Worktop Material Guide Installation Manual – Installation

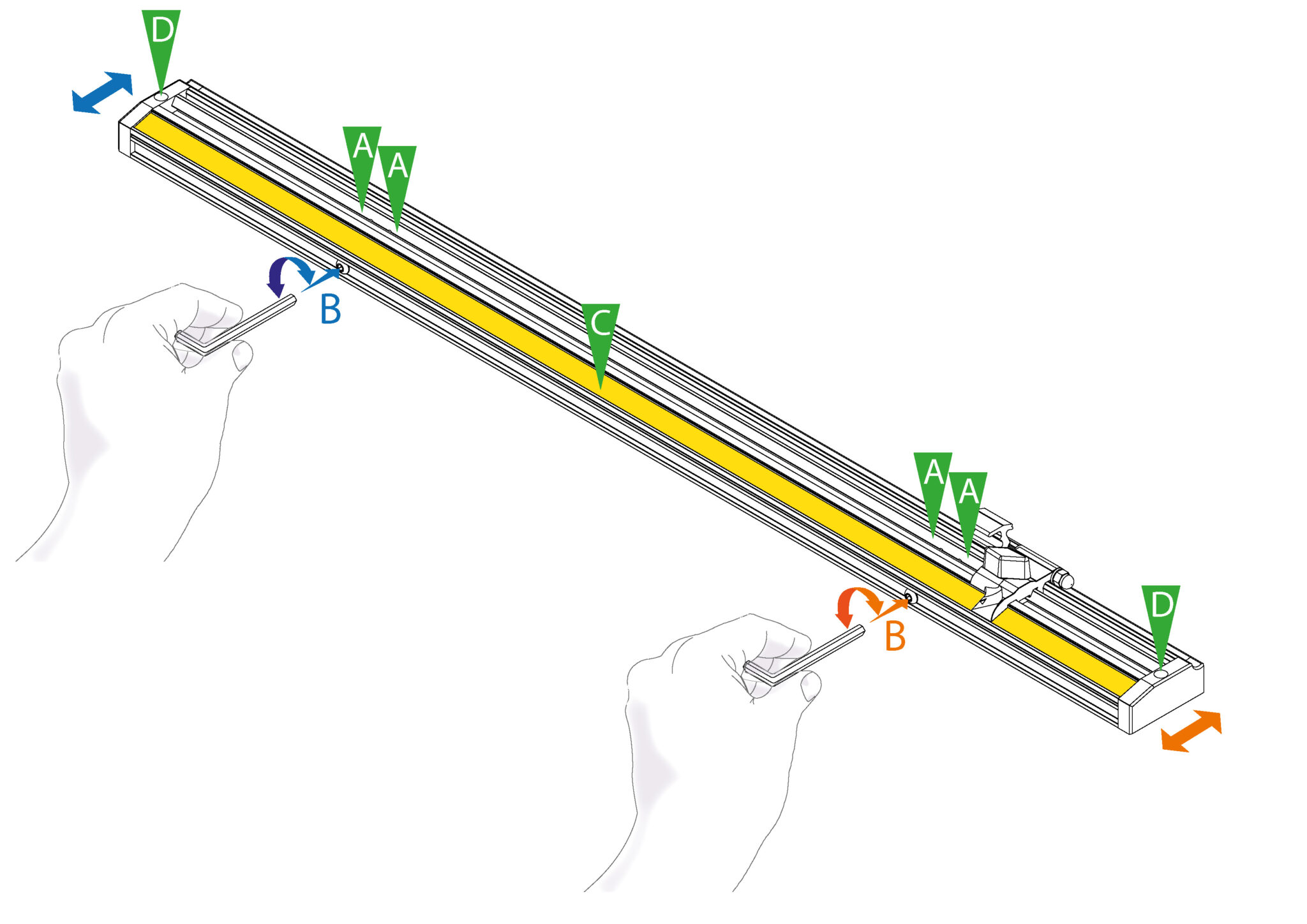

The installation process should follow a set procedure:

A. Place the Material Guide in its approximate position and fix down using the four in-board screws.

B. The two adjusters can then be used to fine-tune its position and angle:

– By rotating both adjusters the same amount the Material Guide will move parallel forward or back.

– By rotating either one of the adjusters the Material Guide will alter its angle.

C. Once fully aligned fix and calibrate the measuring scale.

D. Slide on the measuring stop and push on the two end caps. Insert the two screws in the plastic end caps to fix its position.

