How to replace the pivot housing assembly on the SteelTrak 250 only

To do this you will need the SteelTrak & Excalibur pivot housing assembly >

Tools required:

- Allen (hex) key 4, 5 & 6mm

- Small flat screwdriver or steel rule

- 10mm open ended spanner/wrench

- Hand protection

- Steps to access the top of the machine

What to do

NOTE: A minimum of two able bodied people are required to carry out this work. The cutter bar and cutting head need to be removed. It is also important for the instructions to be read and understood before commencing.

The instructions below assume the SteelTrak remains in its vertical installed position for the replacement. However, if preferred the machine can be disconnected from its wall bracket and laid on the floor to work on.

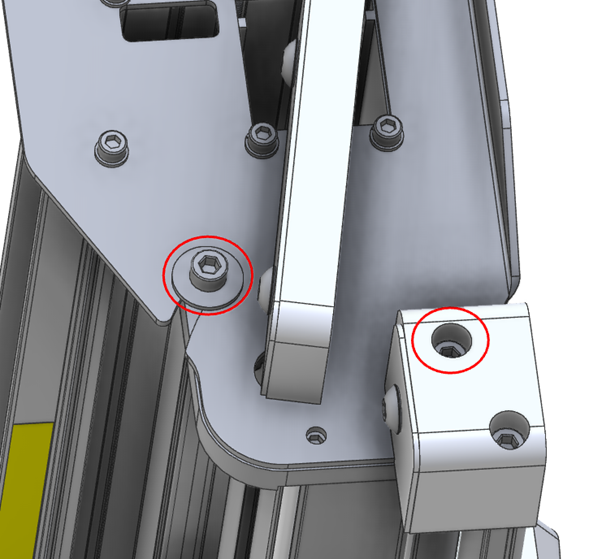

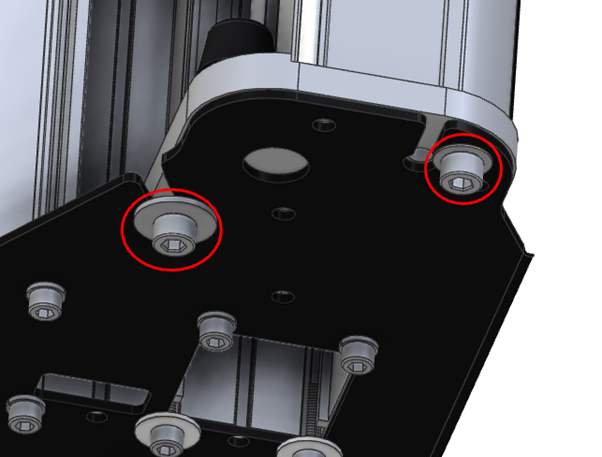

- Remove all blades from the cutting head then to remove the cutting head, loosen the top and bottom handle bracket screws by four full turns using the 4mm Allen (hex) key. Do not loosen the middle screw. Loosen the two spring bar fixing screws by four full turns using the 5mm Allen (hex) key. The cutting head should now come loose on the cutter bar and can be carefully moved to the left to disengage it. The Balance Weight Cable will still be attached and prevent it from falling but do not let go of the cutting head, keep it fully supported at all times.

- Disconnecting the cable will require two people and a pair of steps or a ladder to enable access to the top left hand side of the machine.

- Position the steps or ladder as explained above.

