cutting.

Product information >

75cm extension mat guide kit

Perfect for square, accurate position when cutting large mount boards, multiple openings, title boxes or just very wide margins.

Product information >

Multi-angle cutting gauges

Three different angled plates which clip instantly into the margin guide, giving predictable and accurate positioning for the mountboard to be marked or cut on an angle. The chosen angles were researched to provide creative scope to a framer with no need for fiddly adjustments. For special creative cutting, more than one angle plate can be located in the margin guide at one time.

Product information >

60cm support arms

Extension arms that clip on increasing the width of the base to 100cm (39”), to hold large boards flat and square by preventing sag. Use on the left with the margin guide, or on the right with the squaring arm.

Product information >

Reverse bevel stop

Add this to your cutter to produce a reversed bevel mat without over or under cuts. These mats can then accept ‘slips’ or ‘fillets’ producing a clean tight joint between the slip and the mat.

Product information >

Tech-D.012 blades

A pack of 100, double ground, 0.3mm (0.012”) thick blades, made from a high grade steel, giving increased durability and reduced blade tip wear/breakage. This blade is used for bevel and vertical cutting.

Product information >

Tech-D.015 blades

A pack of 100, double ground, 0.4mm (0.015”) thick blades made from a high grade steel, giving increased durability and reduced blade tip wear/breakage. Used for bevel cutting soft, thicker boards.

Product information >

Tech-S.012 blades

A pack of 100, single ground, chisel edge 0.3mm (0.012”) thick blades, made from a high grade steel, giving increased durability and reduced blade tip wear/breakage. Used for bevel cutting harder boards like conservation and white core boards up to 3mm (1/8″).

Product information >

Tech-S.015 blades

A pack of 100, single ground, chisel edge 0.4mm (0.015”) thick blades, made from a high grade steel, giving increased durability and reduced blade tip wear/breakage. Used for bevel cutting harder boards like conservation and white core boards thicker than 3mm (1/8″).

Product information >

Keencut-080 superior quality blades

A pack of 100, double ground edge 0.43mm (0.017”) thick blades, made from a high grade steel, giving increased durability and reduced blade tip wear/breakage. The blades can be used for vertical cutting.

Product information >

Futura squaring arm

Easy clip on and off arm to help cut material precisely square to a pre-determined size whilst providing additional material support.

Product information >