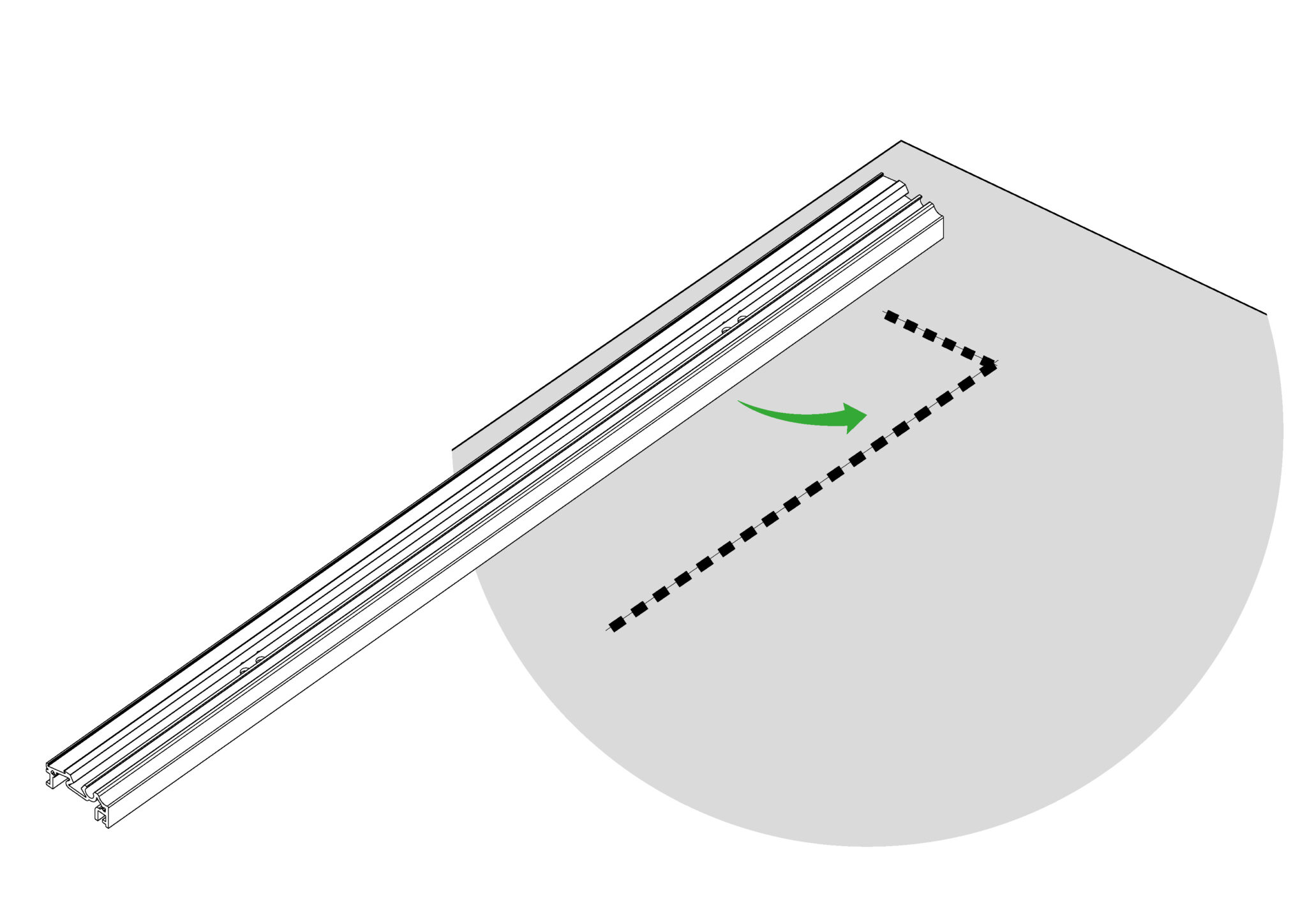

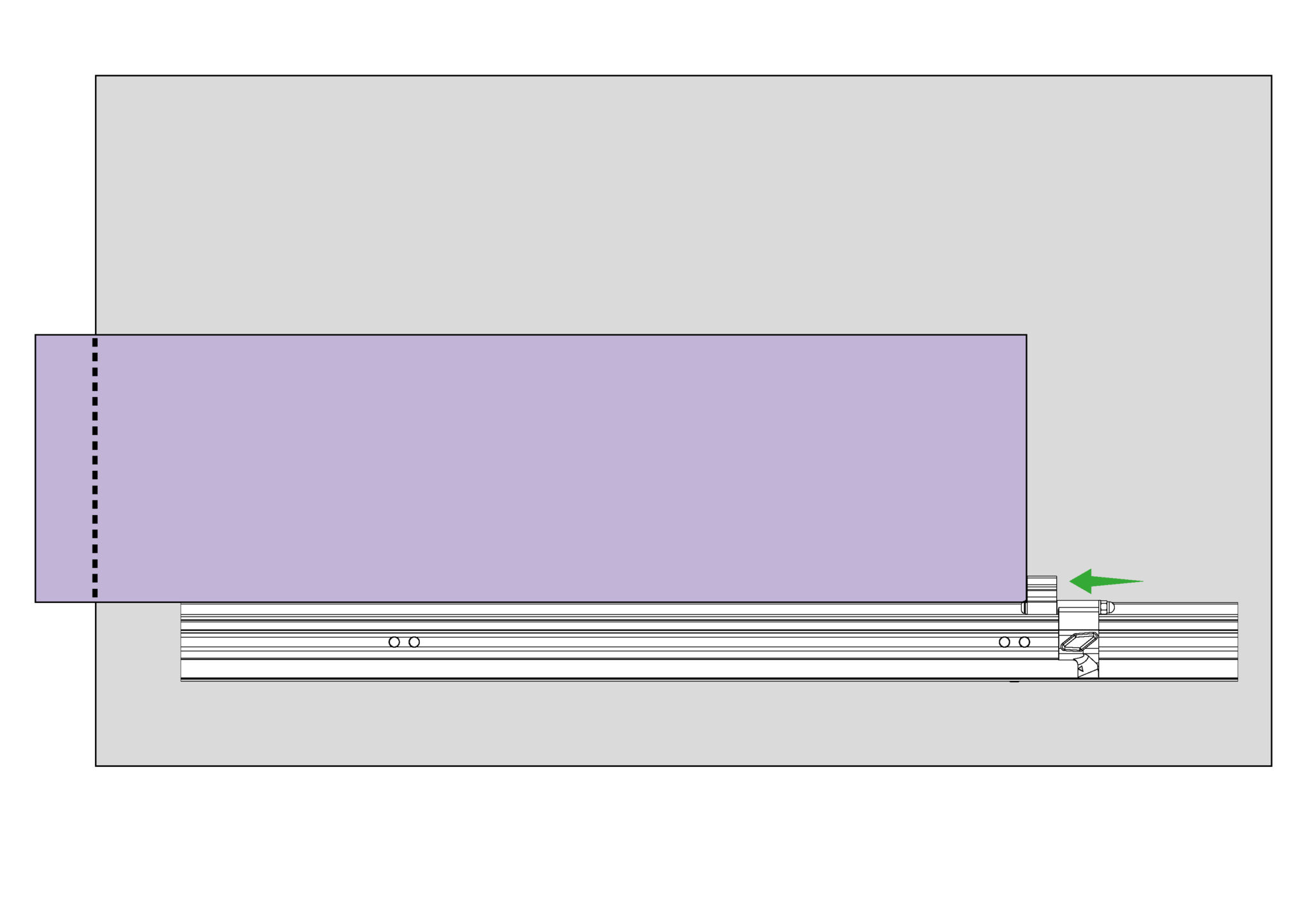

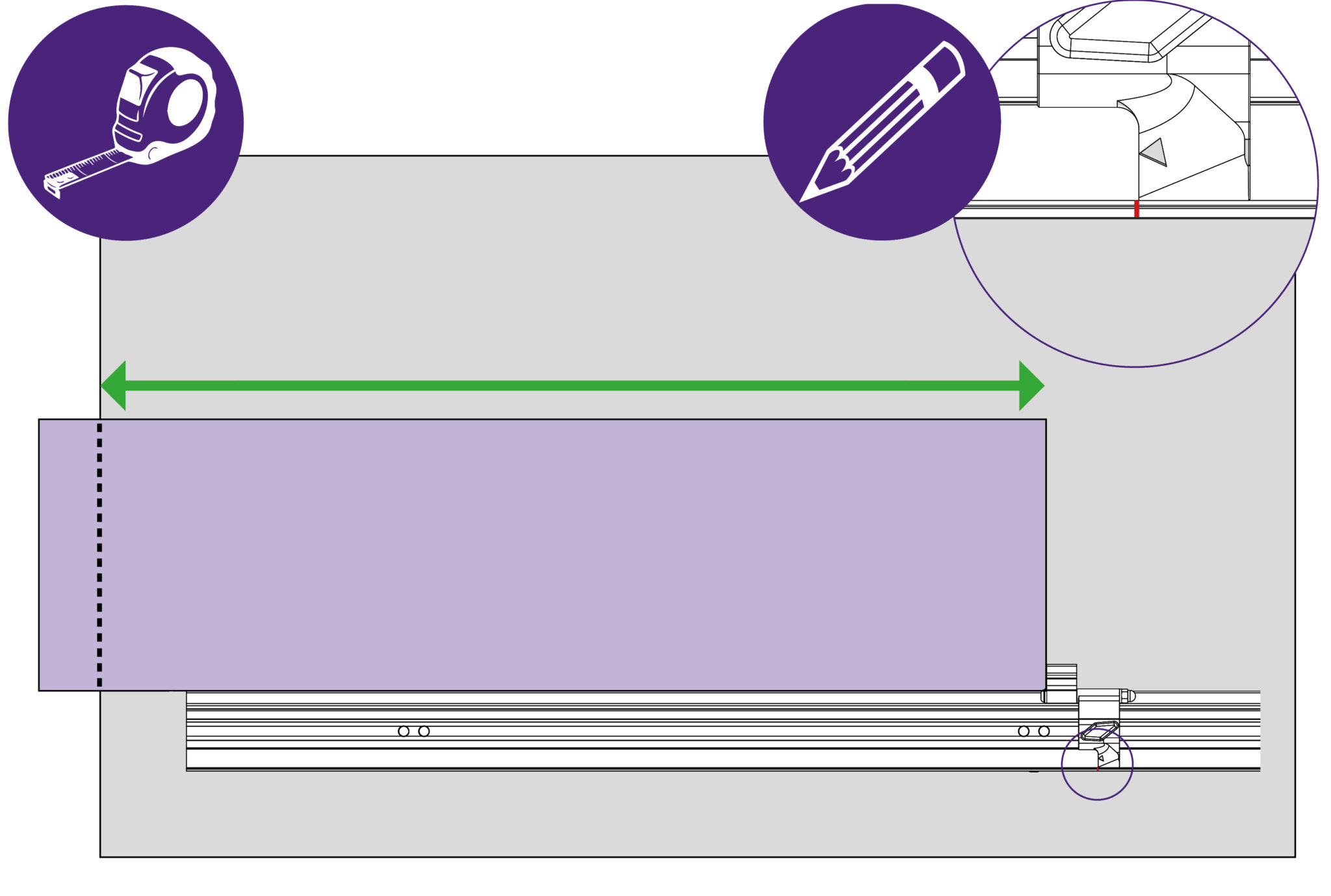

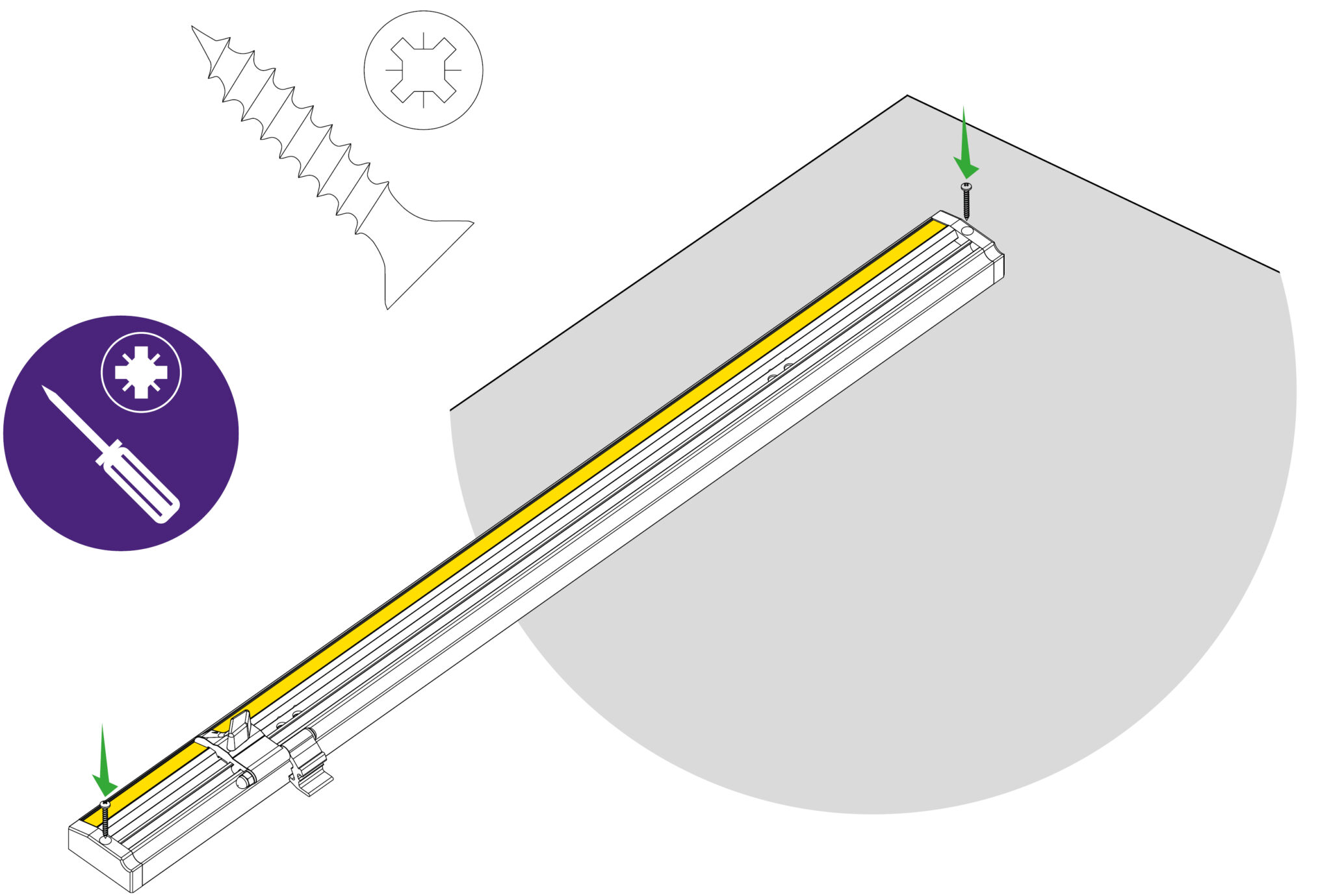

Lay the Material Guide in the desired position to guide the left or right-hand side of the work piece (following drawings show it fitted on the right), use measured pencil lines or paper tape to assist. If it is to be aligned with another guide/object use a straight edge or the edge of a large piece of board to help.