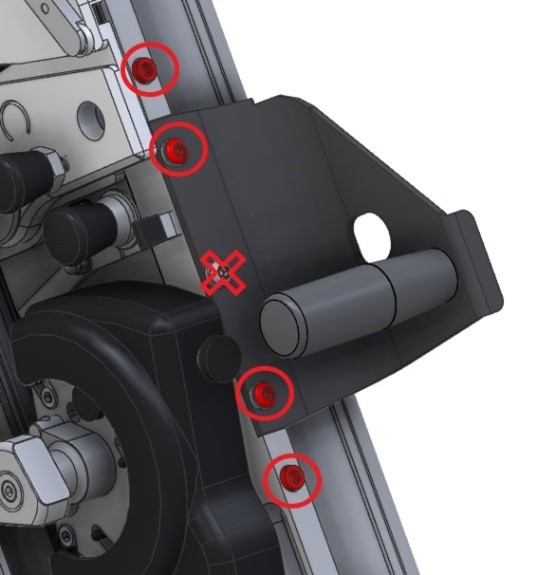

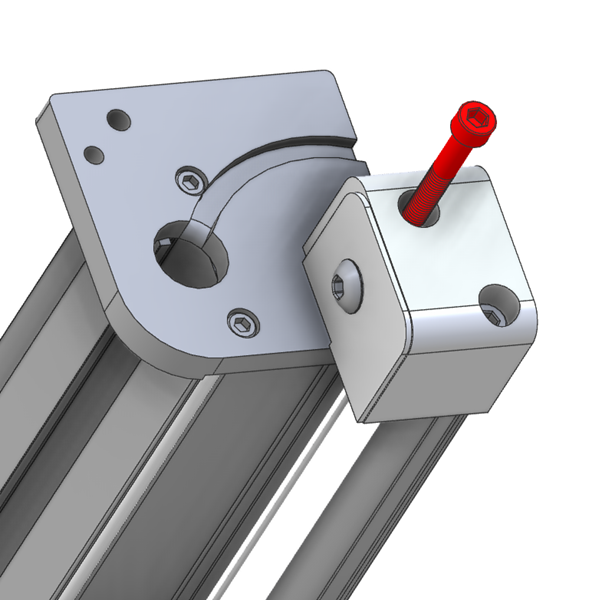

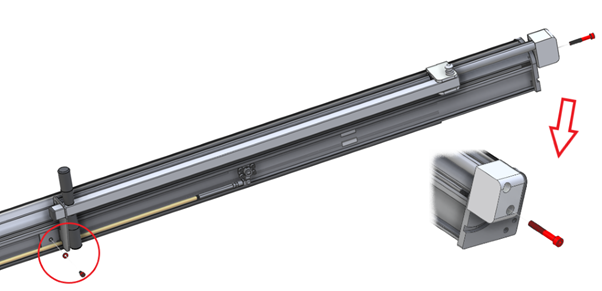

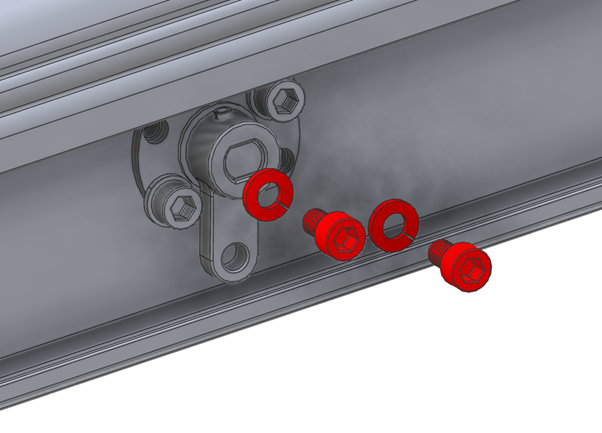

- Disconnecting the cutter bar; one person must hold the cutter bar onto the machine whilst the other removes the following screws.

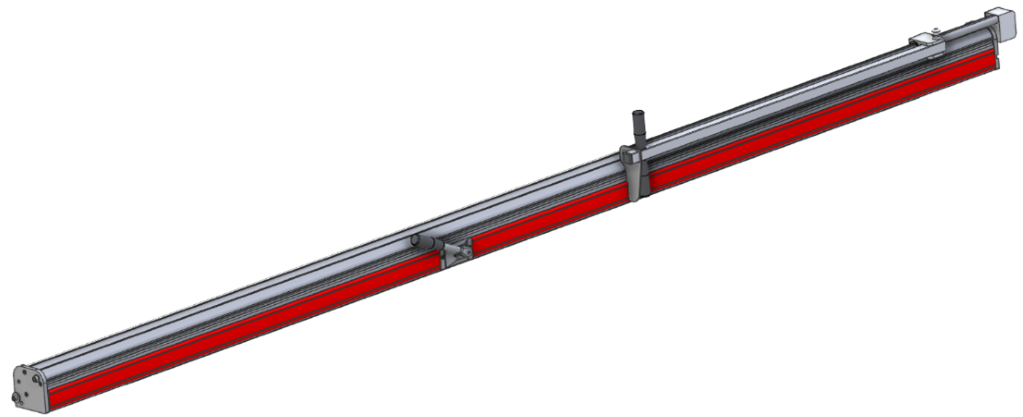

The cutter bar assembly is very heavy and should only be lifted by two people

- Take the weight of the cutter bar and pull it out at the bottom to clear the fixing plate then lower it to the ground. Be careful that end of the balance weight cable is not caught in the top of the cutter bar.

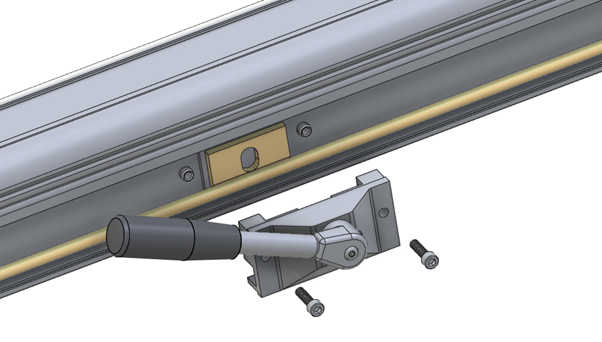

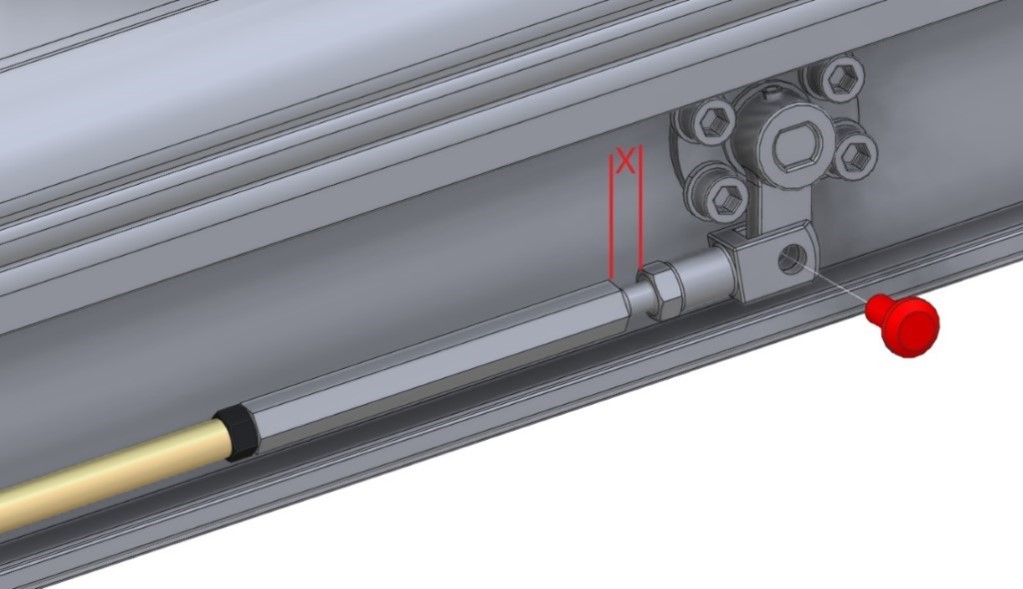

- Rotate the Adjuster to close the gap between itself and the forked fitting as much as possible, sometimes this can be done using your fingers rather than the spanner/wrench.