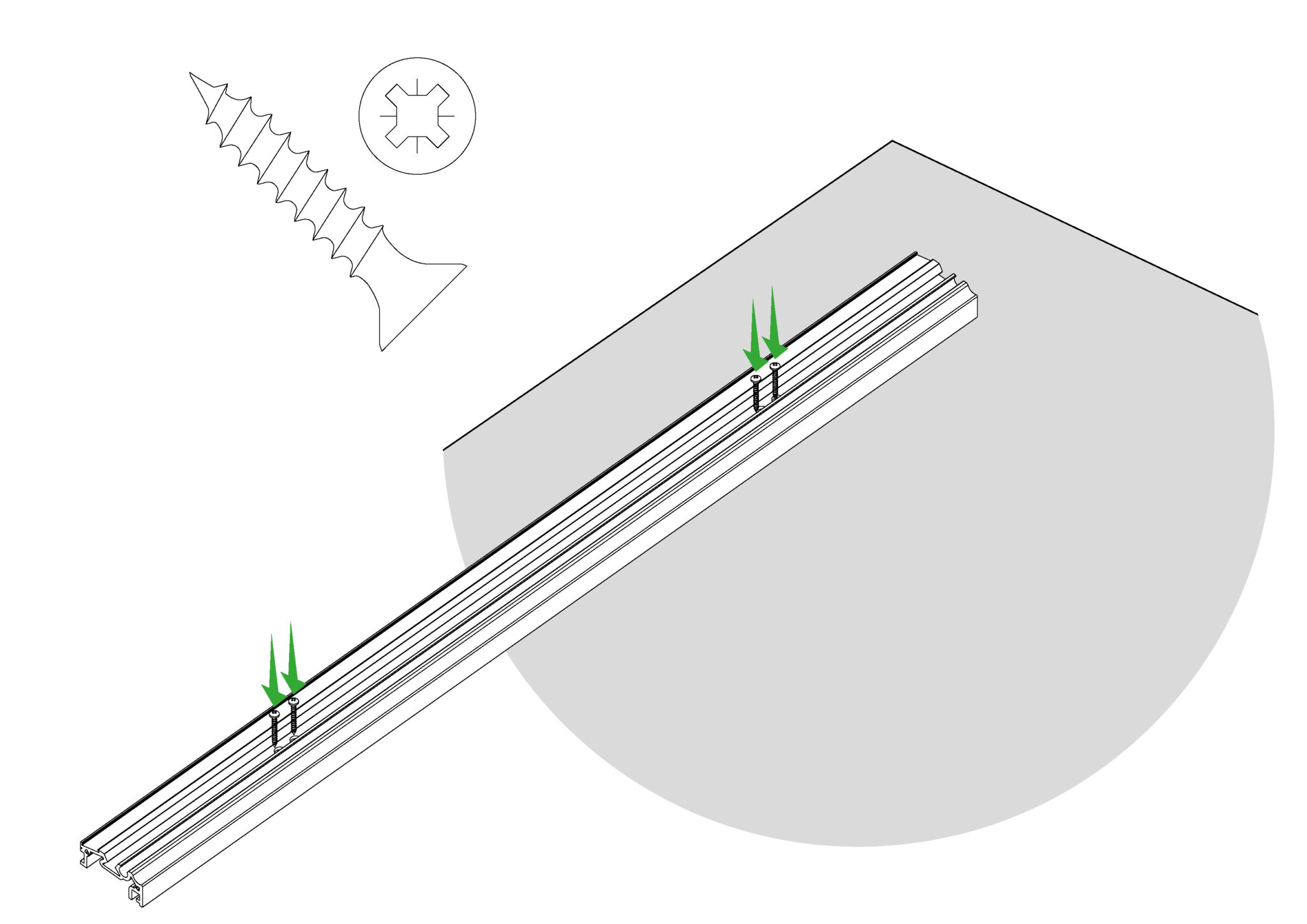

IMPORTANT: Ensure that enough space is left for when the end caps are installed at a later stage

Once you are happy with the location, use a posi head screwdriver to fix the Material Guide in position using 4 of the wood screws.

IMPORTANT: DO NOT fix the plastic end caps at this stage, this is to be completed after the Material Guide has been calibrated.

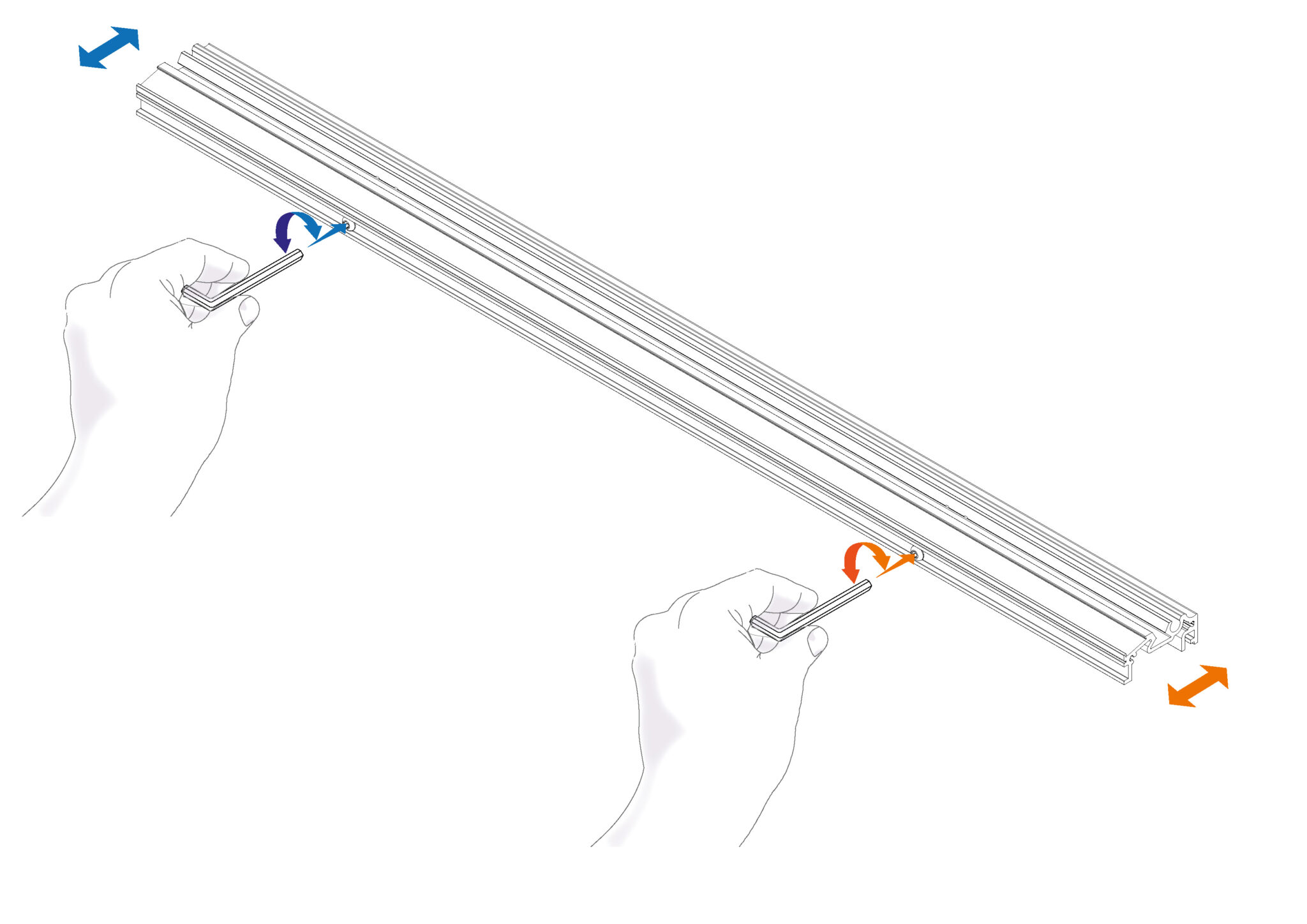

Fine squaring corrections can be made using a 4mm Allen (hex) in the two squaring adjusters.