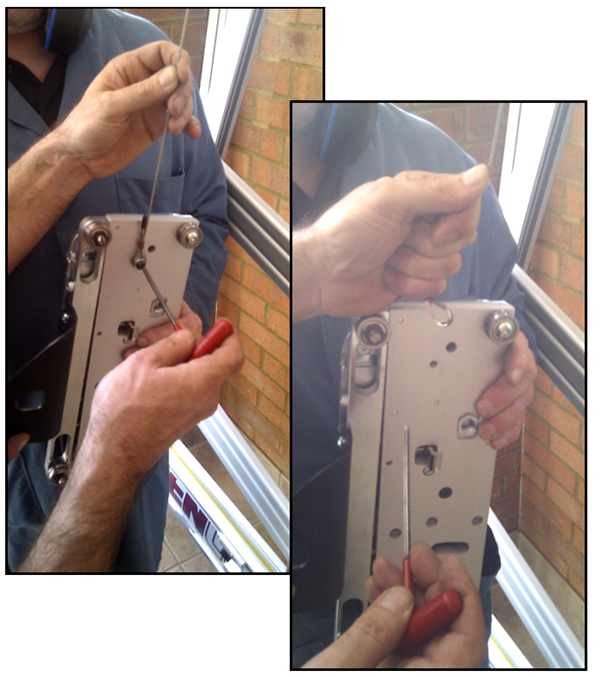

- Remove the pin from the lower forked fitting.

- Remove the push rod, on some versions the push rod may need to be flexed slightly to remove it.

- REASSEMBLY – replace the pivot housing in the reverse order but care needs to be taken in the following areas:

-

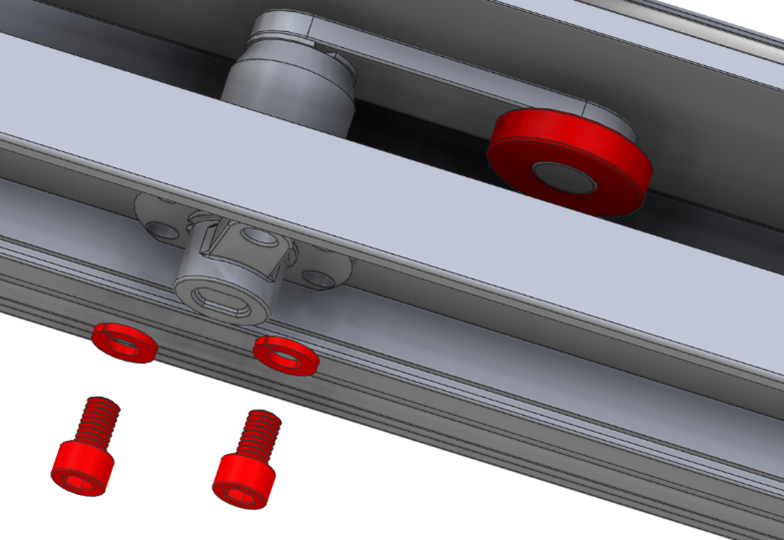

- When fitting the clamp bar introduce the bottom pressure roller into its groove and push the roller down into the groove with your finger as you push the clamp bar into position. Introduce the top pressure roller into its groove and again push it down with your finger to locate it, push the clamp bar all the way into the cutter bar.

- If necessary use the 10mm spanner/wrench to adjust the clamp bar to make it parallel to the back of the main machine.

- Once fully assembled adjust the maximum clamping pressure. Using the 3mm Allen (hex) key, turn both grub screws on the face of the clamp handle housing clockwise until they stop then undo each screw by ¼ turn, further small adjustments can be made to increase or decrease the maximum clamping pressure as desired.