Firstly, make any required adjustment to the angle of the Material Guide. This can be carried out using either adjustment screw. When turning the screw clockwise the Material Guide at that point advances, rotating the guide about the other adjuster.

Need help checking it is at 90 degrees when installed with a cutter? Go to Squaring check >

Once the angle has been adjusted, if the Material Guide needs to move parallel to align with another object/edge rotate both screws by equal amounts. As a guide, one full rotation of the screw equals 1mm (0.040”).

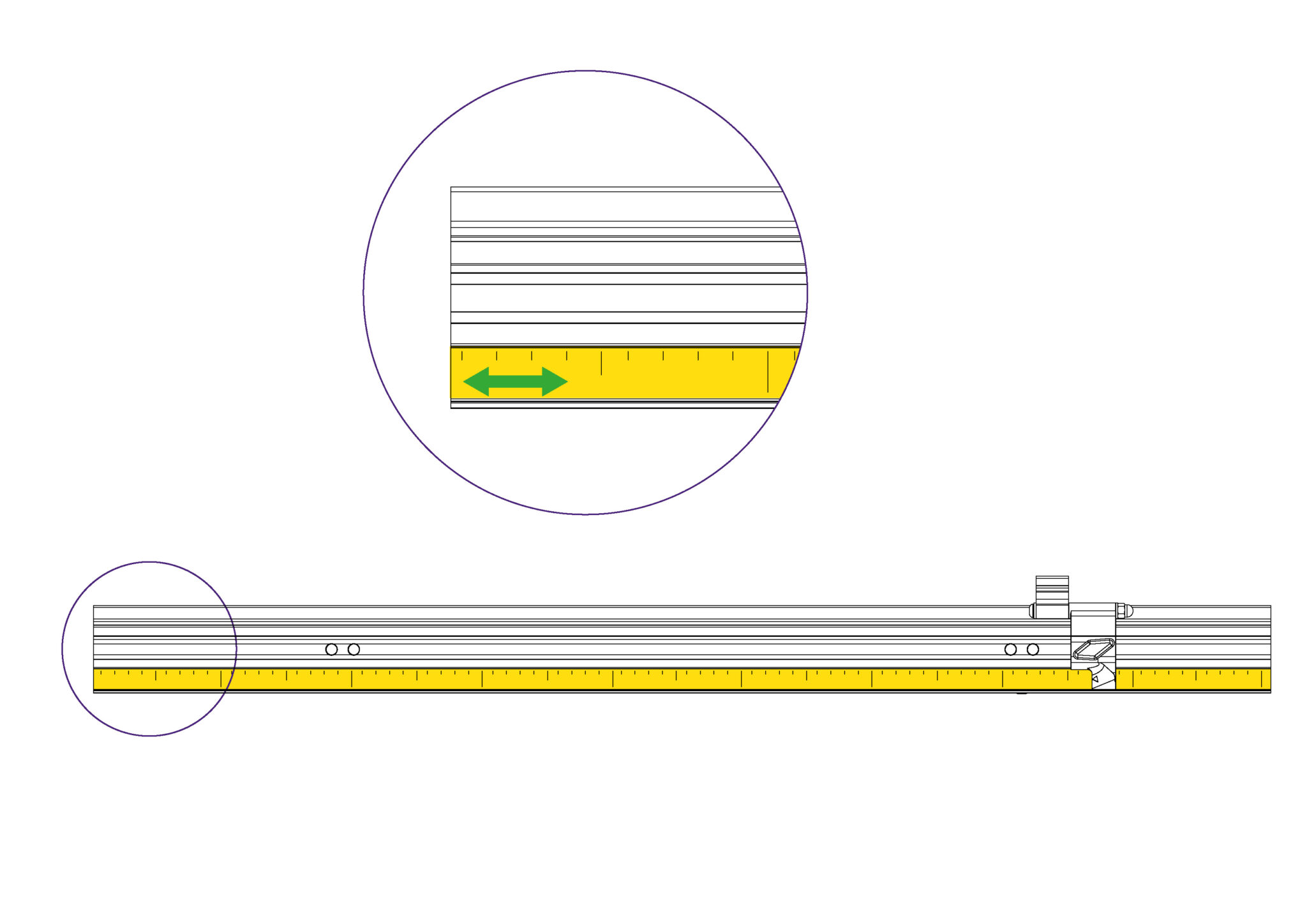

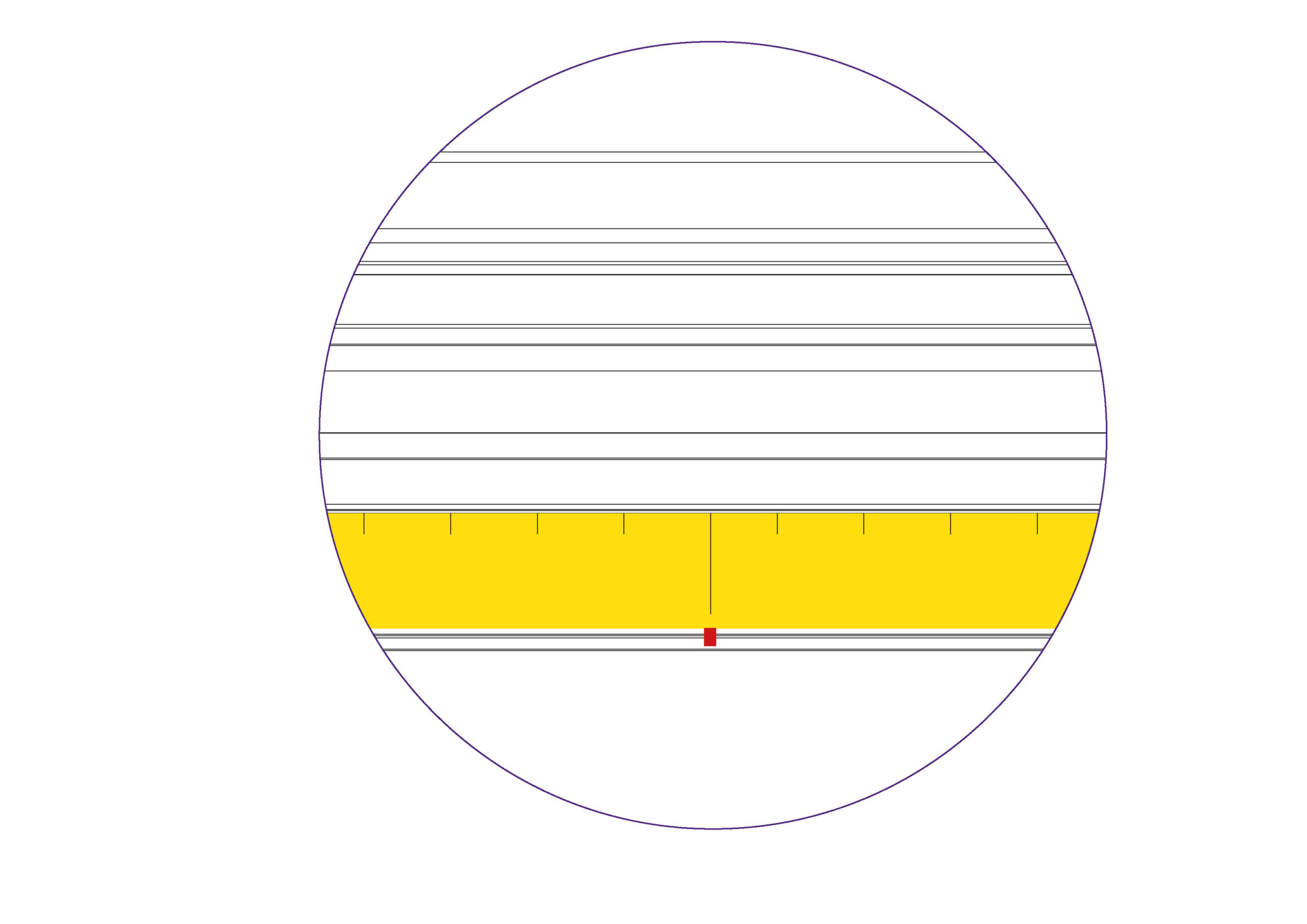

The self-adhesive measuring scale fixes to a stainless-steel strip which can be slid to make small calibrations once it is stuck in place. Ensure the strip is centralised before proceeding.

Two measuring scales are supplied one reading left to right the other right to left.

Take a piece of rigid card or similar board around 50cms (18”) long and place it against the Material Guide such that one end overlaps the ‘zero’ position.

Slide the measuring stop onto the Material Guide and fasten it in position against the edge of the board.

Either mark or cut the board at the zero position. Note the measurement of the board from the zero position to the edge against the measuring stop. Make a pencil mark on the aluminium extrusion as shown. Remove the measuring stop.

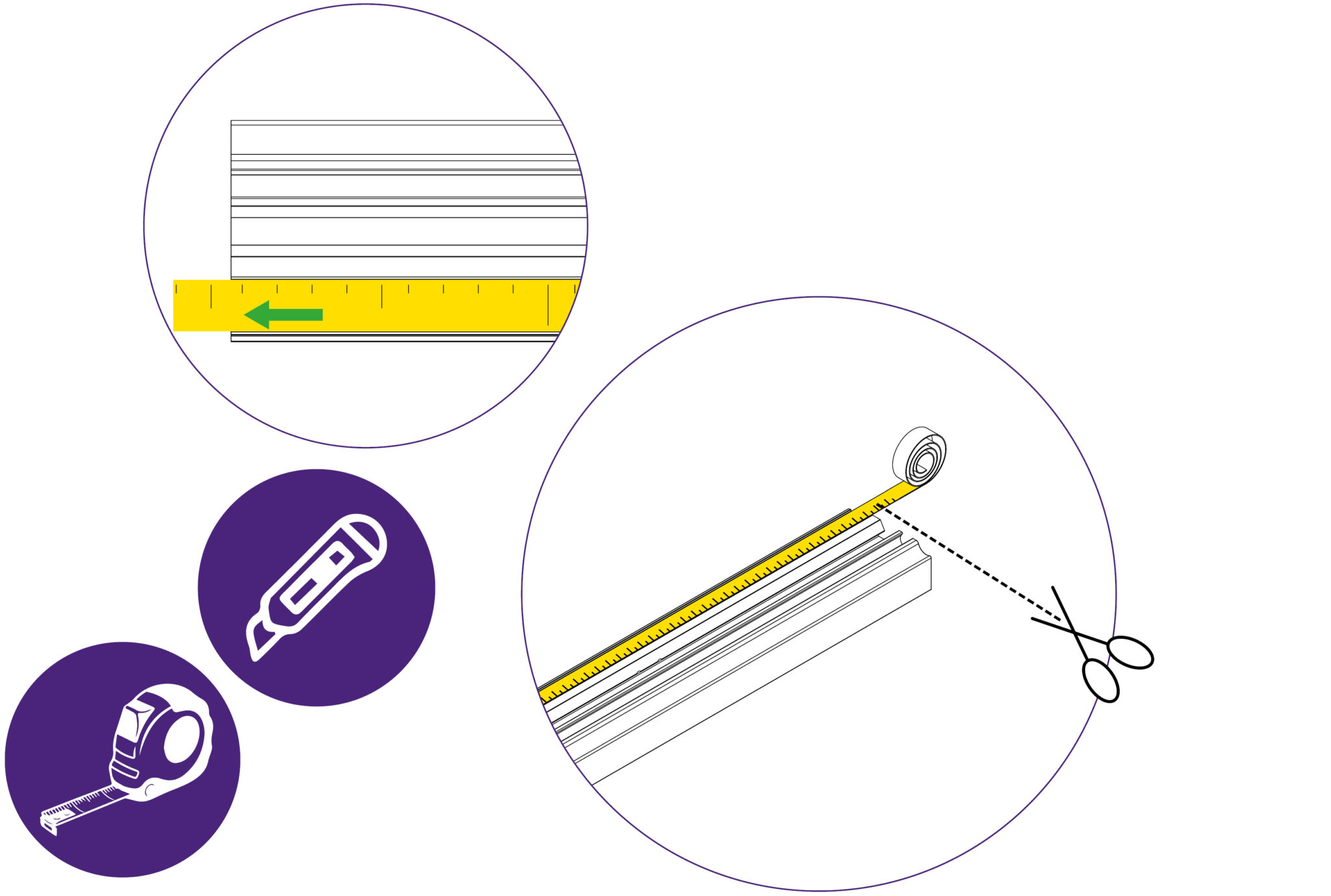

Select the measuring scale and remove around 15cms (6”) of the backing paper from one end. Position the measured dimension on the scale adjacent to the pencil mark. Hold in position and press down the end of the scale to stick it in place. Peel off the remainder of the backing paper and press firmly on the scale to fix it in position.

Check the scale measures accurately and make any fine adjustments by pressing down on the scale with finger and thumb and sliding

Once the scale sticker is firmly attached, slide the measuring scale out of the Material Guide to give easy access to the end of the measuring scale. Trim the excess using a craft knife.

Slide the measuring scale back into position, Check the scale measures accurately, and make any fine adjustments by pressing down on the scale with finger and thumb and sliding left or right.

The installation process should follow a set procedure:

A. Place the Material Guide in its approximate position and fix down using the four in-board screws.

B. The two adjusters can then be used to fine-tune its position and angle:

– By rotating both adjusters the same amount the Material Guide will move parallel forward or back.

– By rotating either one of the adjusters the Material Guide will alter its angle.

C. Once fully aligned fix and calibrate the measuring scale.

D. Slide on the measuring stop and push on the two end caps. Insert the two screws in the plastic end caps to fix its position.

Lay the Material Guide in the desired position to guide the left or right-hand side of the work piece (following drawings show it fitted on the right), use measured pencil lines or paper tape to assist. If it is to be aligned with another guide/object use a straight edge or the edge of a large piece of board to help.

IMPORTANT: Ensure that enough space is left for when the end caps are installed at a later stage

Fine squaring corrections can be made using a 4mm Allen (hex) in the two squaring adjusters.

Firstly, make any required adjustment to the angle of the Material Guide. This can be carried out using either adjustment screw. When turning the screw clockwise the Material Guide at that point advances, rotating the guide about the other adjuster.

Need help checking it is at 90 degrees when installed with a cutter? Go to Squaring check >

Once the angle has been adjusted, if the Material Guide needs to move parallel to align with another object/edge rotate both screws by equal amounts. As a guide, one full rotation of the screw equals 1mm (0.040”).

The self-adhesive measuring scale fixes to a stainless-steel strip which can be slid to make small calibrations once it is stuck in place. Ensure the strip is centralised before proceeding.

Two measuring scales are supplied one reading left to right the other right to left.

Take a piece of rigid card or similar board around 50cms (18”) long and place it against the Material Guide such that one end overlaps the ‘zero’ position.

Slide the measuring stop onto the Material Guide and fasten it in position against the edge of the board.

Either mark or cut the board at the zero position. Note the measurement of the board from the zero position to the edge against the measuring stop. Make a pencil mark on the aluminium extrusion as shown. Remove the measuring stop.

Select the measuring scale and remove around 15cms (6”) of the backing paper from one end. Position the measured dimension on the scale adjacent to the pencil mark. Hold in position and press down the end of the scale to stick it in place. Peel off the remainder of the backing paper and press firmly on the scale to fix it in position.

Check the scale measures accurately and make any fine adjustments by pressing down on the scale with finger and thumb and sliding

Once the scale sticker is firmly attached, slide the measuring scale out of the Material Guide to give easy access to the end of the measuring scale. Trim the excess using a craft knife.

Slide the measuring scale back into position, Check the scale measures accurately, and make any fine adjustments by pressing down on the scale with finger and thumb and sliding left or right.